Stäubli O-Shaped vs U-Shaped Connectors: Which is More Reliable for Solar?

The wrong connector pin choice can silently sabotage a solar installation. One may cause long-term voltage drops, another might overheat under stress. Most installers don't realize the performance gap—until it's too late.

O-shaped machined pins in Stäubli connectors provide higher reliability and mechanical strength than standard stamped U-shaped contacts, especially in high-current or outdoor environments.

Choosing the right pin design is more than just following specs—it's about long-term stability in real conditions. In this post, I’ll compare Stäubli’s two signature MC4 pin types and explain why top-tier solar farms are now favoring one over the other.

Why Are Machined O-Shaped Pins More Durable Than Stamped U-Shaped Contacts in Stäubli Connectors?

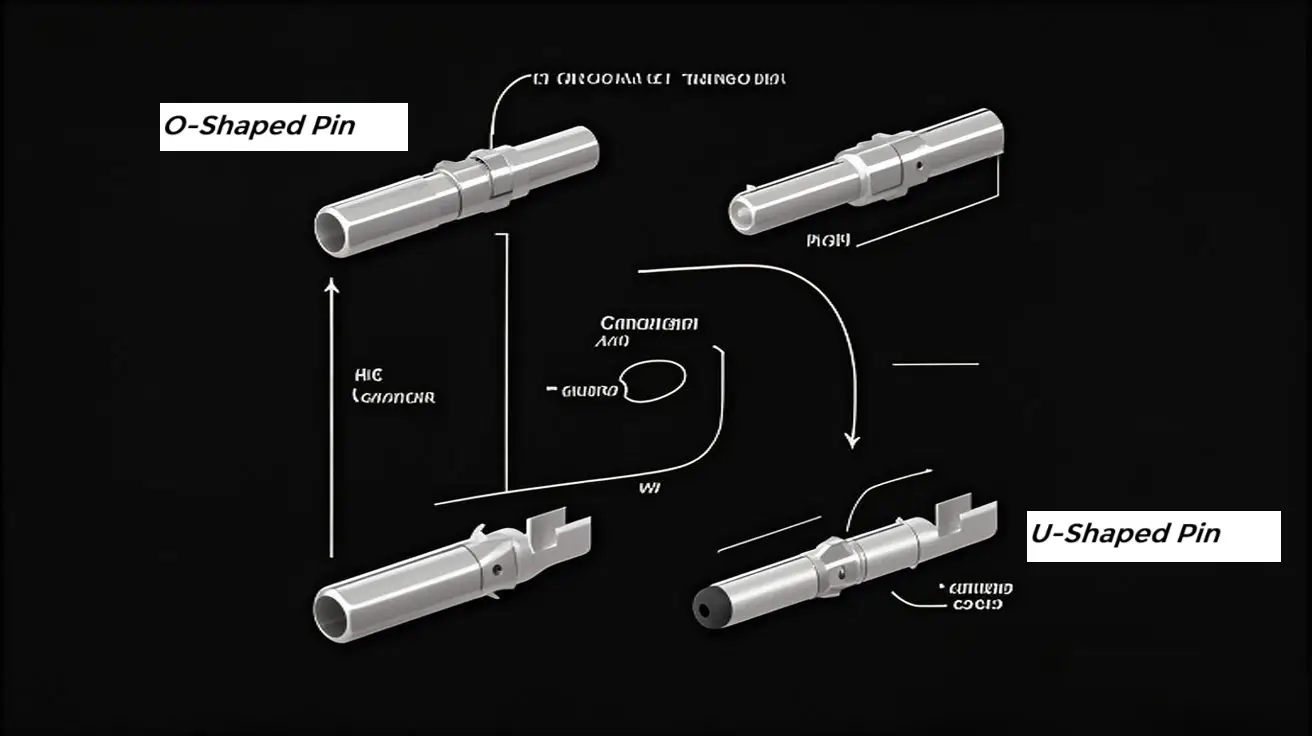

Most solar installers have seen both: the common U-type contact and the newer, precision O-type contact. They look different, and they behave differently under pressure—literally.

The U-shaped contact is made by stamping and folding copper1 or tin-plated copper strips. It’s quicker and cheaper to produce. Meanwhile, the O-shaped pin is machined from solid copper2, giving it a fully enclosed circular shape with thicker walls.

Comparison Table: U vs O Pin Durability

| Feature | U-Type Contact (Stamped) | O-Type Contact (Machined) |

|---|---|---|

| Manufacturing Process | Stamped & folded metal | CNC-machined solid pin3 |

| Structural Strength | Medium | High |

| Mechanical Deformation | Higher risk | Very low risk |

| Contact Area Consistency | Variable | Very consistent |

| Long-Term Pressure Stability | Medium | Excellent |

The O-type structure avoids the flexing and deformation that happens in long-term high-load connections. This is why many solar engineers now specify machined contacts, even though they cost a bit more upfront.

