How can I import custom solar panels from China and customize cable length and gauge?

Many buyers accept default cables. Later they face voltage loss, messy wiring, or failed inspections. These small decisions quietly reduce system performance.

From my experience, importing custom panels with tailored cable length and gauge improves efficiency, safety, and installation speed when specifications are calculated and communicated clearly.

When I place OEM orders in China, I always treat cables as part of the electrical design. Factories can customize them precisely. But results depend on clear calculations, drawings, and inspection steps.

How do I calculate correct wire size?

Choosing cable gauge should never be guesswork. I always start with electrical limits and safety margins.

Correct wire size depends on current rating1, voltage drop tolerance, and certification compliance.

Determining current requirements

I base cable size on panel short circuit current.

I use a safety factor of 1.25 times Isc.

This ensures the conductor operates within safe thermal limits.

| Parameter | Example | Purpose |

|---|---|---|

| Panel Isc | 11 A | Baseline current |

| Safety multiplier | ×1.25 | Thermal margin |

| Required rating | 13.75 A | Cable sizing target |

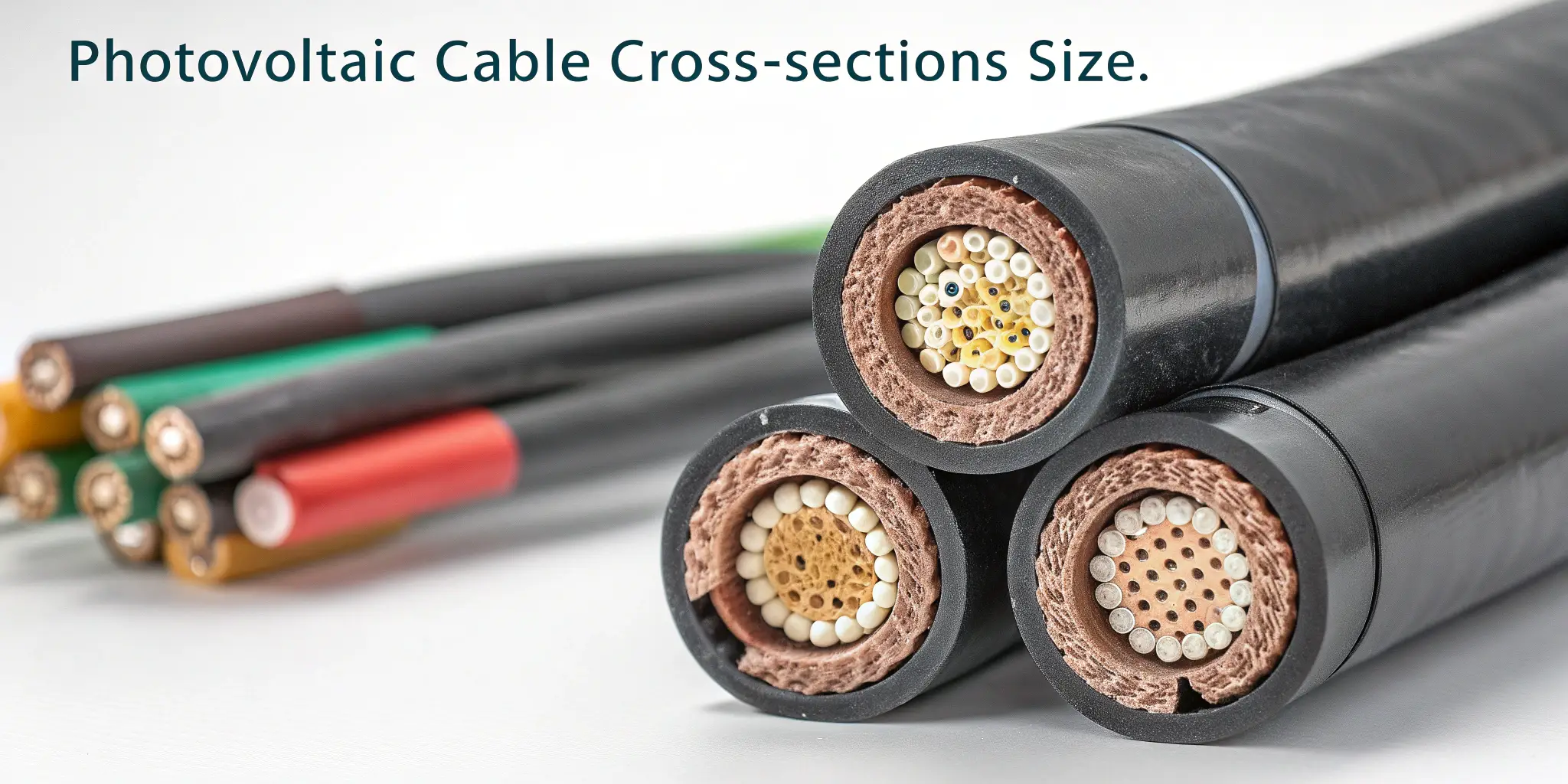

Selecting cross-section area

Common OEM choices include:

- 2.5 mm²

- 4 mm²

- 6 mm²

I match these against the required current rating and certification limits.

Certification and insulation

I specify PV-rated cables2 such as:

- IEC 62930

- EN 50618

- UL 4703

I also define insulation type like XLPE for outdoor exposure. This ensures UV and moisture resistance.

How do longer cables affect voltage drop3?

Cable length directly affects power delivery. I never assume factory defaults are sufficient.

Longer cables increase resistance and cause voltage drop.

Understanding voltage loss

Voltage drop reduces system efficiency.

I calculate it before ordering.

The main factors are:

- Cable length

- Current

- Cross-section

| Cable Length | Gauge | Expected Drop |

|---|---|---|

| Short | Large | Low |

| Long | Small | High |

Practical design choices

When I need longer leads, I compensate by:

- Increasing cable gauge

- Reducing routing distance

- Relocating junction boxes

This balances efficiency and cost.

Factory validation

I ask suppliers to confirm voltage drop calculations. This double check reduces risk before production begins.

Can suppliers adjust cables precisely?

