What basic knowledge do I need before importing genuine Staubli PV connectors from China?

Many importers rush into solar connector sourcing without enough preparation. They later discover issues with counterfeit parts, missing documents, or certification mismatches.

Before importing genuine Staubli PV connectors from China, you need to understand product authenticity, certification standards, import compliance, and supplier verification. These basics protect you from costly mistakes.

When I started helping clients source Staubli connectors, I realized how important these details were. A small error in connector specification or documentation can cause major losses. So, let’s go through what every importer should know before making their first shipment.

What should I learn about Staubli connector specifications before I start importing?

It’s easy to think all MC4 connectors are the same. But Staubli offers several connector types designed for specific voltage, current, and cable ranges.

You should understand Staubli connector series1, voltage ratings2, cable compatibility, and certifications before importing to ensure proper matching with your solar panels.

Dive deeper: Understanding Staubli connector types and ratings

Before importing Staubli PV connectors, I make sure to match every connector type with its exact technical use. The Staubli MC4 and MC4-Evo2 are two main families. The MC4 supports systems up to 1000V DC, while MC4-Evo2 supports up to 1500V DC. Choosing the wrong one may cause failure or void your warranty.

Here’s a simple comparison:

| Connector Type | Voltage Rating | Cable Cross-section | Typical Application |

|---|---|---|---|

| MC4 Original | Up to 1000 V DC | 4–6 mm² | Residential and commercial |

| MC4-Evo2 | Up to 1500 V DC | 6–10 mm² | Utility-scale and large PV arrays |

| MC4 Industrial | Up to 1500 V DC | 10 mm² | Harsh environments, floating systems |

You must also check the current rating. Staubli connectors are designed to carry 30–45A depending on the cable size and type. The cable insulation must meet H1Z2Z2-K or equivalent solar standards. Always confirm that both connector and cable share matching specifications.

Another key is genuine identification3. Real Staubli connectors have visible logos, serial codes, and batch numbers molded on the body. Counterfeits often miss these details or have subtle printing differences. When in doubt, cross-check the part number in Staubli’s official product catalog.

I also advise clients to study basic mechanical characteristics — like torque values, mating cycles, and IP ratings. Genuine Staubli connectors meet IEC 628524, UL 6703, and TÜV certifications. This means they are waterproof (IP67/IP68), UV-resistant, and tested for salt mist and temperature cycling.

Knowing these specifications gives you confidence in both sourcing and application.

How can I make sure my import process complies with Australian standards?

Many importers forget that Australia has its own compliance rules for electrical components. Non-compliance can delay customs clearance or block sales.

To comply with Australian standards, ensure your Staubli PV connectors meet AS/NZS electrical regulations5, carry valid certificates, and are imported with proper documentation.

When I handle shipments to Australia, I always start by identifying the HS code6 for Staubli PV connectors. It usually falls under “8536.69 – Electrical connectors for voltage not exceeding 1000 V.” Knowing this helps estimate duty rates and import taxes.

Then I verify that all product certifications meet Australian requirements. The AS/NZS 50337 standard specifies how DC connectors should perform under real-world conditions. Staubli’s certified connectors usually pass this test because they already comply with IEC 62852 and TÜV Rheinland standards.

Here’s what I include in every import file:

| Required Document | Purpose | Issued By |

|---|---|---|

| Certificate of Conformity8 (IEC/UL) | Product safety and performance | Staubli or TÜV |

| Test Report (UV, IP, contact resistance) | Technical validation | Independent lab |

| Certificate of Origin | Customs clearance | Exporter/Chamber of Commerce |

| Commercial Invoice + Packing List | Shipment details | Exporter |

| Bill of Lading / Air Waybill | Freight record | Carrier |

| Import Declaration | Compliance with Australian Border Force | Importer |

I also make sure that labeling is correct. Labels should show the part number, voltage rating, and country of origin (“Made in Switzerland” or “Made in China by Staubli Electrical Connectors”). Australian customs can reject shipments missing these details.

Partnering with a licensed customs broker helps. They manage tariffs, GST payments, and import declarations. I also recommend asking your supplier to include batch traceability documents — this makes warranty claims easier later.

What are the key risks I should know before importing from China?

China is a great place to source PV components, but it’s also where many counterfeit and “MC4-compatible” products appear.

The main risks are counterfeit connectors9, inconsistent quality10, and improper documentation11 during export or customs inspection.

