Can I request product samples before bulk purchasing genuine Stäubli PV connectors from China?

I know it can feel risky to buy a full shipment without touching the product first, especially when the goods are Stäubli PV connectors that affect system safety.

Yes, I can request genuine Stäubli PV connector samples before I place a bulk order, and this helps me verify quality, compatibility, and authenticity.

When I test samples before I buy in larger quantities, I lower my project risks. I avoid compatibility mistakes, model mismatches, or quality problems that might appear only after installation. This is why I see samples as an important step in my decision process.

How many samples can I request for testing?

Sometimes it is hard to decide how many samples I should ask for, because I want enough to test, but I do not want to make the supplier uncomfortable.

I can request a small quantity of genuine Stäubli connector samples1, usually between two and ten pairs, depending on my testing needs.

A deeper look at how many samples I should request and why it matters

I ask for a small number of samples because this amount is enough for me to complete a full evaluation. When I test PV connectors, I usually check their appearance, their internal structure, and how well they mate. I want to see if the male and female connectors feel firm when I lock them together. I also test cable compatibility, crimping quality, and how the connector behaves after I simulate real installation steps.

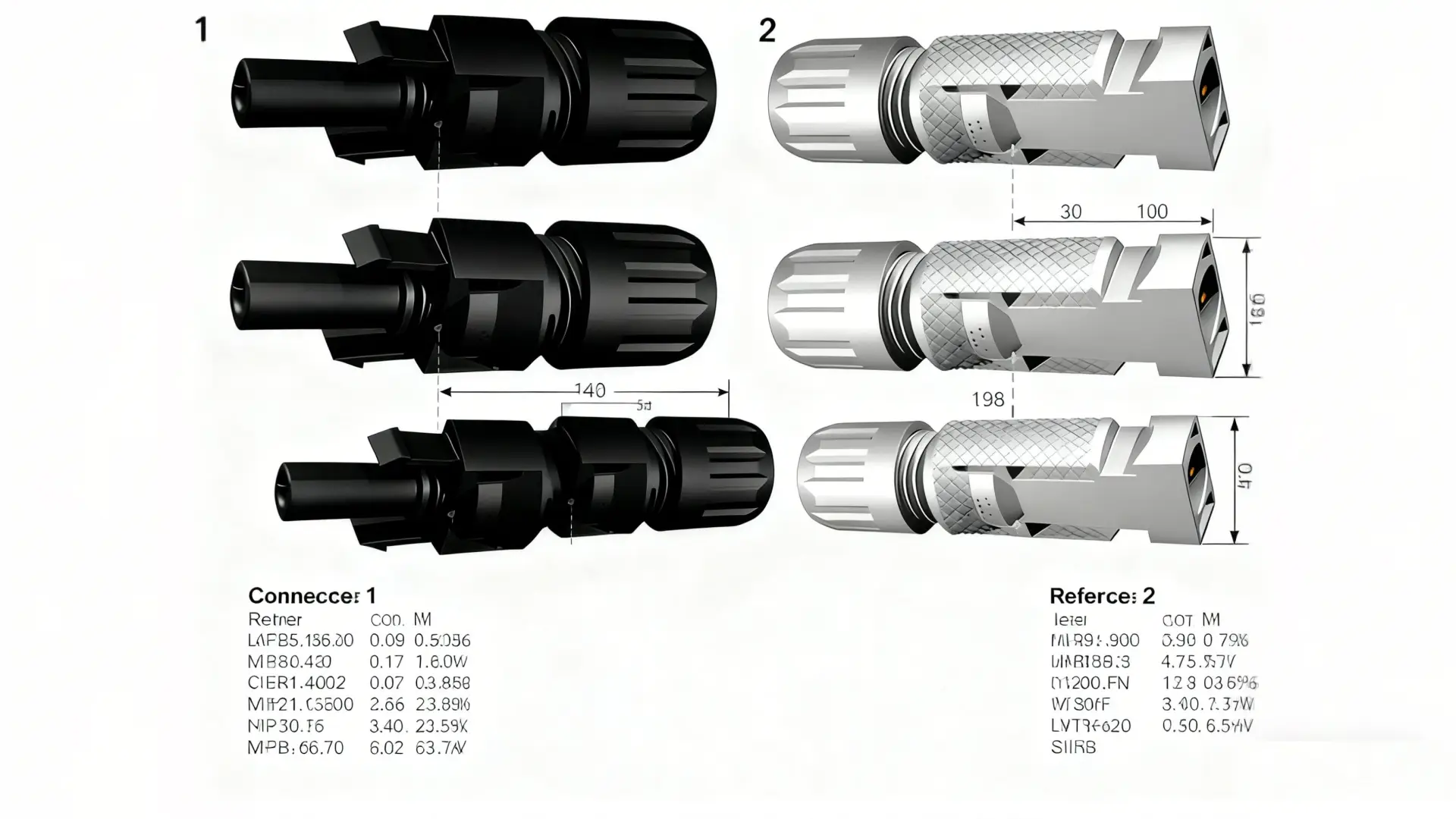

When I request samples, I confirm the exact Stäubli part number. This helps me avoid confusion between MC4 and MC4-Evo22, because these two models have different voltage ratings and sometimes different tooling requirements. The supplier should give me the correct part number, such as PV-KBT4-EVO2 or PV-KST4. The part number printed on the sample should match the official datasheet.

