What basic knowledge should I know before importing PV connectors from China?

I know many buyers feel confused when they try to import PV connectors from China because the market looks big, the prices are not stable, and the quality levels are very different.

You should know the basic standards, supplier types, production capability checks, and long-term performance factors before you place any order in China.

Many importers trust China because the country has strong manufacturing capacity, but it is still easy to make mistakes. I want to share what I have learned through real sourcing work so you can avoid the common risks and choose the right partner.

Which global standards do Chinese PV connectors follow?

Many buyers feel lost when they see different certifications on PV connectors, and they are not sure which one is real or necessary for their country.

Most high-quality PV connectors in China follow IEC 628521, UL 67032, or TÜV certification standards, but some low-end suppliers do not meet these rules, so you must check every document clearly.

Global Standards That Matter

Most PV connectors made in China follow international standards. Some suppliers focus on Europe, some focus on North America, and some try to cover both. These standards define insulation strength, waterproof levels, fire resistance, contact resistance, cable pull-out strength, and long-term durability.

Below is a simple table that shows the main certifications you will see when importing PV connectors from China:

| Standard | Region | Meaning |

|---|---|---|

| IEC 62852 | Global | Sets rules for PV connector safety, materials, and long-term performance |

| TÜV Certification3 | Europe | Confirms compliance with IEC and quality stability |

| UL 6703 | North America | Defines fire safety, insulation, and mechanical strength |

| IP67 / IP68 | Global | Waterproof and dustproof protection levels |

| RoHS4 | Global | Limits hazardous materials |

Why These Standards Matter

The standards help you understand how safe the connectors are. A connector that passes IEC or UL testing can handle long outdoor exposure, strong UV, high temperatures, and mechanical stress. These tests also confirm whether the connector can handle 1500V systems, which are common in utility solar farms.

Fake certifications are common in China. Some suppliers download sample reports from the internet, and some suppliers only test a few samples but do not run mass production under the same conditions. This is why checking the certificate number, the testing organization, expiration date, and traceability is very important.

How to Verify Certification Authenticity

I suggest you follow a simple method:

- Ask the supplier for the full TÜV or UL certificate in PDF format.

- Check if the model number on the certificate matches the real product.

- Visit the official TÜV or UL database to verify the certificate number.

- Ask for test reports, not only certificates.

- Confirm if the product and the cable are both certified, not just one part.

This simple process can prevent 80% of quality problems that happen after installation. Many PV connector failures come from uncertified products with weak insulation or unstable metal contacts. When you check the certificates carefully, you reduce this risk from the beginning.

What is the difference between manufacturers5 and traders6?

New buyers often think every supplier they meet is a “factory,” but this is not true. A lot of companies are traders or small workshops without real production capacity.

Manufacturers produce connectors with their own equipment, while traders only buy and resell products, so you need to know which type of supplier you are dealing with.

Why the Difference Matters

When you import PV connectors, the supplier type affects quality stability7, warranty reliability, delivery time, and the level of customization you can get. Real manufacturers have their own machines, testing labs, and engineers. Traders rely on partners, so control is weaker.

Here is a clear comparison:

| Item | Real Manufacturer | Trader / Reseller |

|---|---|---|

| Production control | Full | None |

| Quality consistency | High | Depends on supplier |

| Price stability | Strong | Weak |

| Customization | Easy | Limited |

| Warranty | More reliable | Uncertain |

| Risk level | Low | Higher |

How to Identify a Real Factory

I learned many tricks after working with Chinese suppliers for years. Some factories are open and honest, some are not. You can use simple methods to check:

1. Check business license and scope

A real manufacturer usually has “production,” “manufacturing,” or “industrial” in the business description. Traders often show “sales,” “trading,” or “commerce.”

2. Ask for production videos

A real factory can show injection molding machines, metal stamping lines, testing equipment, and assembly teams.

3. Request photos with date stamps

Factories can always provide real photos of machines and workers with current dates.

4. Ask how many molds they own

Manufacturers know every mold, part number, and tool. Traders do not.

5. Check if they own a testing lab

A real PV connector factory always has tools for pull-out tests, waterproof tests, insulation tests, and contact resistance tests.

These steps make it easier to filter good suppliers from unreliable ones.

How can I confirm whether a factory has real production capability?

Many buyers trust suppliers too quickly because the website looks professional, but websites cannot show the truth.

I confirm real production capability by checking equipment, testing processes, material sources, certifications, and production capacity reports.

