O-Pin vs U-Pin in Solar Connectors: Why Tier-1 Brands (Trina, LONGi) Prefer O-Pin

Tier-1 solar brands don’t make decisions lightly. The pin shape inside a solar connector may seem small, but it makes a big difference in reliability and performance. So, which do they trust more—O-pin or U-pin?

Most Tier-1 solar panel manufacturers now prefer O-pins in their MC4 connectors due to better durability, conductivity, and long-term field performance.

Let me explain why the big brands are shifting. We’ll look at how O-pins compare with U-pins in the real world—and why this choice matters in high-value solar projects.

Which Pin Type—O or U—Do Brands Like Trina and LONGi Use by Default?

Trina and LONGi, two of the world’s leading Tier-1 solar panel brands, have transitioned toward connectors compatible with machined O-pins1. Trina, for example, moved to TS4 connectors2, which allow better contact performance. Many of these connectors are Staubli-compatible3 and feature solid machined contacts—O-shaped.

Why this matters: This isn’t just a branding change. It reflects real operational priorities. These manufacturers are under pressure to deliver long-term field reliability, meet international safety standards, and reduce warranty claims.

Dive deeper: What’s behind this shift?

| Brand | Connector Standard | Default Pin Type | Notable Change |

|---|---|---|---|

| Trina Solar | TS4 (Staubli-compatible) | O-pin | Shifted from MC4/UTX |

| LONGi Solar | MC4-Evo 2 / TS4 | O-pin | Focus on TÜV + heat |

Both companies emphasize low resistance, longer life, and stronger mechanical bonding. O-pins help them meet these targets better than stamped U-pins.

Why Do Most Tier-1 Manufacturers Favor O-Pin Over U-Pin in MC4 Connectors?

