Can U-Shaped and O-Shaped Contacts Be Used Interchangeably in Solar PV Systems?

The wrong choice of MC4 contact pin type can turn a solar installation into a long-term headache.

No, U-shaped and O-shaped contacts should not be used interchangeably—they have different compatibility, crimping, and safety requirements.

Mixing U- and O-type pins might seem harmless. But without understanding their structural, mechanical, and compliance differences, the risk of failure and voided warranty is real. Let’s break down the facts.

Are U-shaped and O-shaped MC4 contacts compatible with the same connector housings?

Using the same connector housing for different pin shapes is a tempting shortcut—but not a safe one.

U-shaped and O-shaped MC4 pins1 may fit in the same housing model, but that doesn’t mean they’re fully compatible in performance or safety.

Why the Housing Fit Isn’t Enough

Even though Staubli and other MC4 manufacturers design housings that can physically accept both pin shapes, that’s not the whole story. Mechanical alignment, contact pressure2, and locking retention vary depending on the shape of the pin. These factors affect how current flows and how heat is dissipated.

| Feature | U-Shaped Pin | O-Shaped Pin |

|---|---|---|

| Housing Fit | Often compatible | Often compatible |

| Contact Pressure | Less uniform | Highly uniform due to round shape |

| Risk of Disconnection | Higher in vibration environments | Lower due to snug fit |

| Resistance to Moisture | Standard | Better sealing geometry |

Even slight misalignment in how the pin mates inside the housing can create higher contact resistance or introduce mechanical stress. Over time, this may lead to disconnection or overheating, especially under load.

Why Some Installers Still Try

Some field installers try to use whatever pin is on hand, especially for urgent repairs or low-budget jobs. But forcing an O-pin into a U-pin housing or vice versa is like forcing a key into the wrong lock. It might turn, but it wears everything out.

What are the risks of mixing U-type and O-type pins in the same PV string?

The type of pin you use affects more than the connector—it impacts the entire PV string’s performance.

Mixing U-type and O-type pins introduces uneven current flow3, potential hotspots, and increases the risk of long-term mechanical failure4.

What Happens When You Mix Pin Types

When you mix contact types within the same string or array, especially in high-current settings, the system can become unstable. You may face:

- Uneven power loss at connection points

- Inconsistent clamping forces

- Accelerated wear at different contact sites

- Increased electrical noise

A Real-World Example

In one 50kW rooftop project, a contractor used U-pins in half the connectors and O-pins in the rest—just to finish the job on time. Within 18 months, IR scans showed multiple hotspots. Disassembly revealed loose crimping on the U-pins, and stress marks on the O-pins from forced fitting.

They had to replace over 70% of the connectors.

| Risk | Impact |

|---|---|

| Uneven Contact Resistance | Causes heat buildup |

| Mechanical Mismatch | Leads to loosening or cracking |

| Non-uniform Performance | Reduces string output efficiency |

| Inspection & Testing Failure | May trigger IEC/TÜV compliance issues |

Even though the connectors “worked” short-term, the performance penalty and maintenance costs were severe.