Many suppliers in China, including authorized distributors and qualified trading companies, can provide genuine Stäubli samples. This is normal in the solar industry. Some suppliers allow me to request two pairs. Some allow five, and others allow ten. The number usually depends on my testing plan3. If I need to test mating forces, crimping, and environmental exposure, then I ask for more samples. If I only want to confirm authenticity and appearance, then I ask for fewer.

Below is a simple table that helps me decide how many samples to request:

| Testing Need | Recommended Sample Quantity | Why |

|---|---|---|

| Basic appearance check | 2 pairs | Enough to confirm authenticity and markings |

| Fit and mating test | 4 pairs | Allows me to test both ends and repeat the mating twice |

| Crimping and installation test | 6–8 pairs | Needed because crimping permanently uses up terminals |

| Comparative supplier evaluation | 5–10 pairs per supplier | I need enough samples to compare consistency |

| Environmental simulation | 8–10 pairs | High-level testing needs multiple units |

When I request samples, I also ask whether they are from the same production batch as future bulk orders. This helps me check consistency. If the supplier sends me premium samples but delivers lower-quality bulk goods later, then I will quickly see the difference.

I find that asking for a reasonable number of samples shows the supplier that I am serious. It helps both sides confirm expectations before we move to a larger cooperation.

Do I need to pay for samples or shipping costs?

Many buyers hesitate to ask for samples because they worry about the cost. I also used to wonder if suppliers expect buyers to pay full price.

Most suppliers offer Stäubli PV connector samples4 either free or at a shared cost, but I usually need to cover the shipping fee.

A deeper look at sample pricing5, shipping expectations, and why payment terms matter

When I deal with genuine Stäubli products, I understand that these connectors are not cheap. They follow strict quality standards and come from a controlled supply chain. Because of this, many suppliers cannot give many free samples. However, most good suppliers accept cost-sharing or small payments. This is common practice. Offering samples at a small charge also helps filter out non-serious buyers.

I also prepare to pay for shipping. International shipping fees6 depend on the carrier I choose. Express options like DHL or FedEx cost more, but I usually prefer them because samples are light and I want them fast. When I test samples before a project deadline, fast shipping helps me avoid delays.

Below is a simple table that shows what different suppliers might expect:

| Supplier Type | Sample Cost | Shipping Cost | Standard Policy |

|---|---|---|---|

| Authorized distributor | Sometimes free or discounted | Usually paid by buyer | Wants to confirm buyer identity first |

| Reputable trading company | Cost-sharing (small fee) | Paid by buyer | Common for global customers |

| Large exporter | Free for long-term clients | Paid by buyer | Depends on purchase history |

| New supplier | Paid sample | Paid by buyer | Needs to protect cost |

When I confirm the cost, I also ask the supplier to send me clear photos of the samples before shipping. I check the packaging too. Genuine Stäubli packaging has clear printing, correct font, proper labeling, and batch codes. If I am paying for a sample, I want to make sure I receive exactly the right model.

I also check if the supplier can handle small test orders7. Many legitimate suppliers in China accept low-quantity trial orders before bulk shipments. This helps me test logistics performance and documentation accuracy. If a supplier refuses to send samples or refuses any small order, this is often a warning sign.

Paying a small amount for samples is normal and often worth it. It helps me avoid far bigger losses from buying the wrong model or receiving inauthentic goods. I see it as a small investment for long-term reliability.

What should I check when testing sample quality?

When I receive the samples, I want to know exactly how to assess them. I want to avoid missing important details that might affect safety or performance later.

I check authenticity, batch codes, fit, crimping compatibility8, markings, tooling requirements, and installation feel when I test Stäubli sample quality9.

A deeper look at how to test sample quality the right way

When I evaluate a Stäubli sample, I start with the part number. I compare the printed part number on the connector to the datasheet. I check that the voltage rating is correct. MC4 usually supports up to around 1000 V. MC4-Evo210 supports up to around 1500 V. If my solar project runs at 1500 V, I must select MC4-Evo2.

Then I check the cable size. Stäubli connectors support common PV cable sizes like 4 mm², 6 mm², and sometimes 10 mm². The sample should match the cable I plan to use. If the cable size does not match, the crimping will not be reliable.

