How to Import Custom Solar Panels from China & Avoid Microcracks in Small Panels?

Small solar panels look simple. But once microcracks appear, power drops, failures come early, and disputes follow fast.

From my experience, small solar panels are not naturally more prone to microcracks, but poor design, handling, and inspection make the risk much higher.

I have worked with many custom small-panel projects. Some performed well for years. Others failed within months. The difference was never size alone. It was how microcrack risk was managed from factory to delivery.

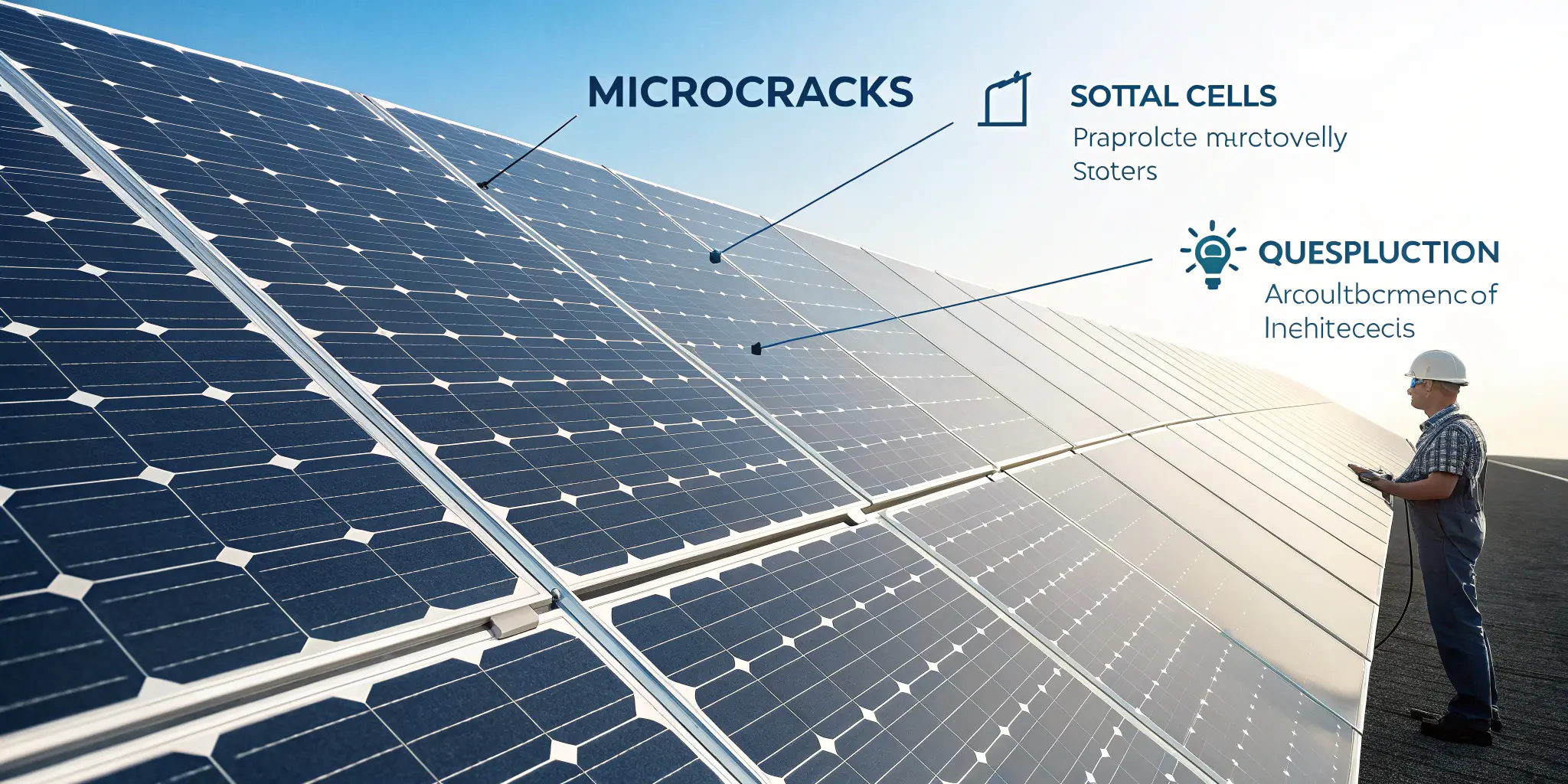

Microcracks are dangerous because most of them are invisible.

