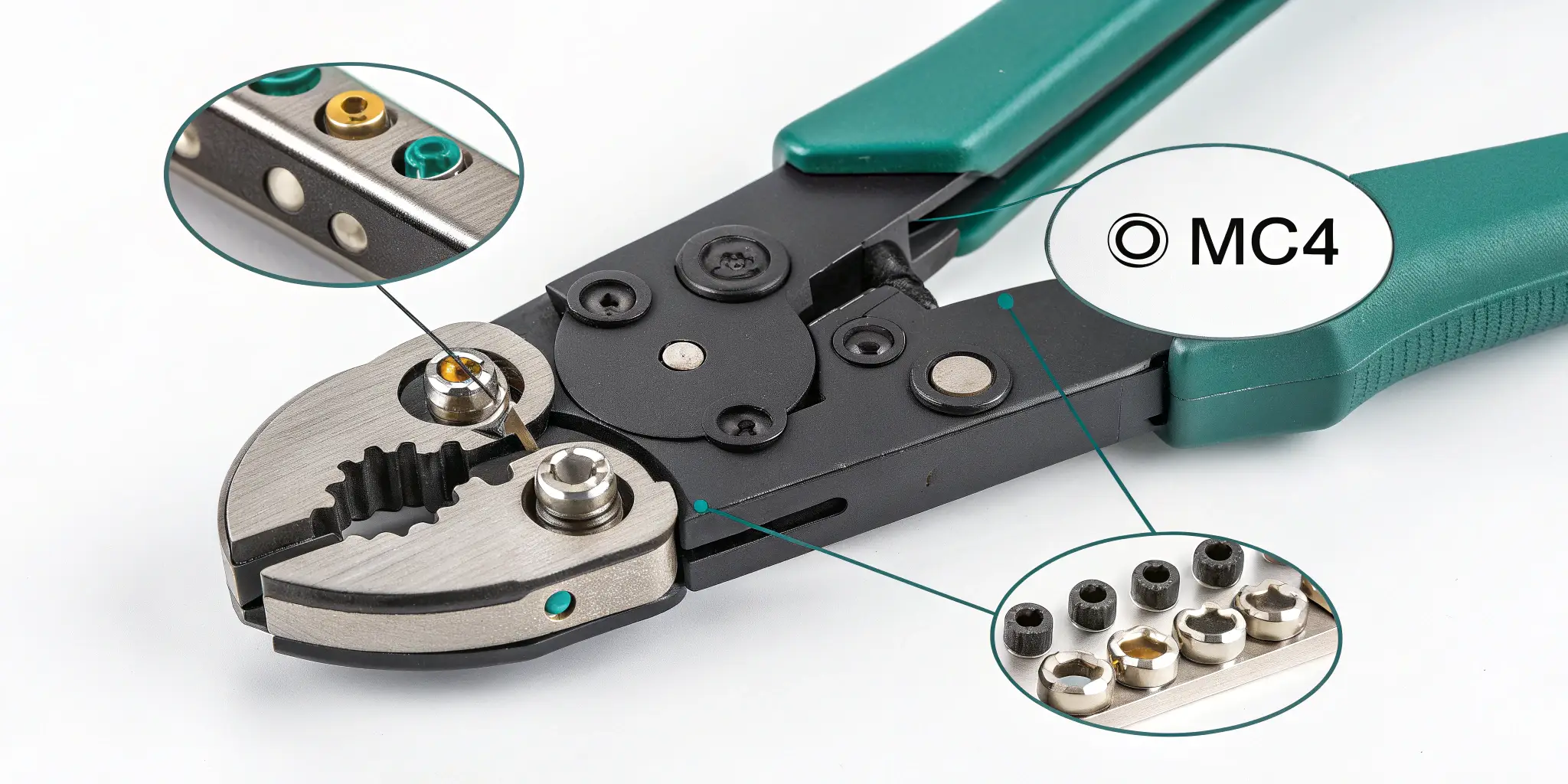

MC4 Pin Shapes: How Crimping Affects PV Connector Safety & Performance

Crimping might seem like a minor task in solar installation—but if your MC4 pin isn’t crimped right, your entire system could fail.

The shape of the MC4 connector pin—U-shaped or O-shaped—affects how strong your crimp is, how safe your connection stays, and how long your solar installation performs in the field.

Not all pin shapes behave the same during crimping. If you want fewer call-backs, longer lifespan, and safer systems, keep reading to understand how pin geometry makes a difference.

Does the Shape of the Pin Impact Crimping Strength in MC4 Connectors?

A good crimp is essential to any MC4 connection. It keeps the current flowing efficiently while locking the cable securely. But how does pin shape affect the strength of that crimp?