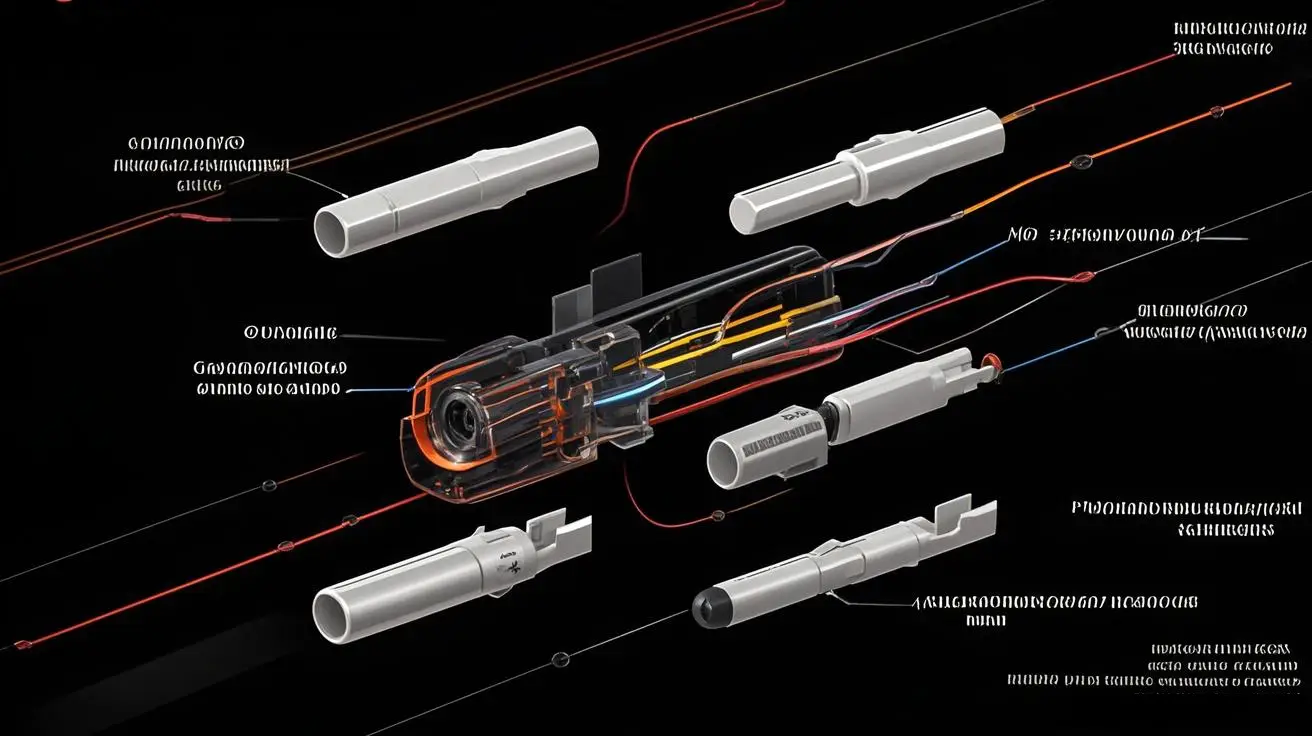

Can standard MC4 crimping tools5 handle both U and O contact shapes reliably?

Crimping is the foundation of a good electrical connection. And pin shape makes a big difference.

No—most standard MC4 crimping tools are optimized for one pin shape, not both. Using the wrong die risks a weak or non-compliant crimp.

The Problem with One-Size-Fits-All Tools

Most solar electricians carry a “universal” MC4 crimper. It works well with standard U-pins. But O-pins, especially machined types, require deeper and more concentric crimping force. Some high-quality tools offer interchangeable dies or adjustable pressure—but that’s not standard.

| Crimp Tool Type | Works with U-Pins | Works with O-Pins | Risk Level |

|---|---|---|---|

| Budget Manual Crimper | ✅ | ❌ | High |

| Professional Crimper + Dies | ✅ | ✅ | Low |

| Automatic Pneumatic Crimper | ✅ | ✅ | Very Low |

Improper Crimp = Long-Term Trouble

An improperly crimped pin will slowly loosen under temperature cycles. That creates micro-arcs, heat buildup, and can eventually melt the connector.

I’ve seen projects where crimping inconsistency caused system derating by over 15% in just two years. It’s not worth the shortcut.

Does switching pin types affect TÜV or IEC compliance6 in solar installations?

This is where it gets serious. Regulatory bodies like TÜV and IEC don’t just test individual parts—they certify systems based on known combinations.

Yes—switching pin types can void compliance if the specific connector model was not tested and approved with that pin variant.

Certification Is Combination-Specific

A Staubli MC4 connector7 with an O-pin might carry TÜV certification. But the same housing with a stamped U-pin may not. If an installer swaps them without checking datasheets or manufacturer guidance, they’ve unknowingly voided certification.

| Certification Body | Connector Housing | Approved Pin Type |

|---|---|---|

| TÜV Rheinland | MC4-Evo2 | O-shaped only |

| IEC 62852 | MC4 Standard | U or O (depends on model) |

Insurance and Warranty Implications

A non-compliant part in a certified system can lead to:

- Denied warranty claims from panel makers

- Insurance refusal after fire or failure

- Legal liability for installers

No one wants to explain to a customer—or a lawyer—why they swapped connector pins without verifying compliance.

