Why Applying No-Oxide Grease Can Double Your MC4 Connector Lifespan?

It’s frustrating to see solar connectors degrade early—especially when you're working hard to build reliable systems.

Applying no-oxide grease helps prevent corrosion, arcing, and contact resistance, ultimately doubling the operational lifespan of MC4 connectors in harsh outdoor conditions.

MC4 connectors are known for durability, but like anything exposed to sun, rain, and air—they degrade. Here's how a small tweak like applying the right grease can have a big impact.

What Is No-Oxide Grease and How Does It Protect MC4 Connectors?

When you see a failed solar connector, there’s a good chance it started with corrosion.

No-oxide grease1 forms a protective barrier over MC4 contacts2, shielding them from moisture, air, and conductive contaminants that cause oxidation and overheating.

Dive Deeper: How No-Ox Works

No-oxide grease—sometimes called antioxidant grease—is specially made to block oxygen and moisture from reaching metal contacts. Here's what it does:

- Fills micro gaps between metals

- Prevents oxygen ingress

- Displaces water and dust

- Minimizes contact resistance

| Feature | No-Ox Grease | No Grease |

|---|---|---|

| Oxidation Protection | ✅ Excellent | ❌ None |

| Arcing Resistance | ✅ Yes | ❌ No |

| Contact Longevity | ✅ Doubled lifespan | ❌ Shortened |

| Application Ease | ✅ Simple | ✅ Simple |

This protective layer is key in outdoor systems exposed to temperature shifts, salty air, and dust storms.