Dive deeper: Avoiding counterfeit and quality issues

I’ve seen many importers lose money because they didn’t verify their suppliers. Some received connectors labeled “MC4-compatible” that weren’t made by Staubli at all. These look similar but lack proper contact technology, causing overheating and fire risks.

Here’s what I do to reduce these risks:

- Verify the supplier – Request their business license, export permit, and authorization letter from Staubli. Genuine distributors are usually listed on Staubli’s official website.

- Check part numbers – Staubli connectors have specific alphanumeric codes like “32.0016P0001-UR.” Fake ones often use partial or mismatched numbers.

- Inspect samples – Test physical samples before finalizing your bulk order. Confirm contact resistance and sealing performance.

- Use third-party inspection12 – Hire QC services like SGS or TÜV to perform pre-shipment checks. They verify packaging, labeling, and batch numbers.

- Request official datasheets and test reports – Always keep these as your product’s compliance proof.

If you find a price that seems “too low,” it’s often a red flag. Staubli products maintain a consistent market price due to their precision manufacturing. Discounts beyond 25% from global average rates usually indicate counterfeit or rejected stock.

Also, note that mixing connectors from different manufacturers on one PV string is unsafe. Cross-mating Staubli with non-Staubli connectors can lead to contact mismatch and heat buildup. Always use original pairs from the same brand.

How can I prepare my business to import Staubli PV connectors safely?

Importing Staubli connectors safely is about preparation. Without proper systems, even genuine goods can face customs or quality problems.

To import Staubli PV connectors safely, set up a supplier verification system13, import documentation plan14, and post-shipment quality control process15.

