Importing Solar Panels from China: Do Low-Wattage Modules Degrade Faster?

Many buyers assume small-power panels are safer, but hidden degradation often appears after installation. That misunderstanding leads to early losses and disappointed customers.

To know if small-power panels are prone to degradation, I focus on materials, test data, usage patterns, and early field performance instead of wattage alone.

When importing custom solar panels from China, I often see buyers relax their checks once the power is low. This is a mistake. Small-power panels can be stable, but only if they are designed, tested, and used correctly. I always treat them with the same seriousness as high-power modules.

How do I test for performance drop1?

Small-power panels may look simple, but performance drop can hide in the first months if testing is weak. I never rely on factory promises alone.

I test performance drop by combining factory flash data, degradation tests, and early field monitoring under real conditions.

Start with factory test data

Every shipment must include flash test reports. I check more than just Pmax.

I look for:

- Power tolerance format (W or %)

- Current and voltage consistency

- Batch distribution, not single samples

If the spread is wide at day one, degradation risk is higher later.

Focus on first-year losses2

Small-power panels often show higher first-year loss due to LID. I pay close attention to this stage.

| Test item | Why it matters |

|---|---|

| LID test result | Predicts early power drop |

| LETID data | Shows cell treatment quality |

| Thermal cycling | Reveals microcrack risk |

| Damp heat test | Indicates moisture resistance |

Panels that lose 2–5% in the first year usually keep degrading faster.

Field testing matters most

Lab tests are controlled. Reality is not.

I install test samples in real conditions and track output for 6–12 months. Early deviation almost always predicts long-term behavior.

From my experience, this step catches more problems than any certificate.

What materials improve stability?

Power level does not decide stability. Materials do. This is where small-power panels often cut corners.

Stable small-power panels use the same cell, encapsulation, and backsheet materials as higher power modules from the same manufacturer.

Cell type matters more than wattage

I see clear patterns:

- Monocrystalline cells degrade slower

- Polycrystalline cells degrade faster

- Thin cells crack more easily

Some low-wattage panels still use older poly cells. This increases annual degradation to 0.8–1.2%.

Encapsulation and lamination

Cheap EVA yellows faster. Weak lamination traps moisture.

| Material | Impact on degradation |

|---|---|

| High-grade EVA3 | Slows UV aging |

| POE encapsulation | Improves PID resistance4 |

| Quality backsheet | Blocks moisture |

| Strong frame design | Reduces microcracks |

If a factory downgrades materials for small panels, lifespan shortens quickly.

Junction box and diodes

Small panels often have compact junction boxes. Heat builds up faster.

I always confirm:

- Diode rating margin

- Heat dissipation design

- Solder quality

Many early failures start here, not in the cells.