I rely on EL testing1 before and after lamination to detect hidden microcracks2 that cannot be seen by the naked eye.

Why visual inspection always fails

Many buyers trust visual checks. If the panel looks clean, they assume it is safe. This approach is wrong.

Microcracks form inside the silicon cell. They do not always reach the surface. Even experienced inspectors cannot detect them without special tools.

I learned this lesson early. Panels passed visual checks. Power tests looked fine. But after months of use, output dropped sharply.

EL testing as the only reliable method

Electroluminescence testing shows cracks clearly. It reveals broken fingers, dark areas, and inactive regions.

I require:

- EL test before lamination

- EL test after lamination

- Random EL test after packaging

This three-step check catches most risks.

Why small panels need stricter EL rules

Small panels often use thinner cells. Thin cells crack more easily during soldering and stringing.

In small formats, one cracked cell can affect a large percentage of total output. That is why I push for 100% EL testing, not sampling.

Post-shipment inspection matters

Microcracks can grow during shipping. Vibration and shock make small cracks worse.

For high-risk orders, I request EL checks after arrival. This protects me in disputes and confirms transport quality.

Detection is not optional. Without EL testing, microcracks remain hidden until it is too late.

What materials reduce risk?

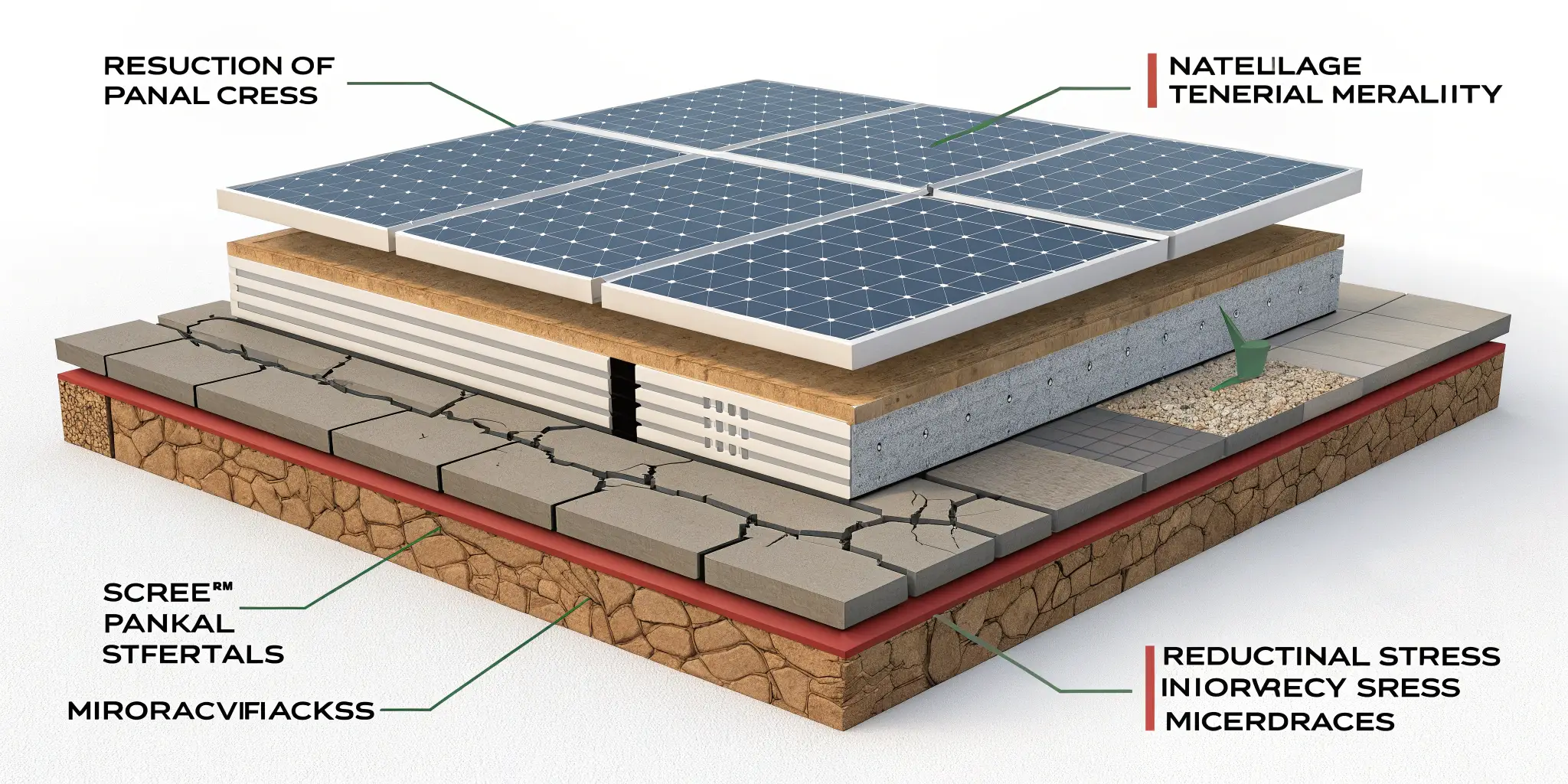

Materials determine how stress spreads inside the panel.

I reduce microcrack risk by selecting thicker glass3, stable encapsulants, and reinforced frames for small custom panels.

Glass thickness and stiffness

Thin glass bends more easily. Bending transfers stress directly to cells.

For small panels, I prefer:

- Tempered glass with higher stiffness

- Avoiding ultra-thin glass unless flexibility is required

Glass choice alone can reduce crack risk significantly.

Encapsulant quality matters

Cheap EVA ages fast. As it degrades, it loses elasticity. Stress transfers to cells instead of being absorbed.

I request:

- Certified EVA or POE

- Proven lamination temperature control

- Uniform encapsulation thickness

Encapsulants are invisible but critical.

Frame and edge protection

Small panels often use lighter frames. This saves cost but increases vibration damage.

I prefer:

- Closed-frame designs

- Reinforced corners

- Even pressure distribution

Frames do more than hold shape. They protect cells from shock.

Cell thickness trade-offs

Thin cells improve efficiency and weight. But they crack easier.

For durability-focused projects, I accept slightly lower efficiency in exchange for thicker, stronger cells.

Materials define risk. Once the panel is built, changes are impossible.

