What international certifications are required when importing PV connectors from China?

I know many importers feel confused when they look at the certification rules for PV connectors, especially when each market has different standards.

PV connectors imported from China must follow IEC 62852, TÜV, UL, CE, and IP67/IP68 protection requirements, depending on the destination market. These certifications confirm safety, durability, and long-term outdoor performance.

I want to walk you through the certifications that matter the most, and I will explain them in simple terms so you can avoid risks later in your solar projects.

Is TÜV mandatory for the Australian market?

Many buyers worry about whether TÜV approval is necessary because they hear mixed information from different suppliers.

TÜV certification1 is not legally mandatory for all markets, but it is strongly preferred in Australia because most solar farms use IEC 628522-approved connectors for safety and long-term stability.

Understanding the role of TÜV in real projects

When I source PV connectors for clients, I notice that Australian EPCs often ask for TÜV because it follows the IEC 62852 standard. This standard checks heat resistance, fire safety, temperature cycling, humidity, UV aging, and contact resistance. These tests help reduce failure risks in harsh outdoor conditions.

Why most Australian buyers prefer TÜV

- Many large farms follow global best practices.

- TÜV-certified products often come from more stable factories.

- The test reports give buyers confidence during inspections.

Difference between TÜV and IEC 62852

| Item | IEC 62852 | TÜV |

|---|---|---|

| Nature | International standard | Certification body |

| Scope | Safety + performance | Testing + auditing |

| Meaning | Defines the rules | Verifies compliance |

| Value to importers | Required by many projects | Strong proof of quality |

Real-world impact on imports

In my experience, most customs brokers in Australia will not block PV connectors without TÜV, but project owners might reject them later. So even if the import step is smooth, the installation phase can become a problem.

This is why I always tell buyers to choose connectors with both TÜV and IEC 62852. It lowers long-term risks and avoids disputes with installers.

Will CE or UL impact the import process?

Many buyers feel lost when they hear suppliers talk about CE, UL, RCM, and other marks.

CE and UL both affect the import process because they show compliance with safety standards. CE is important for Europe, and UL is required in North America.

Why CE and UL matter for PV connectors

I have worked with many customers who ship the same connector model to different markets. They often ask if CE or UL will delay customs clearance. From my experience, the answer depends on the destination.

CE marking for Europe3

CE is a self-declaration, but importers still need the correct technical file. For PV connectors, CE often covers:

- RoHS

- Low Voltage Directive

- EMC (sometimes indirectly)

UL 6703 for the US and Canada4

UL 6703 is more strict. It checks:

- Mechanical strength

- Temperature resistance

- Current rating

- Long-term outdoor safety

If your connectors go to:

- USA → You need UL 6703

- Canada → You need UL or CSA

- Australia → UL is not required

- Europe → CE is required

How certifications influence customs

| Market | Required | Impact on Import |

|---|---|---|

| EU | CE | Customs may check documents |

| USA | UL 6703 | Needed for project approval |

| Canada | CSA or UL | Required for compliance |

| Australia | CE or TÜV | TÜV preferred for farms |

Missing certifications usually does not stop customs, but it increases the risk of project rejection later. This is a mistake many first-time importers make.

Can certification numbers be verified online?

Many buyers worry about fake certification numbers because the PV connector market in China is mixed.

Yes, most TÜV, UL, and CE-related certifications can be verified online. This helps you confirm that the supplier is not using fake reports or expired approvals.

How to confirm certification legitimacy

Over the years, I have learned a simple process to check if a connector is genuinely certified. Most certification bodies now offer online lookup features.

How to check TÜV certificates

Go to the TÜV Rheinland Certipedia website and search by:

- Certificate number

- Factory name

- Product model

- Report number

You will see:

- Validity period

- Scope of certification

- Testing standards (e.g., IEC 62852)

- Factory audit status

How to check UL numbers5

UL has a public database where you can check:

- File number (E-number)

- Product type

- Factory location

- Voltage rating

If the certificate does not match the factory name, stop the order immediately.

Why online verification is important

| Risk | How verification helps |

|---|---|

| Fake certificates | Identifies mismatched data |

| Expired documents | Shows expiration dates |

| Wrong models | Confirms scope and test results |

| Supplier fraud | Verifies real production capability |

I always advise importers to save screenshots and include them in contract files to protect themselves.

Are non-certified products risky for long-term projects?

Many buyers want to save money and ask if they can choose connectors without TÜV, UL, or CE.