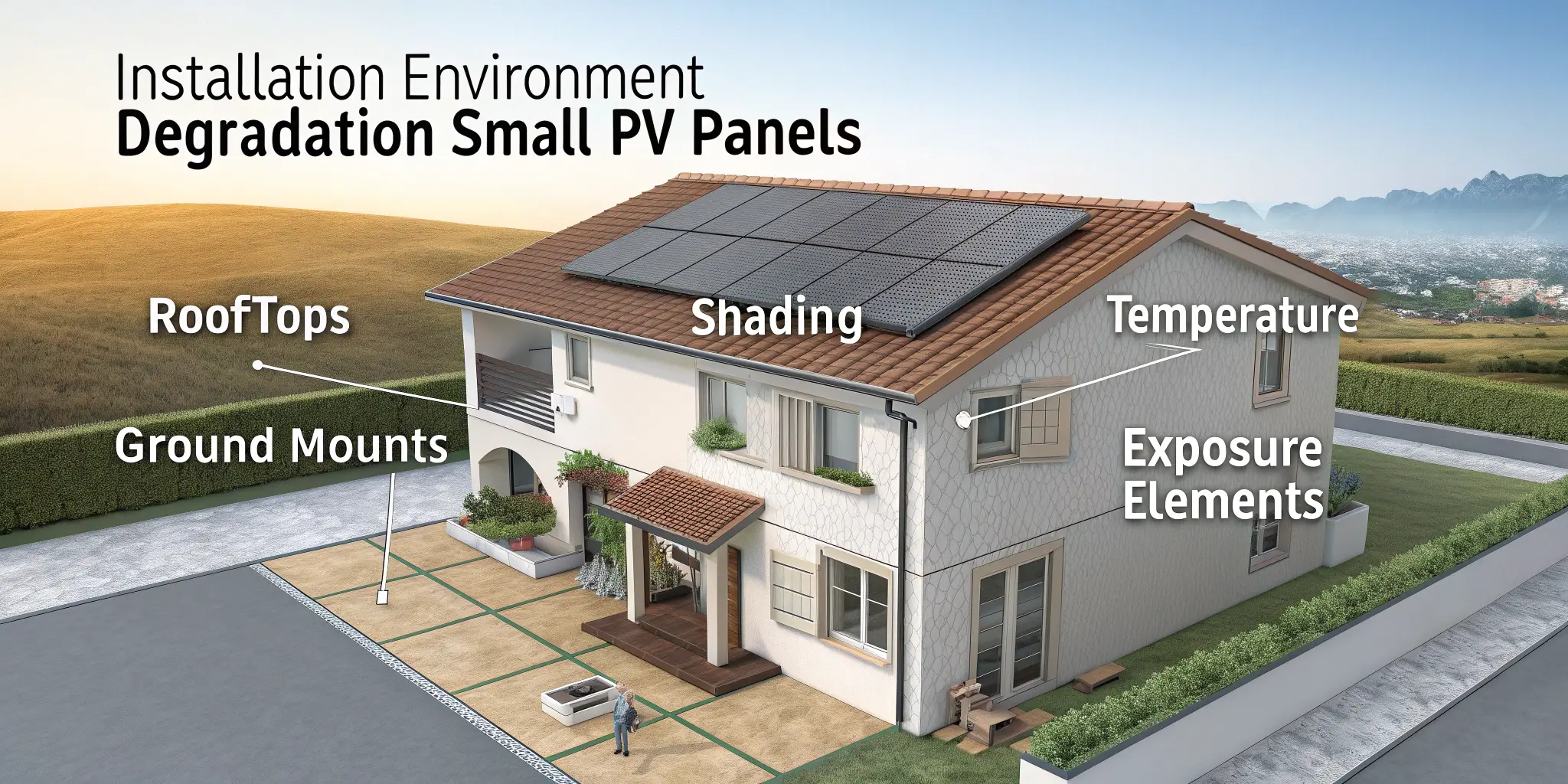

How does usage pattern affect lifespan?

Even a well-made small-power panel degrades faster if used incorrectly. Usage matters more than many buyers realize.

Usage pattern affects lifespan5 through temperature cycling, shading behavior, and electrical loading, even for small-power panels.

Temperature cycling6 is still a risk

Small panels heat up less, but they still expand and contract daily. Thin cells suffer more during cycling.

Frequent on-off operation increases stress. Off-grid and portable systems see this often.

Shading and hotspot risk

Small panels are often installed in complex environments.

- Partial shading

- Irregular tilt

- Mixed orientations

Their bypass diode layout increases hotspot risk under shade. This accelerates degradation.

Load mismatch

I often see small panels connected without proper matching. This causes reverse current stress.

| Usage factor | Effect |

|---|---|

| Partial shading | Hotspots |

| Poor ventilation | Heat buildup |

| Electrical mismatch | Cell stress |

| Frequent cycling | Microcracks |

Good usage design slows degradation more than power size.

How do I mitigate early losses7?

Early losses decide lifetime output. If I control the first two years, the panel usually lasts.

I mitigate early losses by defining stricter specs, improving QC, and monitoring performance8 immediately after installation.

Define tighter specifications

For small-power panels, I never accept vague specs.

I define:

- Positive power tolerance

- LID limit

- Material list in contract

Custom orders allow this if defined early.

Strengthen incoming inspection

I do not rely on supplier QC alone.

| QC step | Purpose |

|---|---|

| Random flash retest | Verify tolerance |

| Visual inspection | Catch cracks |

| EL testing | Detect microcracks |

| Sample aging test | Predict losses |

This reduces surprises.

Monitor early performance

I track output monthly. If deviation appears, I act fast.

Early replacement is cheaper than long-term underperformance.

My rule of thumb

If a small-power panel performs well in the first 12–18 months, it usually stays stable. If it fails early, no warranty can fix the lost energy.

Conclusion

Small-power panels are not automatically safer. Stability depends on materials, testing, usage, and early control, not on wattage alone.

-

Understanding performance drop testing methods can help ensure your solar panels operate efficiently and meet expectations. ↩

-

Exploring first-year losses can provide insights into potential long-term degradation and help in making informed purchasing decisions. ↩

-

Explore how High-grade EVA can significantly enhance the lifespan of solar panels by slowing UV aging. ↩

-

Learn about PID resistance and its crucial role in preventing performance degradation in solar panels. ↩

-

Understanding how usage patterns impact lifespan can help you optimize solar panel performance and longevity. ↩

-

Exploring temperature cycling will provide insights into how thermal stress affects solar panel efficiency and durability. ↩

-

Understanding how to mitigate early losses can significantly enhance the longevity and efficiency of solar panels. ↩

-

Exploring the impact of performance monitoring can provide insights into maintaining optimal solar panel output. ↩