What’s the Difference Between MC4 and MC4-Evo Connectors in Solar Applications?

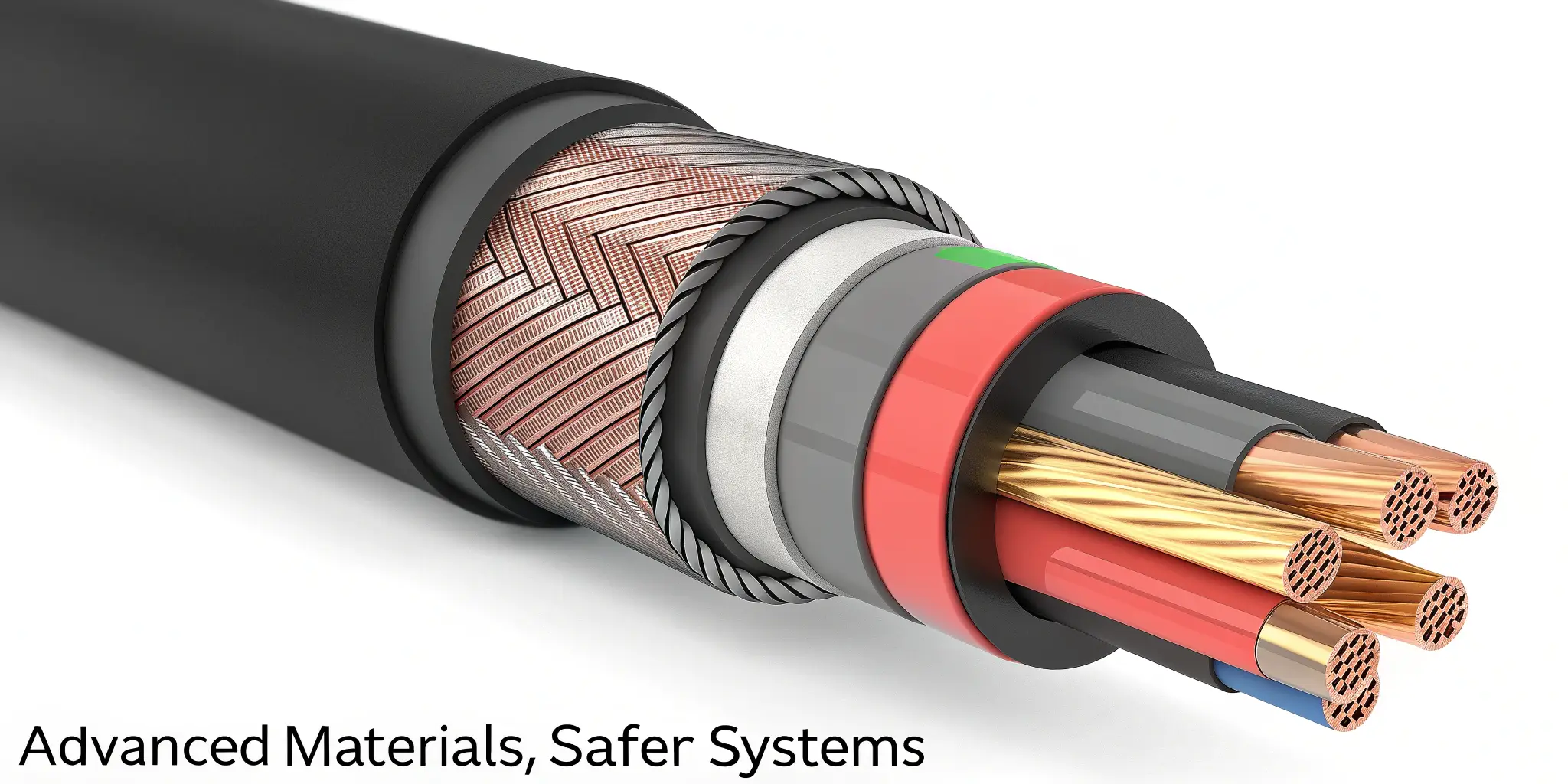

Solar panel connectors may look similar on the outside, but what’s inside makes all the difference when it comes to safety and performance.

MC4-Evo 2 connectors are more advanced and durable than traditional MC4s, especially for high-voltage, long-term installations.

If you're in the solar business like I am, understanding connector differences isn’t just technical—it’s practical. Whether you’re working on residential rooftops or utility-scale farms, connector failure is something you can't afford. So let’s break it down clearly.

Is MC4-Evo Backward Compatible with Traditional MC4 Connectors?

Solar projects often mix old and new parts. So compatibility matters.