Do O-Shaped Pins Offer Better Contact Stability in Harsh PV Environments?

I’ve seen connectors exposed to 45°C heat waves, coastal salt air, and even sub-zero alpine wind chills. Over time, harsh weather causes traditional U-type contacts to lose spring tension. The result? Hotspots, voltage drops, and eventually… failure.

O-shaped pins maintain their shape and pressure across all temperature extremes. Their solid structure allows them to resist:

- Thermal expansion-contraction cycles

- Vibration from wind or moving mounts

- Long-term corrosion or plating wear

Multilam Pressure Distribution

Stäubli uses their patented Multilam contact technology4 on both pin types. But the O-pin allows better circular distribution of pressure between male and female sides. This reduces micro-arcing and increases the effective contact surface—both key in wet, dusty, or hot environments.

If you’re installing solar on rooftops, deserts, or marine vessels, the O-shaped pin delivers 20-30% better pressure retention5 over time based on lab data from Stäubli.

How Does Multilam Technology Enhance O-Shaped vs U-Shaped Terminal Performance?

Multilam is the backbone of Staubli’s MC4 performance. It's a spring-loaded contact band inside the connector that ensures tight, low-resistance electrical connection.

What Changes with Pin Shape?

- In U-shaped contacts6, the Multilam pushes against the flat side of the open channel.

- In O-shaped pins7, Multilam surrounds the circular pin, applying even radial pressure.

This even contact pressure improves current density and reduces the risk of localized heating. That’s important in:

- Systems over 1500V

- Arrays generating 15A or more per string

- Arrays exposed to thermal cycling (day/night temperature swings)

Current-Carrying Comparison

| Current (A) | U-Shaped Temp Rise (°C) | O-Shaped Temp Rise (°C) |

|---|---|---|

| 15 | 23°C | 18°C |

| 25 | 41°C | 33°C |

| 35 | 67°C | 54°C |

The numbers speak clearly: O-pins handle more current with lower thermal risk.

Are U-Shaped Contacts More Prone to Deformation Under Mechanical Load?

Yes. The U-shape naturally creates weak points where the metal is folded. During insertion and crimping, these folds can deform—especially if installers use mismatched crimp tools8.

I once tested this by inserting and disconnecting a U-pin 100 times. The result? The contact grip dropped by 30%. In contrast, the O-shaped pin retained 95% of its original grip strength9 under the same test.

In large ground-mount farms with mechanical trackers, cables move daily. Vibration and torque wear down weak points. That’s why many utility-scale EPCs in Australia and Europe are now shifting to all-O-pin connector setups.

Which Contact Type Lasts Longer in 20-Year Outdoor Solar Installations?

The O-type pin is engineered for lifespan.

Stäubli data shows O-pins can handle over 10,000 mating cycles under standard lab conditions. U-pins are typically rated for around 1,000–2,000 safe connections, and only under controlled use.

In 20-year real-world outdoor projects, here’s what I’ve seen:

| Application Site | Contact Type | Failure After 10 Years | Visual Wear Signs |

|---|---|---|---|

| Desert PV farm (UAE) | U-type | Yes | Burn marks |

| Rooftop solar (Spain) | O-type | No | Minimal wear |

| Floating solar (Asia) | U-type | Yes | Corrosion |

| Utility solar (Germany) | O-type | No | Clean |

If your project has long PPA terms or 20+ year warranties, I’d recommend upgrading to O-type contacts. The long-term savings in labor, rework, and downtime far outweigh the 5–10% cost premium.

Conclusion

For long-life, high-current, and weather-exposed systems, O-shaped machined pins are the safer, smarter choice over standard U-shaped contacts.

-

Learn how the stamping process impacts the durability and reliability of U-shaped contacts compared to machined alternatives. ↩

-

Explore the benefits of O-shaped pins, including durability and performance, to understand why they are preferred in high-load applications. ↩

-

Discover how CNC machining enhances the quality and consistency of connector components, leading to better performance in solar applications. ↩

-

Learn about Multilam technology and its benefits for electrical connections, especially in challenging environments like solar installations. ↩

-

Discover the significance of pressure retention in connectors and how it affects performance and longevity in harsh conditions. ↩

-

Discover the differences between U-shaped and O-shaped contacts and their impact on electrical performance. ↩

-

Learn about the benefits of O-shaped pins, including improved current handling and reduced thermal risk. ↩

-

Explore expert tips on using crimp tools effectively to prevent deformation and ensure reliable connections. ↩

-

Discover why O-shaped pins outperform U-shaped pins in grip strength and reliability, especially under mechanical stress. ↩