Dive deeper: Building a reliable import process

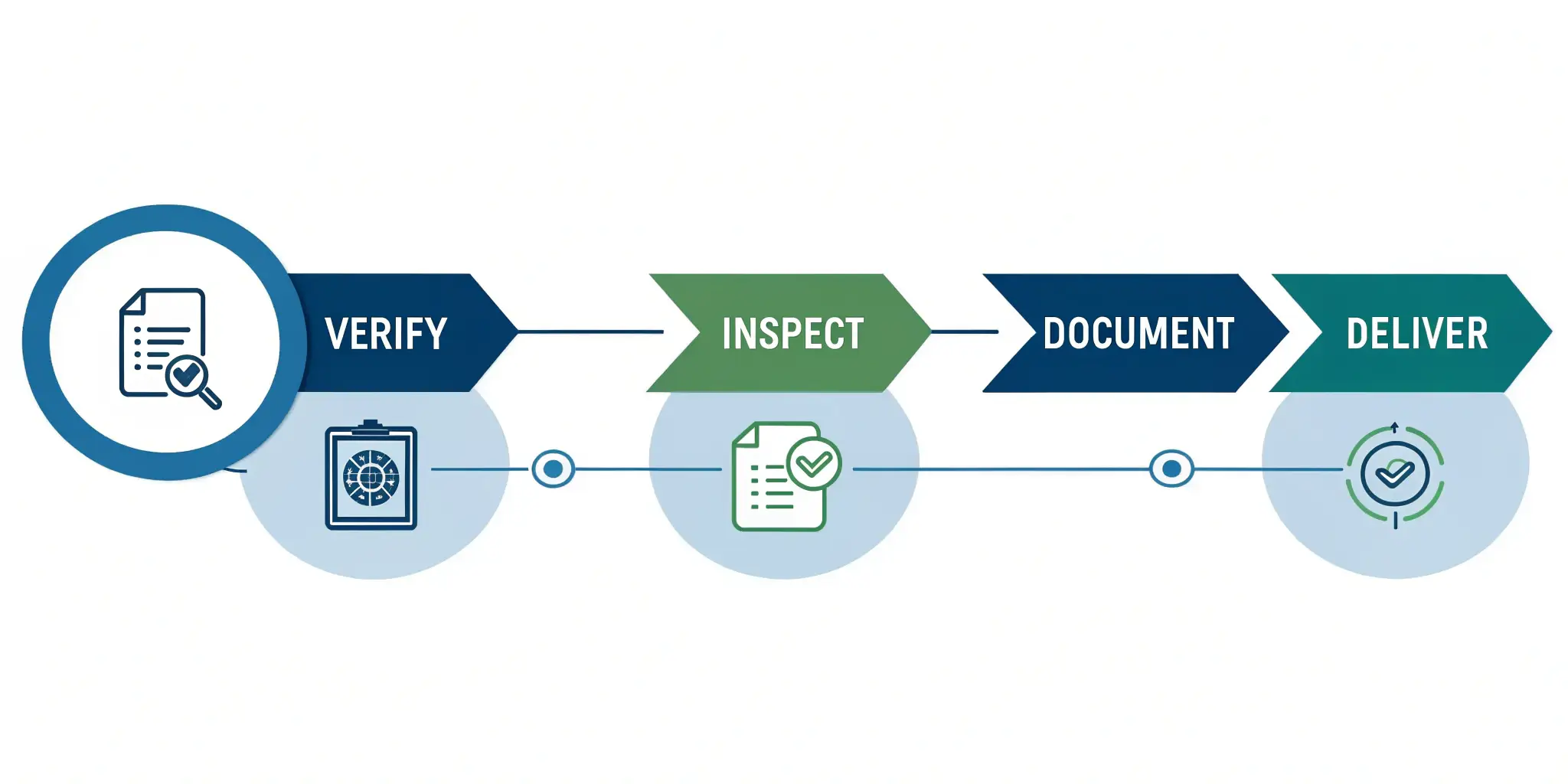

I always advise new importers to treat connector sourcing like any technical project — plan, verify, and document everything. Here’s the workflow I use:

| Step | Action | Description |

|---|---|---|

| 1 | Define requirements | Voltage, current, cable size, connector model |

| 2 | Shortlist suppliers | Use official Staubli distributor list or verified B2B platforms |

| 3 | Verify authenticity | Request authorization letters, test reports, and business license |

| 4 | Order samples | Test for fit, sealing, and electrical contact |

| 5 | Finalize contract | Use clear Incoterms (FOB/CIF/DAP) and include warranty clauses |

| 6 | Pre-shipment inspection | Hire SGS or TÜV for verification |

| 7 | Manage shipping | Choose insured logistics and track customs documents |

| 8 | Conduct incoming inspection | Check labeling, packaging, and serial numbers |

| 9 | Store records | Keep all certificates, invoices, and photos for traceability |

Having this system reduces uncertainty. You can also assign responsibility to a procurement manager or import agent who tracks supplier communication and logistics milestones.

For example, I once helped an Australian factory import MC4-Evo2 connectors. The client almost bought from a reseller who didn’t have TÜV certificates. We verified the supplier’s license, found missing batch documents, and avoided a $20,000 mistake. That experience proved how vital documentation is in this process.

You can also set up a “compliance folder” for each shipment — include invoices, certificates, inspection photos, and tracking records. This simple habit builds long-term credibility with customs, banks, and clients.

Conclusion

Before importing Staubli PV connectors, learn the product details, confirm compliance, verify suppliers, and document every step for safe and successful trade.

-

Understanding the various Staubli connector series is crucial for ensuring compatibility with your solar panels. ↩

-

Knowing the voltage ratings helps you select the right connector for your solar system, preventing potential failures. ↩

-

Learning how to identify genuine connectors protects you from counterfeits that could compromise your installation. ↩

-

Exploring IEC 62852 certification ensures that the connectors meet safety and performance standards for solar applications. ↩

-

Understanding AS/NZS regulations is crucial for compliance and avoiding delays in customs clearance. ↩

-

Knowing the correct HS code helps in estimating duty rates and ensuring smooth customs processing. ↩

-

Exploring the AS/NZS 5033 standard will help you ensure your products meet performance requirements. ↩

-

A Certificate of Conformity is essential for proving product safety and compliance with Australian standards. ↩

-

Understanding the risks of counterfeit connectors can help you avoid costly mistakes and ensure product safety. ↩

-

Learn strategies to maintain quality control and avoid issues that can arise from inconsistent product quality. ↩

-

Proper documentation is crucial for smooth customs clearance and avoiding legal issues during import. ↩

-

Third-party inspections can provide peace of mind and ensure that your products meet quality standards before shipment. ↩

-

Understanding supplier verification systems is crucial for ensuring the authenticity and quality of imported goods. ↩

-

A comprehensive import documentation plan is essential for smooth customs clearance and avoiding delays. ↩

-

Exploring post-shipment quality control processes can help maintain product standards and customer satisfaction. ↩