Yes, MC4-Evo 21 is backward compatible2 with standard MC4 connectors3, but you must follow specific assembly rules.

How Backward Compatibility Works

- Locking System: MC4-Evo 2 retains the same push-lock system used in traditional MC4 connectors.

- Contact Pins: The Evo 2 contact pins still fit the standard crimping tools, with matched dimensions.

- Voltage Tolerance: Evo 2 can handle up to 1500V, so pairing it with 1000V MC4s won’t damage the system—but it limits performance to the lower spec.

| Feature | MC4 | MC4-Evo 2 |

|---|---|---|

| Max Voltage | 1000V | 1500V |

| Waterproof Rating | IP67 | IP68 |

| Contact Material | Tin-plated Cu | Silver-plated Cu |

| Crimp Compatibility | Standard | Standard |

| UL/IEC Certification | Yes | Yes |

Stick to manufacturer guidance. Not all combinations are certified under safety standards. So while you can connect MC4 to MC4-Evo, you should do it carefully and only when approved.

Does MC4-Evo Reduce Fire Risks Compared to Standard MC4?

Safety is a serious concern in solar installations. A bad connector can literally start a fire.

Yes, MC4-Evo 2 reduces fire risks due to better contact stability and stronger material insulation.

Why MC4-Evo Is Safer

- High-Temperature Resistance4: Its housing is made from enhanced plastic (PPO) with better UV and heat resistance.

- Silver-Plated Contacts: This improves conductivity and reduces overheating caused by resistance.

- Snap-In Locking System5: Prevents loose connections over time, one of the main causes of fires.

A lot of the fire incidents I've seen in failed PV systems had to do with connectors loosening under sun exposure. MC4-Evo 2 resists that heat cycle expansion-contraction effect better.

Why Do Some Tier-1 Solar Panel Brands Choose MC4-Evo 2?

Brands like Trina and LONGi don’t take risks on components that can compromise their panels.

Tier-1 brands6 choose MC4-Evo 2 for its certification7, durability, and long-term reliability in harsh environments.

Tier-1 Brand Priorities

- Certification: Evo 2 meets global safety standards, including TÜV and UL.

- Weatherproofing: Used in markets like Australia and the Middle East with extreme heat.

- Efficiency Preservation: Lower resistance in Evo 2 means better energy transfer over the system’s lifetime.

Brands like JinkoSolar and Canadian Solar offer modules pre-installed with MC4-Evo 2 connectors for their premium products, especially in utility-scale projects.

What Are the Key Technical Differences Between MC4 and MC4-Evo 2?

Let’s go beyond marketing and dig into the specs that matter when you’re on-site or designing a system.

MC4-Evo 2 has higher voltage ratings8, better sealing9, and improved thermal stability10 compared to the standard MC4.

Specification Breakdown

| Feature | MC4 | MC4-Evo 2 |

|---|---|---|

| Max Voltage | 1000V | 1500V |

| Current Rating | 30A | 39A |

| Protection Class | IP67 | IP68 (submersible) |

| Material (Housing) | PA/PC Blend | PPO |

| Flammability Class | UL94-V0 | UL94-V0 |

| Certification | IEC, UL | IEC, UL |

Evo 2 is engineered for demanding installations. If you’re designing systems that must operate 25+ years under full sun, hail, and wind—Evo 2 is the safer bet.