What You Must Check in a Real Factory

A good PV connector factory must show several key abilities. These abilities prove that the supplier can produce connectors that meet global standards and stay stable for many years.

Below are the most important areas:

1. Mold development and ownership8

Real factories own their molds and update them regularly. If the supplier tells you they rent molds or rely on another factory, the risk is higher.

2. Injection molding quality9

A real factory controls molding temperature, pressure, and cooling time. This ensures the insulation material reaches the correct density and strength. Poor molding makes the connector crack under sunlight.

3. Metal contact production

The metal pins decide how much current the connector can handle. A good factory uses high-purity copper, silver plating, and stable stamping machines.

4. Material sourcing10

A reliable supplier never uses recycled plastic. High-quality connectors use PPO, PA66, or PC with UV resistance. If the material is low grade, the shell turns yellow or brittle after 2–3 years.

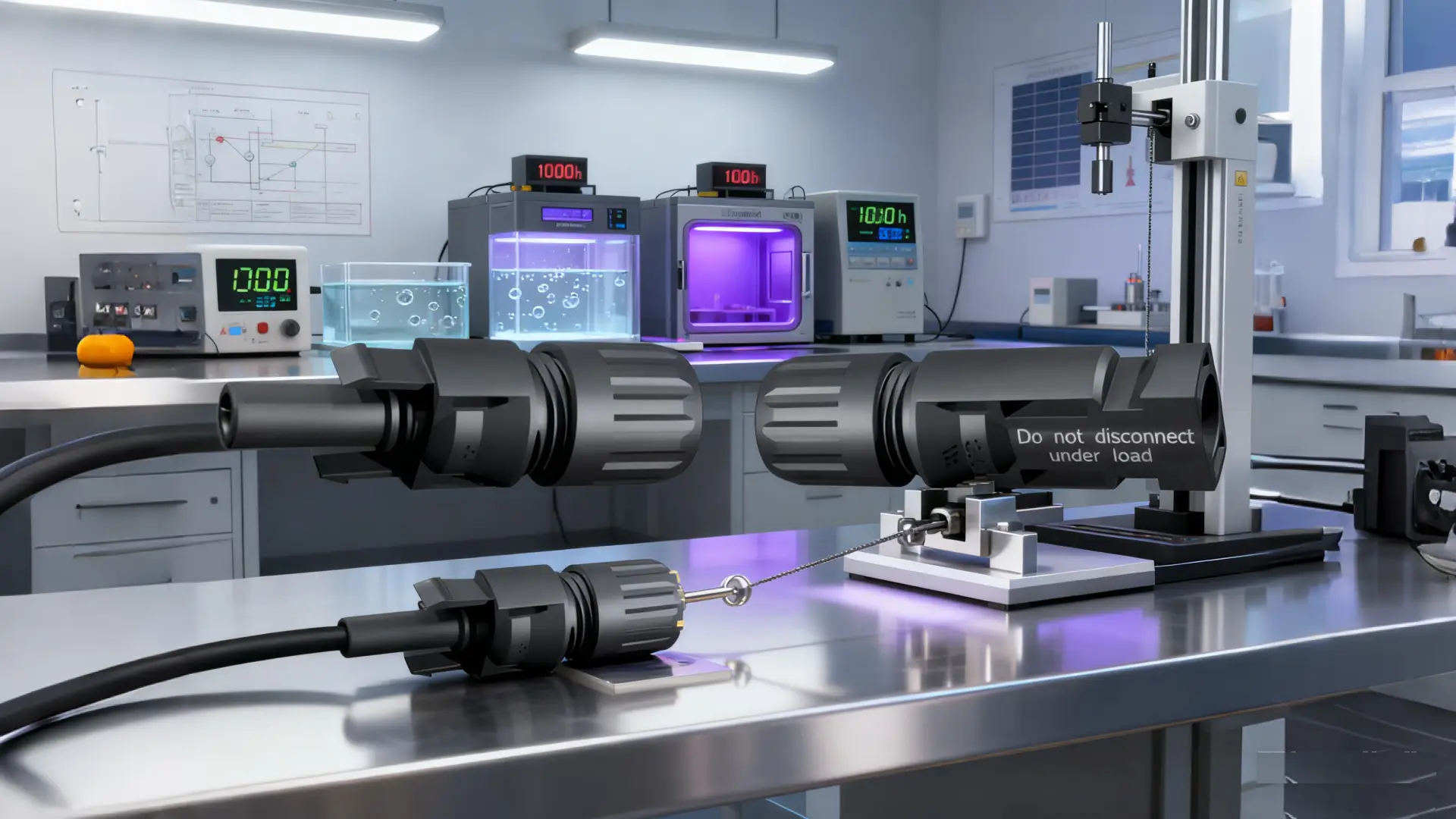

5. Quality testing11

Real factories run the following tests:

- IP67 / IP68 waterproof test

- Pull-out force test

- Contact resistance test

- Temperature rise test

- High-voltage insulation test

- Salt-spray corrosion test

- UV aging test

Suppliers that skip these tests cannot guarantee stability.