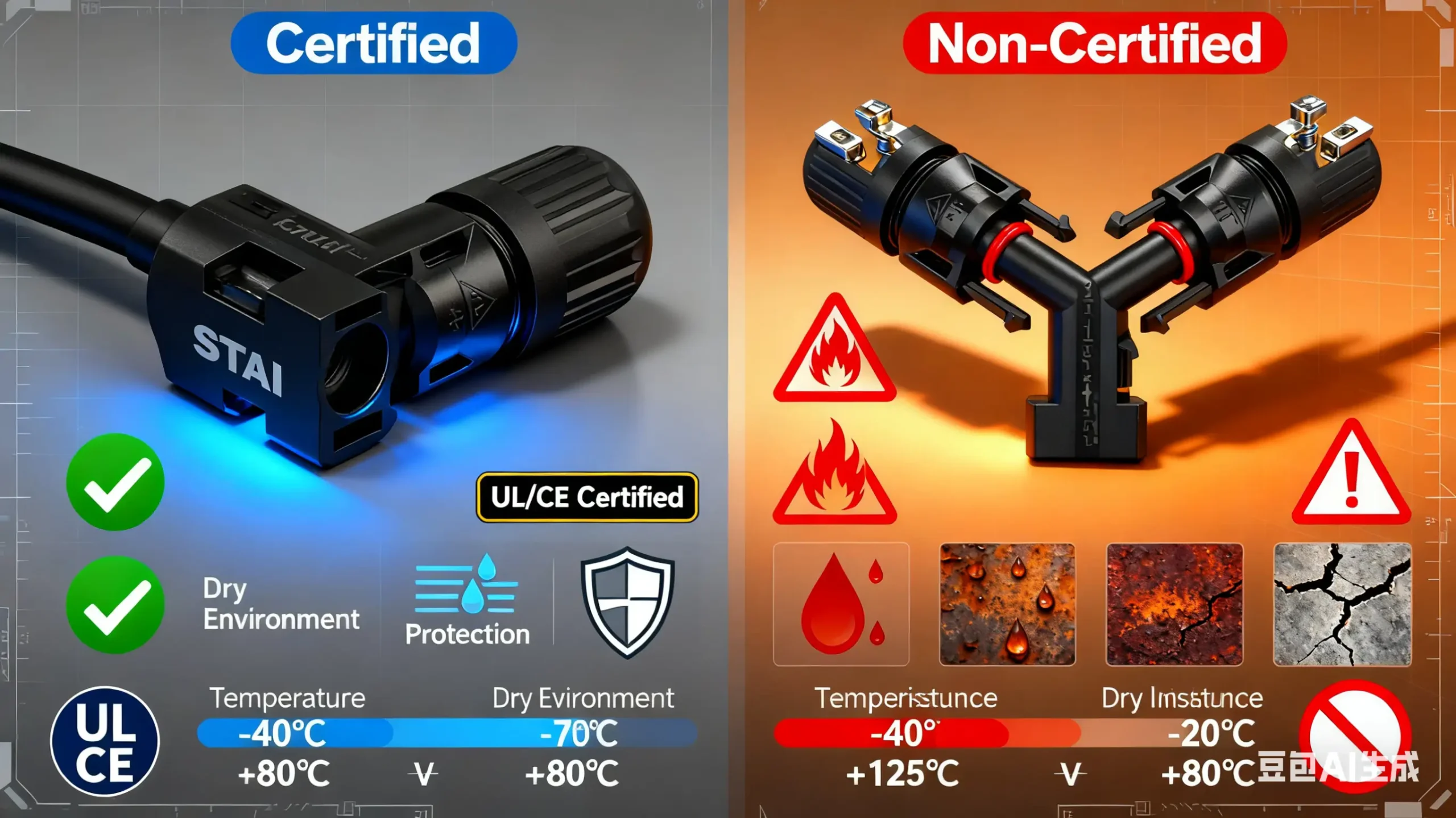

Non-certified connectors6 are risky because they often fail earlier in outdoor solar systems. They may pass short-term tests but fail under long-term heat, moisture, or corrosion.

Why certifications reduce project risks

In my work, I have seen many project failures7 caused by non-certified connectors8. These failures include overheating, melting, arc faults, and fires. Most of them were caused by:

- Poor internal metal quality

- Weak sealing structure

- Bad crimping

- Poor insulation material

What certifications actually test

| Certification | What it checks |

|---|---|

| IEC 62852 | Safety + durability |

| TÜV | Environmental + mechanical tests |

| UL 6703 | Fire + long-term outdoor safety |

| CE | Base compliance for EU |

| IP67/IP689 | Waterproof + dustproof rating |

IP67/IP68 is especially important. Outdoor connectors face rain, snow, dust, and UV exposure. Without proper sealing, moisture gets inside and causes corrosion.

What happens without certifications

Here are common problems I see in the field:

- Connector heating at 30–50°C above normal

- Contact resistance increasing after one year

- Water entry inside the connector housing

- Cracking from UV exposure

- Fire hazards during high-current operation

Why certified connectors are a better long-term choice

Certified connectors usually come from:

- Better raw materials

- More stable factory processes

- Verified housing and sealing structures

- Verified terminal plating and resistance levels

In long-term solar farms, the cost of replacing one failed connector can be higher than buying a certified product to begin with.

Conclusion

Certifications help you reduce long-term risks, meet project standards, and avoid costly failures in real installations.

-

Explore this link to understand the importance of TÜV certification for solar products in Australia and its impact on safety and compliance. ↩

-

Learn about the IEC 62852 standard to see how it ensures safety and performance in solar installations, crucial for informed purchasing decisions. ↩

-

Understanding CE marking is crucial for compliance in Europe, ensuring smooth customs clearance and market access. ↩

-

Exploring UL 6703 helps ensure your products meet safety standards, preventing delays and rejections in the import process. ↩

-

This resource will help you understand how to verify UL numbers, protecting you from potential fraud. ↩

-

Learn why certified connectors are essential for ensuring safety and reliability in solar energy systems. ↩

-

Investigate the common causes of project failures to avoid costly mistakes in solar installations. ↩

-

Explore the risks associated with non-certified connectors to understand their impact on solar project longevity. ↩

-

Discover the significance of IP67/IP68 ratings in protecting outdoor connectors from environmental damage. ↩