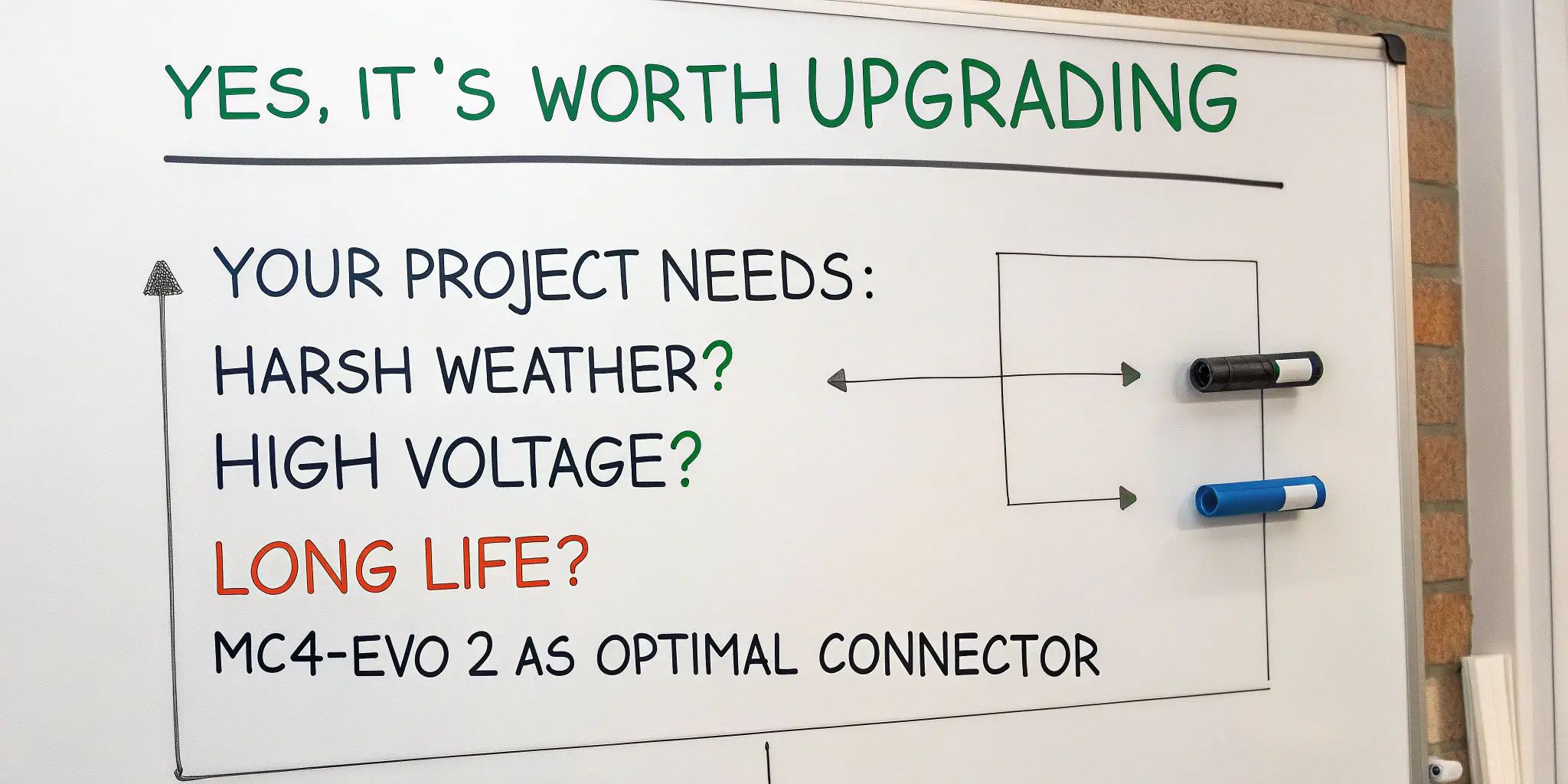

Is It Worth Upgrading from Standard MC4 to MC4-Evo 2?

Upgrades aren’t free, but neither is system failure.

Yes, it’s worth upgrading to MC4-Evo 2 if your solar project needs to meet high durability and safety standards11.

When the Upgrade Pays Off

- Utility-Scale Projects: Fire safety, long cable runs, and high-voltage DC systems benefit most.

- Harsh Weather Conditions: High UV zones, coastal salt air, and industrial settings.

- Regulatory Compliance: If your jurisdiction requires IP68 or 1500V compliance.

For small rooftop projects, the added cost might not be justified. But for anything beyond 10kW or installed in tough environments, Evo 2 gives peace of mind.

Conclusion

MC4-Evo 2 connectors bring more safety, higher efficiency, and longer durability—worth it for future-proofing any serious solar installation.

-

Explore this link to understand the compatibility features and benefits of the MC4-Evo 2 connector system for your solar projects. ↩

-

Learn more about backward compatibility in solar connectors to ensure your installations are safe and efficient. ↩

-

Discover the importance of MC4 connectors in solar energy systems and how they enhance performance and safety. ↩

-

Learn about the importance of high-temperature resistance in solar connectors and its role in preventing fire hazards. ↩

-

Discover how the Snap-In Locking System enhances connection stability and safety in solar installations, reducing fire risks. ↩

-

Learn about the criteria that classify Tier-1 solar brands and why they prioritize quality components like MC4-Evo 2. ↩

-

Discover essential certifications for solar components to ensure safety and performance, crucial for long-term investments. ↩

-

Understanding the benefits of higher voltage ratings can help you choose the right solar connectors for your projects. ↩

-

Learning about sealing benefits can guide you in selecting connectors that withstand harsh environments. ↩

-

Exploring thermal stability can enhance your knowledge of connector reliability in extreme conditions. ↩

-

Learn about the significance of durability and safety standards in solar energy systems to ensure long-term performance. ↩