O-shaped pins1 offer more consistent compression and better mechanical strength during crimping compared to U-shaped pins2.

Why shape matters during crimping:

- U-shaped pins are usually stamped from flat metal and have open sides. During crimping, these sides can collapse unevenly if pressure isn’t applied correctly. This inconsistency can lead to weak crimps.

- O-shaped pins, which are machined or drawn into a round profile, give full 360° contact with the crimp tool. The result? A uniform grip and tighter bond with the cable strands.

| Pin Shape | Crimping Consistency | Risk of Deformation | Grip on Cable |

|---|---|---|---|

| U-shaped | Medium | High | Moderate |

| O-shaped | High | Low | Strong |

In my own experience supplying Staubli MC4 connectors to solar projects in coastal Australia, installers noticed fewer pull-outs and lower contact resistance when switching to O-shaped versions. That small change had a huge effect on long-term reliability.

Why Do Improperly Crimped U-Shaped Contacts Lead to Connector Failures?

I’ve seen it many times: a good-quality solar panel, decent MC4 connector3, but poor crimping4 ruins everything.

U-shaped contacts5 are more vulnerable to inconsistent or weak crimps, which can cause loose connections, overheating, and even arcing.

Common failure points with U-type contacts:

- Sidewall collapse: During crimping, U-shaped pins can fold or crush if the tool isn’t aligned perfectly.

- Uneven pressure: This causes poor contact with the cable strands, increasing resistance.

- Micro gaps: These gaps let in moisture or dust over time, which can lead to corrosion.

A customer once shared photos of melted MC4 connectors just 18 months after install. The issue? The crimps were fine by eye—but they used U-type pins with a worn crimp tool. The slight deformity went unnoticed, but it created heat buildup that ruined the contact.

This kind of hidden risk is why crimping strength and pin shape must work together.

Are O-Shaped Pins Easier to Crimp Consistently in Field Installations?

Yes—especially when you’re doing installations in less-than-ideal conditions like rooftop angles or dusty ground-mounted systems.

O-shaped pins reduce the margin of error for field installers and improve uniformity, even when working quickly or at awkward angles.

%[Technician crimping O-shaped MC4 pin onto cable with firm grip

Why O-type pins are easier for field work:

- Round shape guides the tool: Crimp jaws close evenly around the full surface, preventing slippage or misalignment.

- Fewer reworks: With U-shaped pins, a small mistake means re-stripping and re-crimping. That’s time lost.

- Better training results: New installers achieve more reliable crimps with O-type contacts due to their forgiving shape.

As someone who has helped train installation teams, I always recommend O-shaped pins for projects with tight deadlines or rotating crews. Even if the installer is inexperienced, the crimp outcome is far more stable.

