Do Floating Solar Farms Need Special MC4 Connectors?

Floating solar projects are growing fast, but standard components face new environmental threats like humidity and corrosion.

Yes, floating solar farms require specially designed MC4 connectors that can resist water, UV, and corrosion damage over time.

With increasing adoption of floating solar around the world, understanding how MC4 connectors perform in water-heavy environments is critical. Let’s explore why special connectors are necessary and how leading brands handle it.

What Are the Environmental Challenges Faced by MC4 Connectors in Floating Solar Projects?

Floating PV systems face different conditions than land-based installations. Heat, salt, moisture, and UV radiation1 are constant threats.

Floating solar environments expose connectors to corrosion2, UV, saltwater spray, and temperature swings — all of which can degrade normal MC4 connectors3.

Key Factors That Affect Connector Durability

| Challenge | Impact on MC4 Connectors |

|---|---|

| Constant moisture | Increases risk of internal corrosion and seal failure |

| Salt or minerals | Accelerates metal oxidation and degradation |

| UV radiation | Weakens plastic housing, cracks over time |

| Floating platform movement | Stresses connections, leads to potential loosening or leakage |

| Temperature cycles | Expands and contracts materials, wearing seals |

These environmental stressors don’t exist to the same extent in rooftop or ground-mounted systems. That's why connector choice is more critical on water.

How Does Constant Water Exposure Affect Standard MC4 Connectors?

Even “waterproof” land-based connectors are not designed for long-term immersion or splash zones.

Standard MC4 connectors4 may degrade when used in floating PV systems5, leading to safety issues or power loss.

The Risks of Using Non-Marine-Grade MC4s

- Seal breakdown: Gasket materials in standard connectors can absorb moisture.

- Internal corrosion: Even gold or silver-plated contacts can corrode if improperly sealed.

- Heat buildup: Poor connections increase resistance and can lead to thermal runaway.

- Short circuits: Water intrusion may bridge contacts.

If connectors fail, floating solar systems can lose output, suffer downtime, or in the worst case, pose a fire hazard.

Are There Waterproof or Marine-Grade MC4 Connectors Available?

Yes — and they’re built specifically to withstand marine and floating environments.

Marine-grade MC4 connectors6 offer superior sealing, corrosion resistance, and long-term UV protection.

What Makes a Waterproof MC4 “Marine-Grade”?

| Feature | Marine-Grade MC4 | Standard MC4 |

|---|---|---|

| IP Rating | IP68 (submersible)7 | IP65 or IP67 |

| Contact Plating | Tin + heavy silver or gold | Standard tin or silver |

| Housing Material | UV-stabilized, anti-salt | Basic UV-stabilized plastic |

| Cable Gland | Enhanced water-tightness | Standard seal |

| Long-Term Corrosion Testing | >1000 hours salt spray | 240–500 hours |

Brands like Stäubli offer IP68-rated MC4-Evo 2 connectors, which are widely used in wet or marine applications due to their reliability and precision engineering.