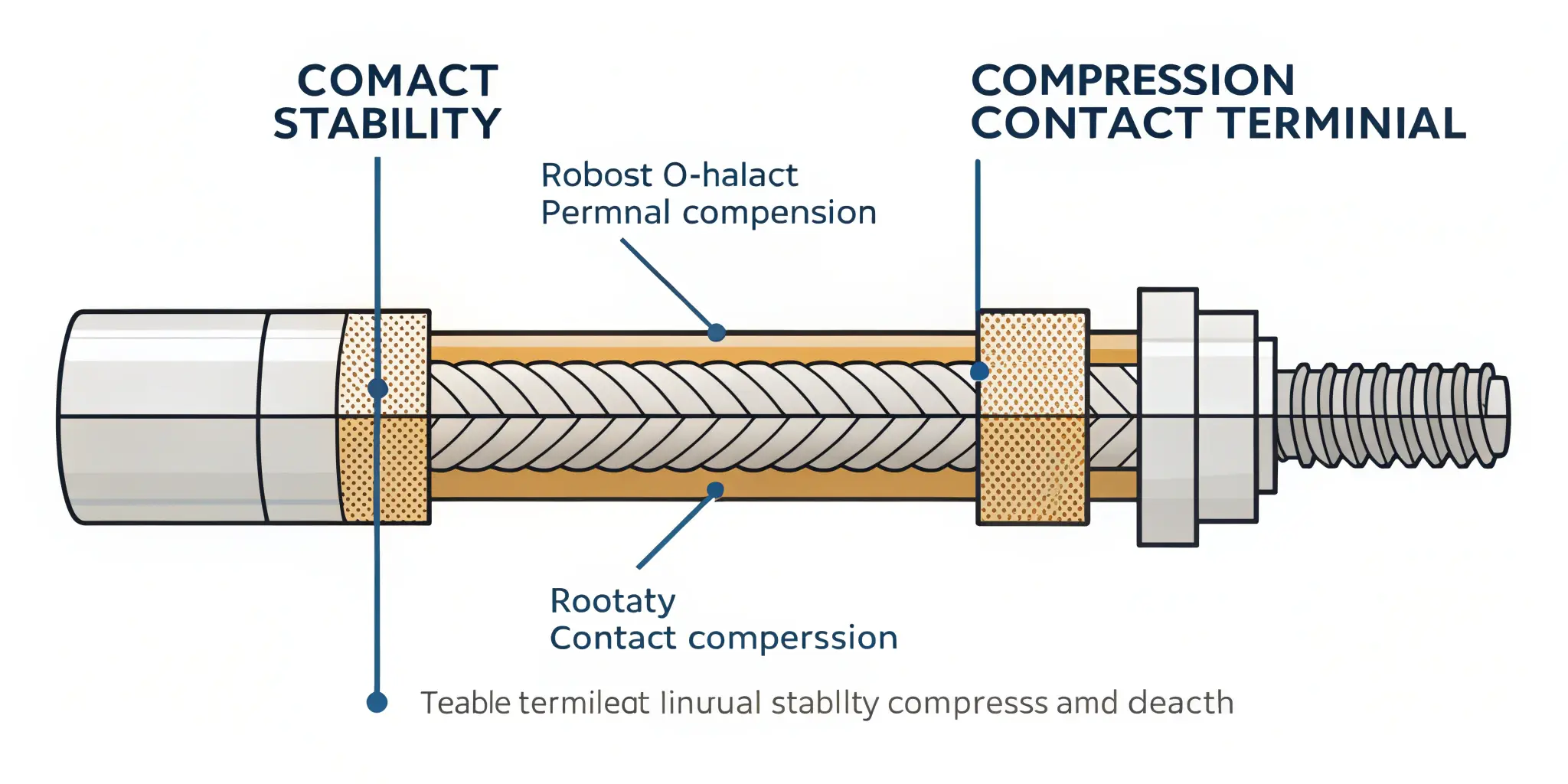

It comes down to performance. O-pins are machined from solid metal. U-pins are stamped and bent from thin metal sheets. This simple manufacturing difference leads to major field outcomes.

O-pins are stronger, more stable, and deliver lower contact resistance over time.4

Here’s what manufacturers like Trina, LONGi, and JinkoSolar are prioritizing:

- Stronger mechanical grip5: O-pins hold contact tension longer. This means fewer thermal disconnects.

- Lower electrical resistance6: More contact points = less heat = more stable current.

- Better corrosion resistance: O-pins have less exposed surface area for moisture or salt to attack.

- Fewer connector recalls or warranty claims: Less risk = lower cost.

In a 25-year installation, these small differences matter a lot.

Are U-Pin Contacts More Prone to Field Failures in Utility-Scale Solar?

Yes. U-pin contacts7—being stamped and thinner—are more likely to deform under high current or heat. I’ve seen it in practice. When installers crimp U-pins improperly, the risks skyrocket.

Deformed or loose U-pins can cause hot spots, voltage drops, and even fire hazards8.

[^9], dramatic flare, smok](https://rayenrg.com/wp-content/uploads/2025/05/Crimped-MC4-connector-failures-in-field.webp)

Here’s what goes wrong in real-world conditions:

- Vibration loosens weak crimps

- Thermal expansion breaks weak contact tension

- High current heats up the small contact area

- Moisture sneaks into gaps and causes corrosion

Let’s compare:

| Failure Mode | U-Pin Risk | O-Pin Risk |

|---|---|---|

| Crimp loosening | High | Low |

| Heat build-up | Medium | Low |

| Corrosion in contact area | High | Low |

| Mechanical deformation | High | Low |

| Fire due to arc formation | Medium | Very Low |

That’s why many EPCs and project developers now specify O-pin-compatible connectors for utility-scale plants.

How Does O-Pin Design Lower Maintenance Costs for Large-Scale PV Systems?

O-pins help lower both short-term troubleshooting and long-term maintenance budgets.

With fewer connection failures, O-pins reduce inspection frequency9 and repair events.

Here’s how this plays out in cost:

- Lower downtime: Fewer loose connectors or hot spots = more uptime.

- Lower labor cost: Less connector replacement or re-crimping.

- Longer intervals between checks: More confidence in long-term stability.

- Less thermal degradation: O-pins resist aging in desert or coastal weather.

In large systems where thousands of connectors are used, even a 1% failure rate can lead to huge service costs. O-pins keep those numbers down.

Conclusion

Most Tier-1 manufacturers like Trina and LONGi now prefer O-pins in their MC4 connectors. O-pins offer stronger contact force, better heat resistance, and more reliable long-term performance—especially in harsh environments or utility-scale setups.

-

Understanding O-pins can help you grasp their advantages in solar technology, enhancing your knowledge of solar panel efficiency. ↩

-

Exploring TS4 connectors will provide insights into their benefits and how they improve solar panel performance and reliability. ↩

-

Learning about Staubli compatibility can help you understand the standards in solar technology and their impact on installation and maintenance. ↩

-

Explore the benefits of O-pins to understand why they are preferred for durability and performance in solar applications. ↩

-

Learn how a stronger mechanical grip can enhance the reliability of solar connectors and reduce maintenance costs. ↩

-

Discover the significance of lower electrical resistance in improving efficiency and longevity of solar installations. ↩

-

Explore this link to understand the specific risks associated with U-pin contacts in solar systems and how to mitigate them. ↩

-

Discover the potential fire risks linked to U-pin connectors and how to avoid them in solar projects. ↩

-

Learn about the key factors affecting inspection frequency and how to optimize it for better performance and cost savings. ↩