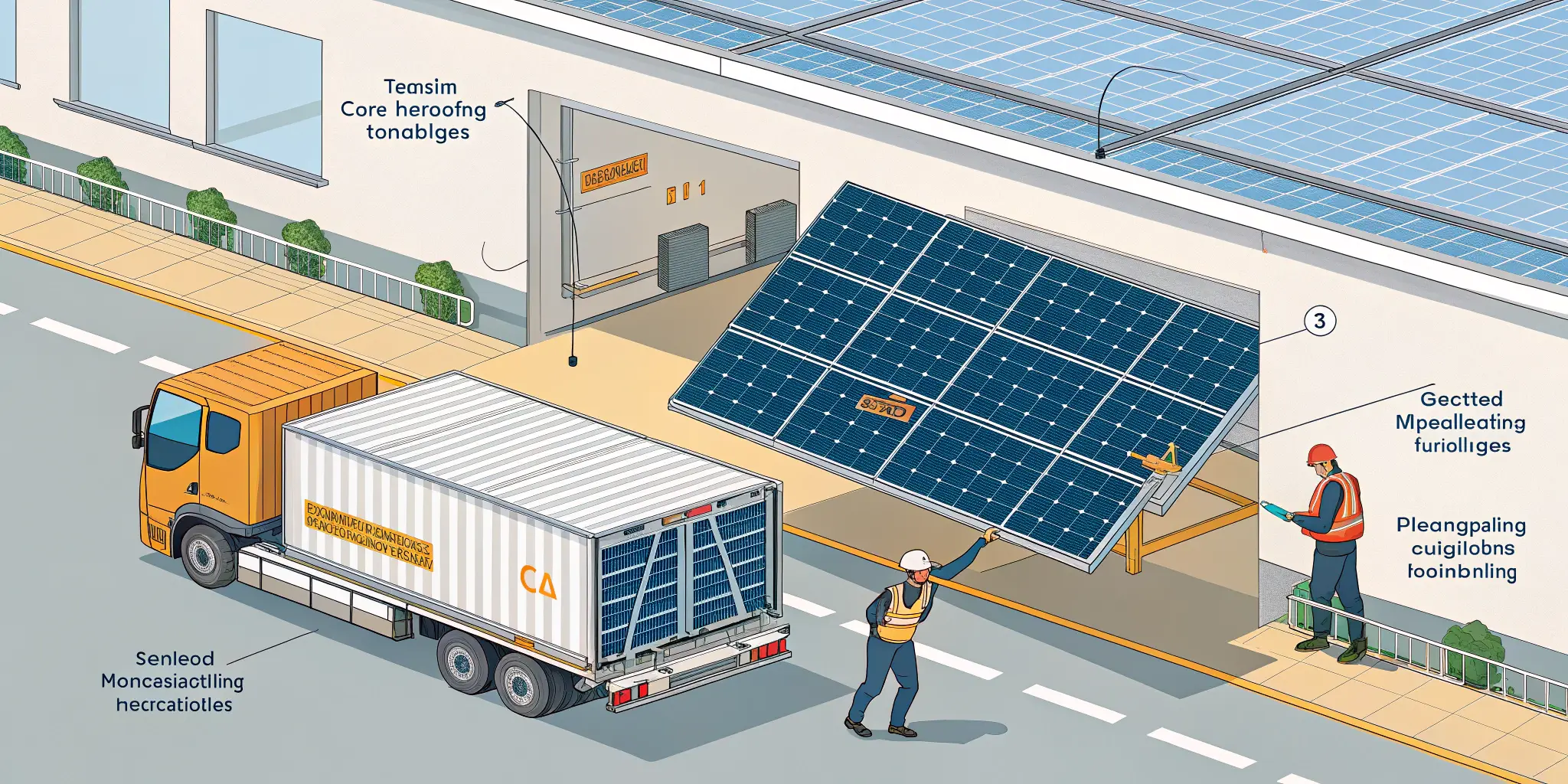

How do transport and handling affect panels?

Many microcracks do not start in the factory. They start on the road.

Transport vibration and poor handling4 are among the biggest causes of microcracks in small solar panels.

Handling stress in production

Manual production lines increase risk. Uneven soldering heat and manual lifting create stress points.

I always ask:

- Is stringing automated or manual?

- Are fixtures designed for small panels?

- Are operators trained for thin cells?

Manual handling raises crack probability.

Packaging quality is critical5

Small panels often ship in bulk. This is dangerous.

I require:

- Double-corrugated cartons

- Foam separators

- No loose stacking

Vibration during long shipping routes magnifies any existing microcracks.

Vibration during shipping

Sea freight, trucking, and air cargo all introduce vibration. Repeated small shocks slowly extend cracks.

This is why I request:

- Drop test reports

- Vibration test references

- Clear stacking limits

Transport damage is silent but destructive.

Last-mile handling risk

Many panels break at the final stage. Warehouses and installers are often careless with small panels.

I label cartons clearly and include handling instructions. Small steps reduce large losses.