6. Production capacity

Some buyers order 50,000 sets and wait months because the supplier is too small. Always ask for monthly output data, production lead times, and backup plans.

Factory Capability Table

| Capability | What You Should Check | Why It Matters |

|---|---|---|

| Molds | Ownership, maintenance | Determines product accuracy |

| Materials | UV-resistant PPO/PA66 | Affects long-term durability |

| Metal pins | Pure copper, plating | Reduces overheating risk |

| Testing | Full test reports | Ensures compliance |

| Output capacity | Monthly data | Affects delivery reliability |

These steps protect you from suppliers who outsource everything and cannot guarantee quality.

Which factors affect the long-term lifespan of connectors?

Many buyers think the lifespan depends only on material quality, but lifespan actually comes from design, crimping, environment, and maintenance.

Long-term lifespan depends on material stability, metal contact quality, correct installation, and proper sealing against moisture and UV exposure.

Main Factors That Decide Lifespan

A PV connector stays outside for more than 25 years. Sunlight, wind, dust, humidity, and temperature changes all affect how long the connector lasts. Below are the most important factors:

1. Metal contact design12

The metal pin must keep stable resistance for 20+ years. If the pin is thin or soft, it causes heat. Many failures happen because the metal is too weak.

2. Crimping quality13

This is one of the biggest problems in real projects. Many connectors fail because installers use the wrong crimping tools. Poor crimping breaks the waterproof seal.

A system with good connectors but bad crimping still fails.

3. UV resistance14

The plastic shell must survive long UV exposure. If the plastic quality is low, it becomes brittle. When it cracks, water enters and creates electrical arcs.

4. Waterproof level15

You should choose connectors with IP67 or IP68. If the sealing ring is poor or installation is wrong, water enters and corrodes the metal.

5. Cable quality

A connector is safe only when paired with high-quality PV cable (H1Z2Z2-K). Poor cables cause overheating even if the connector is good.

6. Cross-mating risk

Mating connectors from different brands creates micro-gaps in the metal contacts. This leads to high resistance and fire risk. Many fires happen because installers mix brands.

Table: Factors Affecting Lifespan

| Factor | Impact |

|---|---|

| Metal contact | Controls heat and conductivity |

| Crimping | Affects stability and waterproofing |

| UV resistance | Controls shell aging speed |

| Waterproof level | Prevents corrosion |

| Cable quality | Supports current flow |

| Cross-mating | Creates overheating risk |

When you understand these factors, you will know how to select the right supplier and avoid long-term system problems.

Conclusion

You can import PV connectors safely when you understand standards, supplier types, factory ability, and long-term performance factors.

-

Understanding IEC 62852 is crucial for ensuring the safety and performance of PV connectors in solar applications. ↩

-

Learning about UL 6703 certification is essential for assessing fire safety and mechanical strength in PV connectors. ↩

-

Exploring TÜV Certification helps you ensure quality and compliance with European standards for PV connectors. ↩

-

Understanding RoHS compliance is vital for ensuring that PV connectors are free from hazardous materials. ↩

-

Understanding manufacturers helps you identify reliable suppliers and ensure product quality. ↩

-

Exploring traders' operations can help you navigate the complexities of sourcing products effectively. ↩

-

Quality stability is crucial for maintaining product standards and customer satisfaction. ↩

-

Understanding mold ownership helps ensure product quality and reduces risks associated with outsourcing. ↩

-

Exploring this topic reveals how critical molding processes are for ensuring long-lasting products. ↩

-

Learn why sourcing high-quality materials is essential for product performance and longevity. ↩

-

Discover the key tests that ensure product reliability and compliance with industry standards. ↩

-

Understanding metal contact design is crucial for ensuring long-lasting and reliable connections in electrical systems. ↩

-

Exploring crimping quality can help you avoid common installation mistakes that lead to connector failures. ↩

-

Learn about UV resistance to ensure your connectors can withstand harsh outdoor conditions without degrading. ↩

-

Discover the significance of waterproof levels to prevent corrosion and ensure the durability of your connectors. ↩