Most Chinese manufacturers support detailed customization. Accuracy depends on specification quality.

Factories can produce precise cable assemblies4 when requirements are measurable and documented.

Technical documentation

I always define:

- Length measured from junction box to connector

- Tolerance of ±2 cm

- Connector orientation

This prevents confusion during assembly.

Connector compatibility

I lock connector models such as:

- MC4 compatible connectors

- Matching crimp profiles

This avoids electrical mismatch with chosen gauge.

Sampling and verification

Before mass production, I request sample panels.

I inspect:

- Cable routing

- Bend radius

- Strain relief

This ensures cables integrate with mounting systems.

What common wiring mistakes affect performance?

Cable customization solves many issues. But poor planning introduces new risks.

I regularly see avoidable mistakes that harm reliability.

Undersized conductors5

Some buyers focus on cost and select smaller gauge cables.

This causes overheating and power loss.

I always size conductors above minimum requirements.

Poor crimp quality6

Connector failure often traces back to weak crimps.

I require pull testing and polarity checks during inspection.

Lack of labeling and color coding

Field installers rely on clear identification.

I specify marking and color standards to reduce wiring errors.

Ignoring mechanical stress

Long cables move in wind or vibration.

I require strain relief design and tensile strength checks to prevent junction box damage.

Conclusion

From my experience, cable customization shapes system efficiency and safety. When importing panels from China, proper calculations, documentation, and inspection ensure customized wiring delivers real value.

-

Understanding current rating is crucial for ensuring safety and efficiency in electrical installations. ↩

-

Exploring PV-rated cables will help you understand their significance in solar applications and compliance. ↩

-

Understanding voltage drop is crucial for optimizing electrical systems and ensuring efficiency. Explore this link for in-depth insights. ↩

-

Understanding cable assemblies can help you grasp their customization options and applications in various industries. ↩

-

Understanding the impact of undersized conductors can help you avoid overheating and power loss in your electrical systems. ↩

-

Exploring the effects of poor crimp quality can enhance your knowledge on ensuring reliable electrical connections and preventing failures. ↩