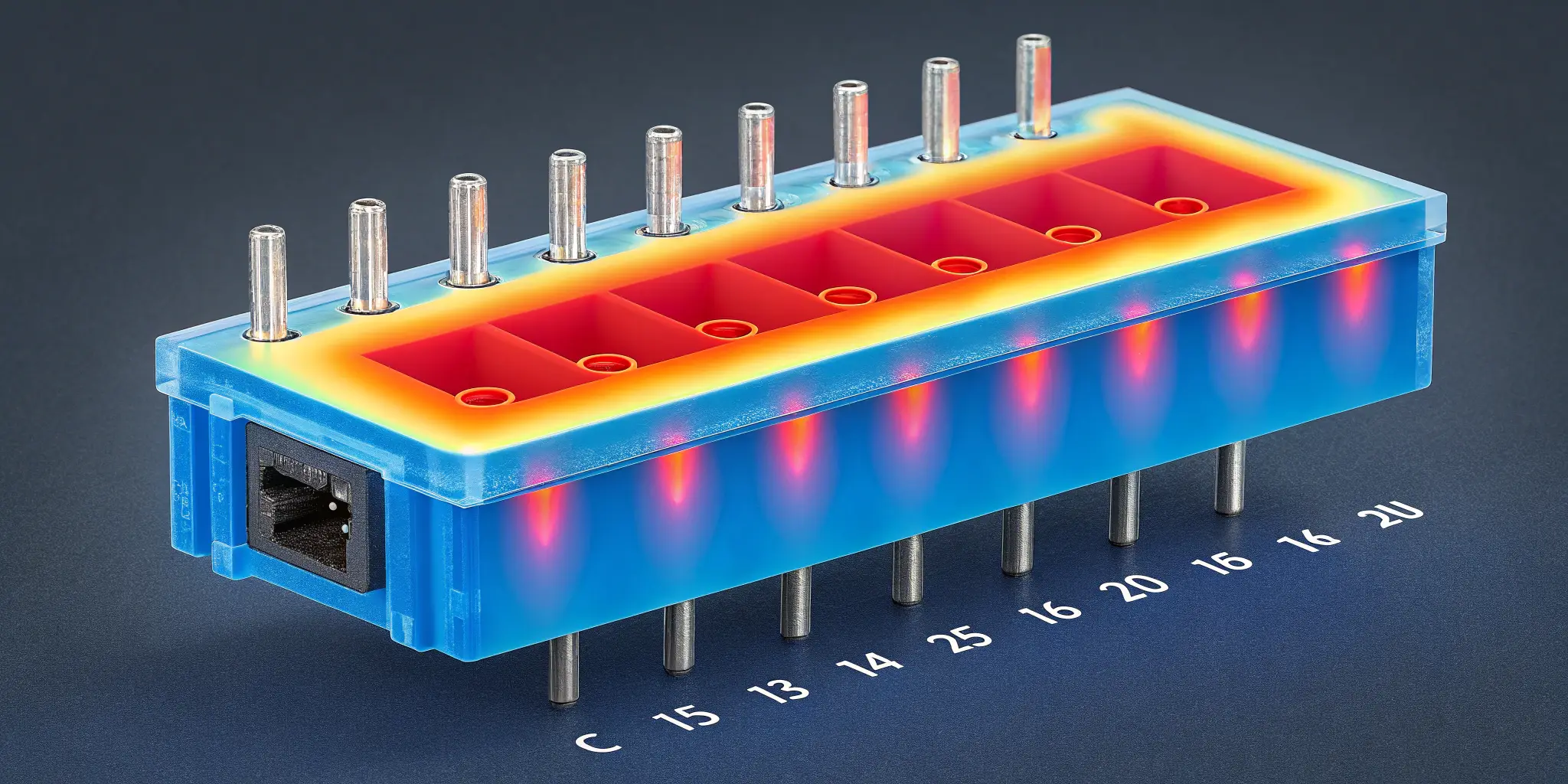

How Does Pin Geometry Influence Electrical Contact Resistance Over Time?

Crimping isn’t just about holding a cable—it’s about making sure the electrical flow is smooth and uninterrupted.

The geometry of the contact affects how much resistance builds up over time. O-shaped pins offer a more secure and lower-resistance connection over the long run.

What causes resistance to increase?

- Micro-motion at the crimp point: Loose crimps allow the cable to move slightly, breaking the tight bond.

- Corrosion at contact surfaces: Especially in humid or coastal areas, gaps in the crimp let in air or water.

- Cyclic thermal expansion: As temperatures change, the crimped connection expands and contracts. Weak crimps can loosen further.

| Factor | U-Shaped Contact | O-Shaped Contact |

|---|---|---|

| Initial resistance (mΩ) | ~1.5 | ~0.8 |

| Resistance after 5 years | ~2.3 | ~1.1 |

| Moisture ingress risk | High | Low |

This is where O-type pins shine. Their full-circle design keeps pressure distributed evenly, maintaining low resistance over years of operation. That’s critical for systems where power loss isn’t an option.

What Are the Long-Term Safety Risks of Poor Crimping in PV Connectors?

Now we get to the core issue: safety.

Improperly crimped MC4 connectors are one of the top causes of PV system fires—and U-shaped contacts are more often involved.

Key long-term safety risks:

- Arcing: When current jumps across gaps in a loose connection, it generates extreme heat.

- Connector meltdown6: Plastic housings aren’t designed to handle internal heat from high-resistance crimps.

- Warranty loss7: Some tier-1 panel makers require certified crimping tools and connectors to maintain warranty validity.

I always tell my clients: even if your system is small, one bad crimp can cost you thousands. Choosing O-shaped pins reduces that risk significantly by giving you better mechanical and electrical stability.

Conclusion

The shape of your MC4 contact pin can make or break your solar installation. For better crimping quality, longer lifespan, and safer connections, O-shaped pins are worth the upgrade.

-

Explore the benefits of O-shaped pins for better crimping strength and reliability in MC4 connectors. ↩

-

Learn about the limitations of U-shaped pins and why they may lead to weaker connections in MC4 crimping. ↩

-

Learning about MC4 connectors can provide insights into their use in solar applications and best practices for installation. ↩

-

Exploring the effects of poor crimping can enhance your knowledge of connector reliability and performance. ↩

-

Understanding U-shaped contacts can help you avoid common pitfalls in crimping and ensure reliable connections. ↩

-

Learn about connector meltdown to ensure your solar system operates safely and efficiently. ↩

-

Explore warranty loss implications to protect your investment in solar technology. ↩