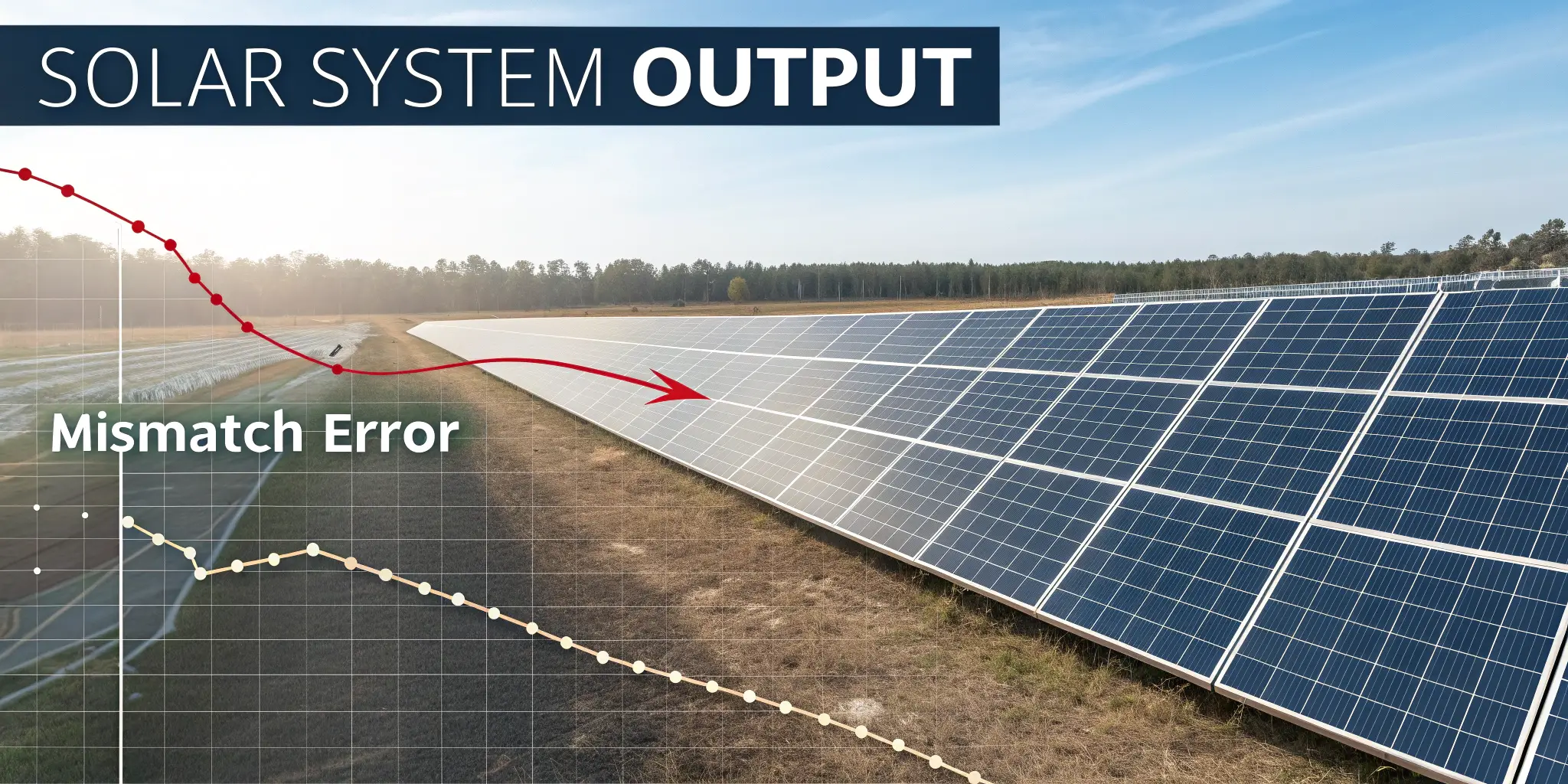

How does using mismatched contacts impact long-term performance and warranty?

Using mixed or incorrect pin types might not show problems today—but the impact builds silently.

Mismatched or incompatible contacts can reduce efficiency, increase maintenance costs, and potentially void system warranties8.

Performance Drop-Offs Over Time

- Higher contact resistance9 causes energy loss

- More frequent cleaning and retightening required

- Failure points become harder to detect without thermal scanning

Even Tier-1 solar modules like LONGi or Jinko may reject warranty claims if connector damage stems from using mismatched contacts.

| Symptom | Likely Cause |

|---|---|

| Decreased Output | Contact resistance buildup |

| IR Hotspot Detection | Poor crimp or mismatched geometry |

| Connector Body Cracking | Mechanical stress from wrong fit |

| Intermittent Disconnections | Loose or unapproved pin use |

In one project, we had to send replacement MC4s to a customer who mixed pin types—after six failed junction boxes within three years. That was a learning moment for both of us.

Conclusion

Mixing U- and O-pins in solar connectors creates silent risks—lower performance, voided warranties, and potential system failures down the line.

-

Understanding the compatibility of U-shaped and O-shaped MC4 pins is crucial for ensuring safety and performance in electrical connections. Explore this link for detailed insights. ↩

-

Contact pressure is vital for reliable electrical connections. Learn more about its significance and how it affects performance in MC4 connectors. ↩

-

Understanding uneven current flow can help you prevent performance issues in solar installations. ↩

-

Exploring the causes of mechanical failure can guide you in choosing the right connectors for durability. ↩

-

Explore this link to find the best MC4 crimping tools that ensure reliable connections for both U and O contact shapes. ↩

-

IEC compliance is vital for solar systems. Learn more about its impact on safety and performance by checking this resource. ↩

-

MC4 connectors are essential for solar systems. Discover their role and compliance requirements to ensure your installation is safe and effective. ↩

-

Explore how using the wrong contacts can lead to warranty issues and financial losses. ↩

-

Learn how contact resistance impacts energy efficiency and maintenance costs in solar systems. ↩