Here are the main checks I perform:

| Test Category | What I Check | Why It Matters |

|---|---|---|

| Authenticity | Stäubli logo, model code, batch code | Helps avoid counterfeit products |

| Physical build | Material feel, surface finish, sealing | Ensures durability |

| Locking mechanism | Locking click and resistance | Ensures stable mating |

| Mating fit | Smooth but firm connection | Prevents overheating and failure |

| Markings | Voltage rating, certification marks | Confirms compliance |

| Crimping | Correct die size and crimp result | Ensures safe electrical performance |

| Documentation | Datasheet, certificate of conformity | Needed for warranty and import clearance |

| Batch alignment | Same batch or near batch as bulk order | Helps ensure consistency |

I also look inside the connector. Genuine Stäubli connectors have a clean internal layout with precise metal contacts. The Multilam technology on the contact surface should look even and clean. The spring mechanism should feel firm.

During testing, I also check tooling compatibility. MC4 and MC4-Evo2 sometimes require different die shapes. If I use the wrong crimping tool, the connector will not hold the conductor firmly. This can cause high resistance and heat buildup.

Then I test installation. I crimp the pin, insert it, and twist the connector. I tighten the sealing nut with the recommended torque. During this step, I can feel if the connector is well-designed. Good connectors feel stable and do not wobble.

Finally, I test environmental resistance11. Sometimes I expose the sample to heat or sunlight for a short period. This does not replicate full field aging, but it gives me a sense of the material quality.

When I test samples thoroughly, I gain confidence that the bulk order will meet my expectations.

Can I compare samples from multiple suppliers to choose the best one?

I often want to compare more than one supplier. This helps me avoid dependence on a single source and gives me more insight into the supply chain.

Yes, I can compare samples from multiple suppliers, and this helps me evaluate consistency, response speed, documentation accuracy12, and overall professionalism.

A deeper look at how to compare suppliers through sample evaluation13

When I compare samples from different suppliers, I do more than check the product itself. I also evaluate how each supplier communicates, documents, packs, and ships the product. These aspects help me identify real professionals.

I start by comparing authenticity. All genuine Stäubli connectors should look identical. If one supplier provides a connector with different markings, different locking force, or unclear packaging, this is a clear warning sign.

Next, I compare documentation. Reliable suppliers send the correct datasheet, certificate of conformity, and batch details. They also provide installation guides. Less reliable suppliers often send incomplete or outdated files. This creates risk during installation and import clearance.

Then I compare communication. Some suppliers reply quickly and answer all questions clearly. Some give vague answers or avoid technical details. When I buy Stäubli connectors, I want a supplier who understands the product well.

Below is a simple comparison checklist I use:

| Evaluation Area | What I Compare | What Good Suppliers Show |

|---|---|---|

| Authenticity | Markings, packaging, part number | Exact match with Stäubli specs |

| Documentation | Datasheets, certificates | Complete and updated |

| Traceability | Batch codes, labels | Clear and verifiable |

| Responsiveness | Reply speed and clarity | Fast and professional |

| Shipping speed | How fast samples arrive | Efficient handling |

| Packaging | Protection and labeling | Clean, well-sealed packaging |

| Price transparency | Clear sample fees | No hidden charges |

| Technical support | Tooling advice, cable guidance | Understands real installation needs |

Comparing multiple suppliers gives me a broader picture. It also shows me who treats the business seriously. Many authorized Chinese distributors and reputable trading companies follow strict quality and documentation rules because they value long-term cooperation.

If I notice that one supplier sends better documentation, communicates more clearly, or provides cleaner packaging, I consider that supplier more reliable. When I choose the right supplier, I avoid problems later when I place bulk orders.

Conclusion

Sample testing gives me confidence and reduces risk before I commit to a larger shipment of genuine Stäubli PV connectors.

-

Explore this link to understand the importance of genuine samples for quality assurance in your projects. ↩

-

Learn about the differences between these models to ensure you choose the right connector for your needs. ↩

-

Discover strategies for developing a comprehensive testing plan that meets your evaluation needs. ↩

-

Understanding the costs of Stäubli PV connector samples can help you budget effectively and avoid unexpected expenses. ↩

-

Learning about sample pricing factors can help you negotiate better terms and make informed decisions. ↩

-

Exploring shipping fee variations can help you choose the best supplier and save on costs. ↩

-

Discovering the significance of small test orders can enhance your purchasing strategy and reduce risks. ↩

-

This resource will guide you on achieving reliable crimping compatibility, crucial for electrical safety. ↩

-

Explore this link to learn comprehensive methods for evaluating Stäubli samples, ensuring safety and performance. ↩

-

Discover detailed specifications and advantages of MC4-Evo2 connectors to make informed decisions for your solar projects. ↩

-

Learn about effective testing methods for environmental resistance to ensure long-lasting connector performance. ↩

-

Exploring documentation accuracy helps you grasp its critical role in ensuring compliance and reducing risks. ↩

-

Understanding sample evaluation can enhance your supplier selection process, ensuring quality and reliability. ↩