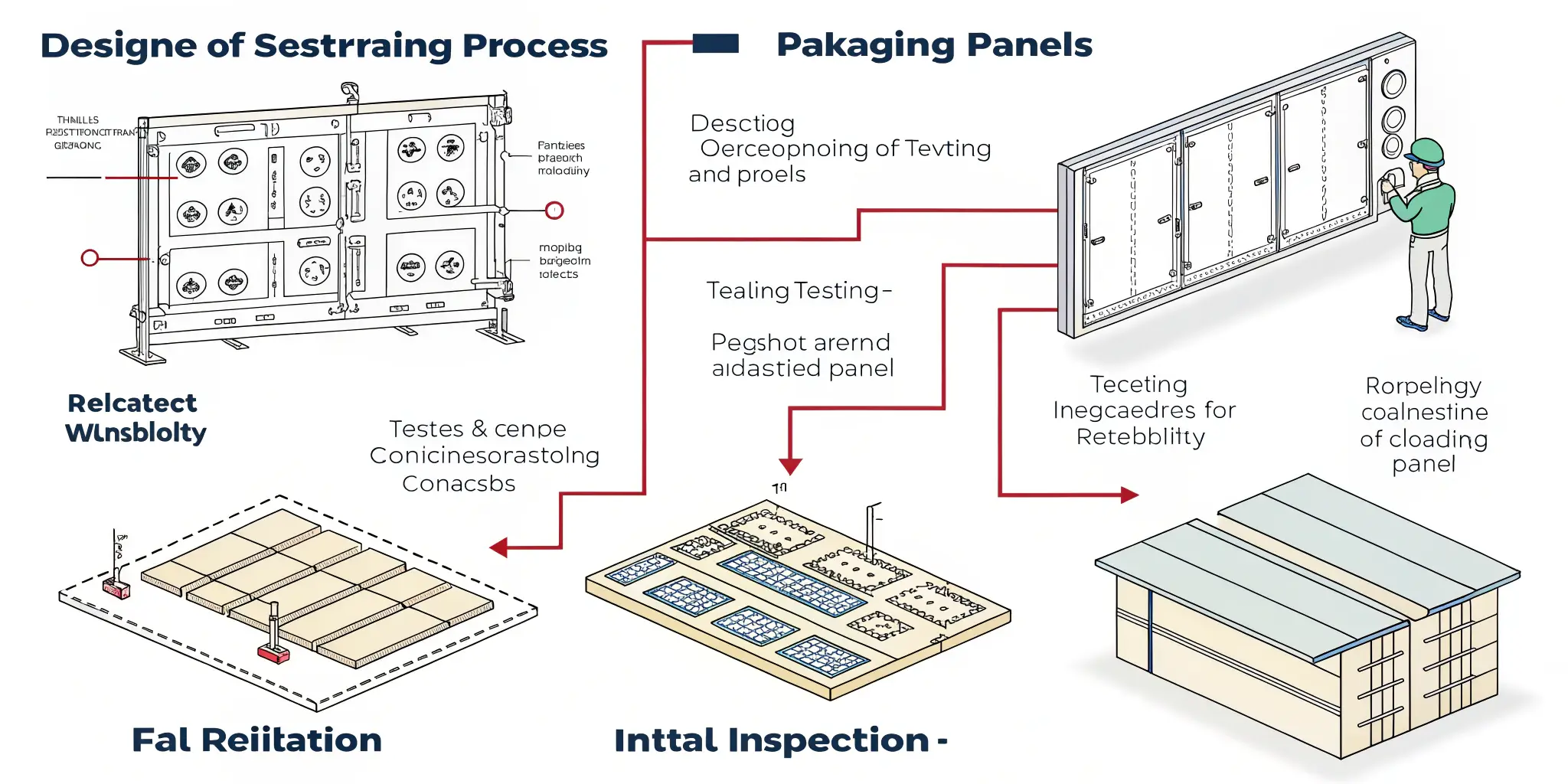

How do I prevent early failure6?

Prevention is cheaper than replacement.

I prevent early failure by controlling design, testing, packaging, and inspection as one complete system.

Design rules I always follow

I avoid:

- Excessive cell cutting

- Extreme aspect ratios

- Unsupported glass spans

Compact design must still respect mechanical balance.

Production controls that matter

I insist on:

- Controlled soldering temperatures

- Dedicated small-panel fixtures

- Lower handling frequency

Small changes in process reduce crack formation.

Inspection strategy

Inspection is layered:

- EL before lamination

- EL after lamination

- Random EL after shipment

Skipping one step creates blind spots.

Documentation and accountability

I include microcrack limits in contracts. Panels with severe cracks are rejected.

This changes factory behavior. When rejection is real, quality improves.

Early failure is never accidental. It is usually designed into the process by ignoring risk.

Conclusion

Small solar panels are not fragile by default. Microcracks come from poor control. With proper design, testing, and transport discipline, small panels can remain reliable for years.

-

Explore this link to understand how EL testing can effectively detect hidden microcracks in solar panels, ensuring their reliability. ↩

-

Learn about the impact of microcracks on solar panel efficiency and why detection is crucial for long-term performance. ↩

-

Exploring this link will reveal how thicker glass enhances durability and reduces microcrack risks in solar panels. ↩

-

Understanding the impact of transport vibration can help improve solar panel durability and reduce microcracks. ↩

-

Exploring packaging quality can reveal best practices to prevent damage during shipping and ensure panel integrity. ↩

-

Understanding best practices can help you implement effective strategies to minimize early failures in your products. ↩