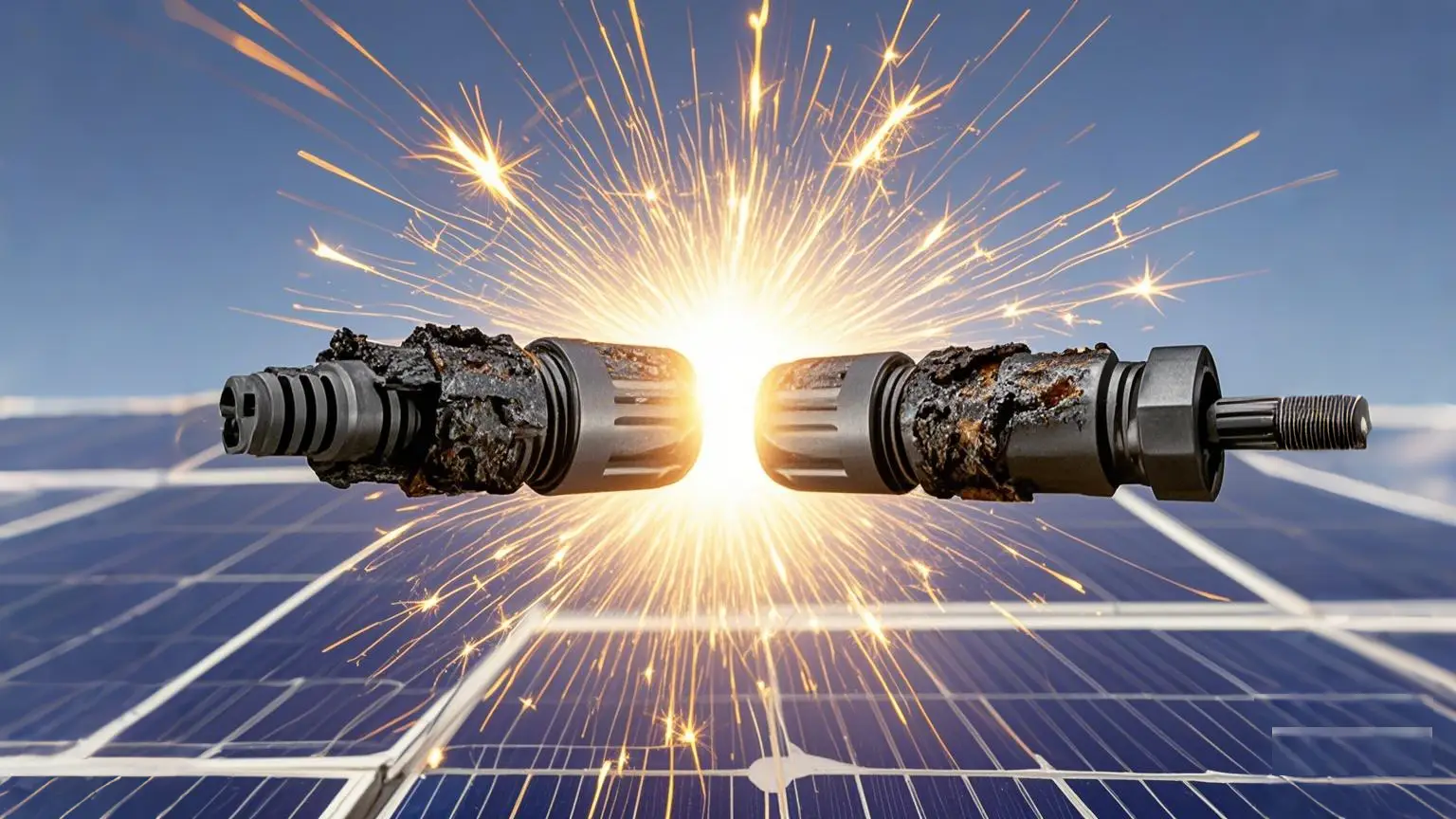

Why Does Oxidation Ruin MC4 Connectors Over Time?

Even if your MC4 connectors3 are IP-rated, they’re not invincible.

Oxidation corrodes the contact surfaces4 inside MC4 connectors, creating resistance, heat buildup, and eventual power failure.

Dive Deeper: What Happens Without Protection

Over time, air and moisture sneak into MC4 housings. Inside:

- Copper contacts begin oxidizing

- Resistance increases

- Efficiency drops

- Heat builds up at contact points

- Plastic casings may deform or catch fire

The scary part? These issues usually begin invisibly. By the time you notice them—your power yield may already have dropped significantly.

Is Dielectric or No-Oxide Grease Better for Solar Connectors?

You’ve probably heard both terms—but they’re not the same thing.

For MC4 connectors, no-oxide grease is preferred over dielectric grease5 because it actively prevents corrosion, not just insulates.

Dive Deeper: Comparing the Two Greases

| Property | Dielectric Grease | No-Oxide Grease |

|---|---|---|

| Moisture Barrier | ✅ Good | ✅ Excellent |

| Conductivity | ❌ Non-conductive | ✅ Conductive |

| Corrosion Prevention | ❌ Passive | ✅ Active |

| Best Use Case | Spark plug boots, auto fuses | Solar PV connectors, terminals |

Dielectric grease is non-conductive—it’s great where you want electrical isolation. No-oxide grease is conductive and corrosion-resistant, ideal for tight electrical connections like MC4 terminals.