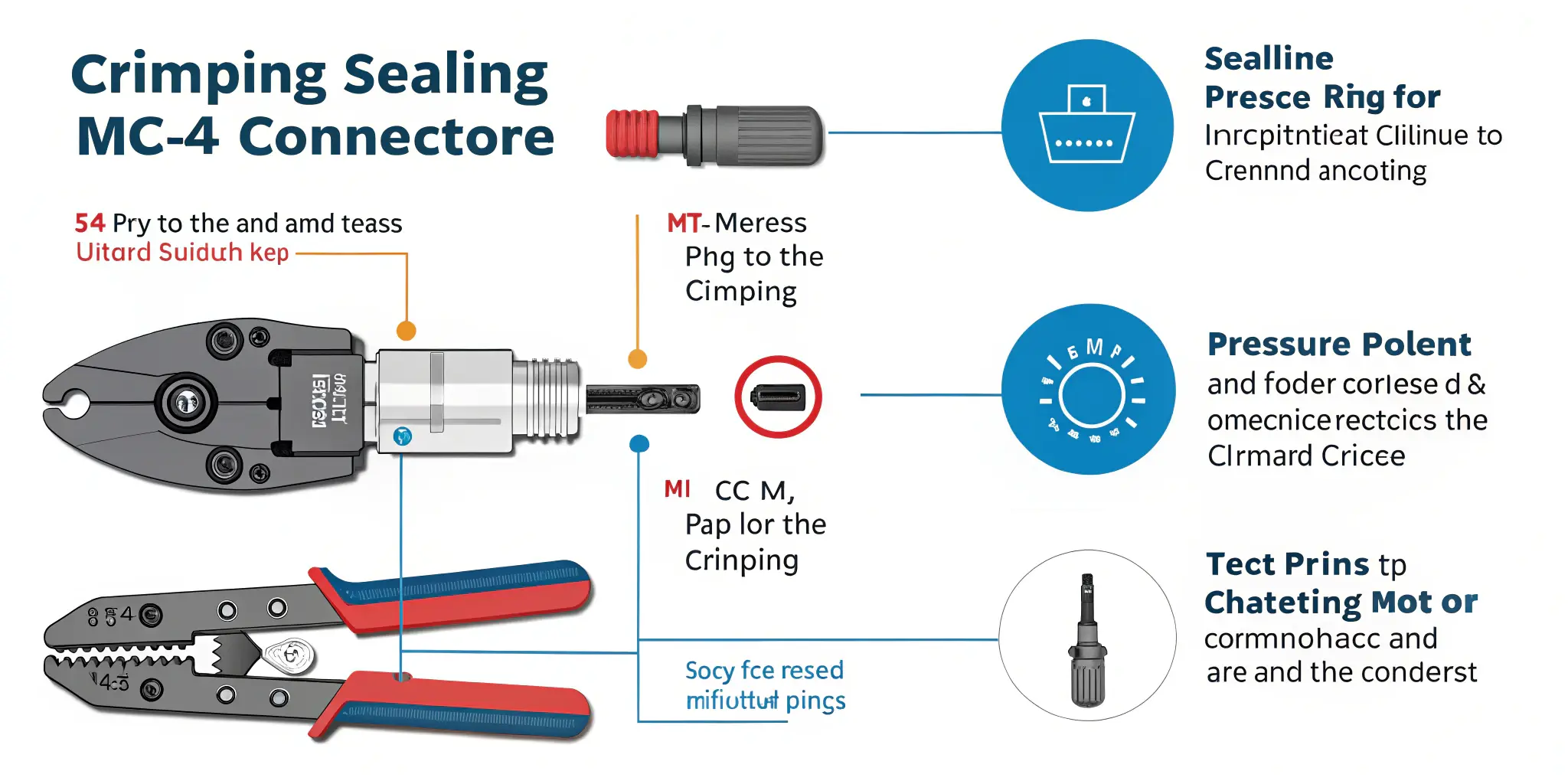

What Are the Best Practices for MC4 Connector Installation in Floating PV Systems?

Proper installation is just as important as the connector’s quality. Even the best MC4s can fail if they’re not handled well.

Use marine-grade tools8, avoid field-assembled connections, and always follow IP68-rated crimping and sealing procedures.

Best Practices to Prevent Failures

- Use pre-assembled cables9 from the factory whenever possible.

- Crimp with precision tools to ensure air-tight and water-tight seals.

- Avoid over-tightening, which can damage gaskets.

- Perform leak and pull tests during commissioning.

- Use UV- and salt-resistant cable ties to secure connections above waterline.

- Apply dielectric grease10 on metal contacts if allowed.

Well-installed waterproof connectors can last over 25 years even in harsh water environments.

Do Tier-1 Floating Solar Projects Use Specialized MC4 Solutions?

Yes, major floating solar projects use tested and approved MC4 variants from top-tier suppliers like Stäubli.

Floating solar installations from tier-1 EPCs and module brands use certified waterproof MC4 connectors11 — often MC4-Evo 212.

Case Studies from Real-World Projects

-

Sungrow Floating PV, China

Used Staubli MC4-Evo 2 with IP68 rating across 120MW of water-based solar.

-

Serendipity Lake Project, India

Used waterproof PV connectors with salt-spray tested cables and junction boxes.

-

EDF Energy’s Floating Farm, France

Employed Staubli marine-grade connectors and double-sealed glands on floats.

These projects demand consistent energy output and safety, and only proven MC4 types are used at scale.

Conclusion

Floating solar farms face unique environmental stresses that standard MC4 connectors cannot endure long-term.

-

Learning about UV radiation's effects on solar components is essential for ensuring longevity and performance in floating solar systems. ↩

-

Exploring the effects of corrosion on solar connectors can help in selecting durable materials for floating solar installations. ↩

-

Understanding MC4 connectors is crucial for optimizing solar energy systems, especially in challenging environments like floating solar projects. ↩

-

Understanding the impact of water on MC4 connectors is crucial for ensuring the longevity and safety of solar installations.

Explore this link for detailed insights. ↩ -

Learn how floating PV systems can mitigate connector issues to maintain efficiency and safety. This resource provides valuable strategies. ↩

-

Explore this link to understand the advantages of Marine-grade MC4 connectors for durability in harsh environments. ↩

-

Learn about IP68 ratings to see why they are crucial for waterproof applications, especially in marine settings. ↩

-

Explore this link to understand the importance of using marine-grade tools for reliable and long-lasting MC4 connector installations. ↩

-

Learn why using pre-assembled cables can significantly reduce installation errors and enhance the durability of your PV system. ↩

-

Discover how dielectric grease can improve the performance and longevity of your MC4 connectors in floating PV systems. ↩

-

Learn how waterproof MC4 connectors ensure durability and efficiency in challenging aquatic environments. ↩

-

Explore the advantages of MC4-Evo 2 connectors, which enhance reliability and performance in floating solar installations. ↩