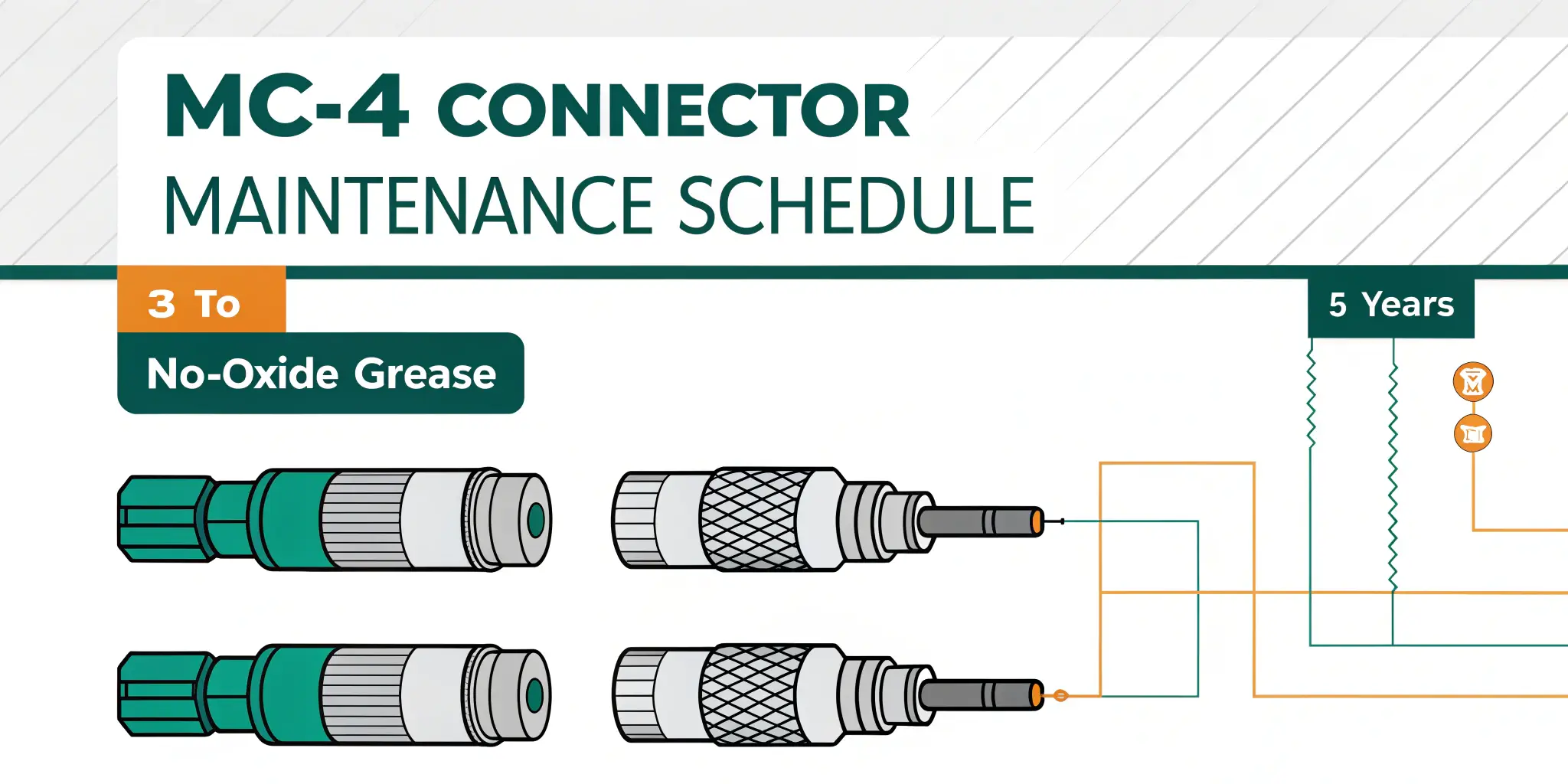

How Often Should You Reapply Grease to MC4 Connectors in Outdoor Systems?

Grease isn’t permanent, especially in extreme conditions.

Reapplying no-oxide grease every 3 to 5 years helps maintain maximum protection, especially in high-UV, humid, or coastal areas.

Dive Deeper: Maintenance Schedules by Environment

| Environment | Reapplication Frequency |

|---|---|

| Desert (UV + Dust) | Every 3 years |

| Coastal (Salt Air) | Every 2–3 years |

| Temperate Inland | Every 5 years |

| Snowy/Mountainous | Every 4 years |

Tip: Reapply whenever you do annual inspections, especially if you’re opening and reseating connectors.

Can No-Oxide Grease Prevent Arcing and Fire in Solar Installations?

Yes—and that’s where it earns its value.

By reducing oxidation and ensuring a clean, conductive connection, no-oxide grease drastically lowers the chances of arcing, overheating, and fire in MC4 connector junctions.

Dive Deeper: The Fire Prevention Argument

Most PV connector fires start from these issues:

- Loose crimps

- Corroded contacts

- Moisture ingress

- Thermal cycling

No-oxide grease:

- Maintains low resistance at the junction

- Prevents micro gaps from oxidizing

- Keeps connection temperature within safe limits

- Enhances long-term electrical continuity

This is why some Tier-1 EPCs and solar farms now mandate the use of grease during MC4 installation—especially in high-voltage or off-grid setups.

Conclusion

Using no-oxide grease is a simple habit that doubles connector life and lowers the risk of fires—making every solar installation safer and more efficient.

-

Explore this link to understand the science behind No-oxide grease and its benefits for solar connectors. ↩

-

Learn about MC4 contacts to see how they function in solar systems and why protection is crucial. ↩

-

Learn about MC4 connectors to understand their role in solar energy systems and how to maintain them effectively. ↩

-

Understanding how oxidation affects MC4 connectors can help you prevent power failures and ensure efficiency. ↩

-

Learn about dielectric grease's applications and benefits, particularly in electrical isolation, to understand its role in various settings. ↩