Should Small-Power Solar Applications Use Double-Glass Panels When Importing From China?

Small-power solar panels look simple. Many buyers assume structure does not matter. This mistake often leads to cracks, early failures, and repeated replacements.

From my experience, small-power applications should use double-glass panels only when the environment, lifespan, and maintenance cost justify the added weight and price.

When I source custom solar panels from China, I never decide based on wattage alone. I look at where the panel will live, how long it must last, and how painful failure would be. That is where double-glass really shows its value.

How do double-glass panels1 improve reliability in small-power systems?

Small-power panels are often underestimated. They are smaller, cheaper, and seen as disposable. This mindset creates hidden risks once the panels face real outdoor stress.

Double-glass panels improve reliability by increasing mechanical strength, sealing out moisture, and stabilizing electrical insulation over long periods.

Mechanical strength and microcrack control

Small panels are often mounted on poles, thin frames, or compact brackets. These structures flex more than large rooftop racks. Over time, bending causes microcracks.

Double-glass panels use glass on both sides. This creates a symmetric structure. Stress spreads evenly across the cells. In my projects, this design reduces microcrack risk2 by more than half compared to single-glass panels.

| Structure Type | Resistance to Bending | Microcrack Risk |

|---|---|---|

| Single-glass | Medium | Medium–High |

| Double-glass | High | Low |

This matters even more for small panels because one cracked cell can drop system output fast.

Moisture and corrosion resistance

Many small-power systems work in humid places. Think coastal lighting, roadside cameras, or agricultural sensors. Moisture is the real enemy here.

Single-glass panels rely on a polymer backsheet. Over time, UV and heat age this layer. Moisture enters. Corrosion starts.

Double-glass panels remove this weak point. Glass blocks water vapor far better than any backsheet. This slows corrosion and protects insulation.

Electrical stability and PID prevention

Even small systems can suffer from PID. Poor grounding and floating voltage are common in compact setups.

Double-glass designs improve insulation balance. Ion movement slows down. PID risk drops close to zero in most cases. This is one reason many suppliers now pair double-glass with POE encapsulation.

Are the cost implications worth it for small-power applications?

Price is the first objection I hear. Double-glass panels cost more, and small-power projects are often cost-sensitive.

Double-glass panels cost more upfront, but they often reduce total ownership cost when replacement and downtime are considered.

Upfront price difference

From Chinese factories, the typical difference looks like this:

| Panel Type | Relative Cost |

|---|---|

| Single-glass | Base |

| Double-glass | +20–30% |

This scares many buyers away at first.

Degradation and warranty impact

Single-glass panels usually carry 25-year warranties. Double-glass panels often extend to 30 years.

More important is degradation speed.

| Panel Type | Annual Degradation3 |

|---|---|

| Single-glass | ~0.6–0.7% |

| Double-glass | ~0.4–0.45% |

In small systems, losing even 10% output can break functionality. Think dim lights or unreliable sensors.

Replacement cost reality

Replacing small panels sounds cheap. In reality, it is not.

Labor. Transport. Downtime. Customer complaints.

In remote or distributed systems, one avoided replacement can pay for the double-glass upgrade. This is why I often recommend double-glass for projects expected to run unattended for years.

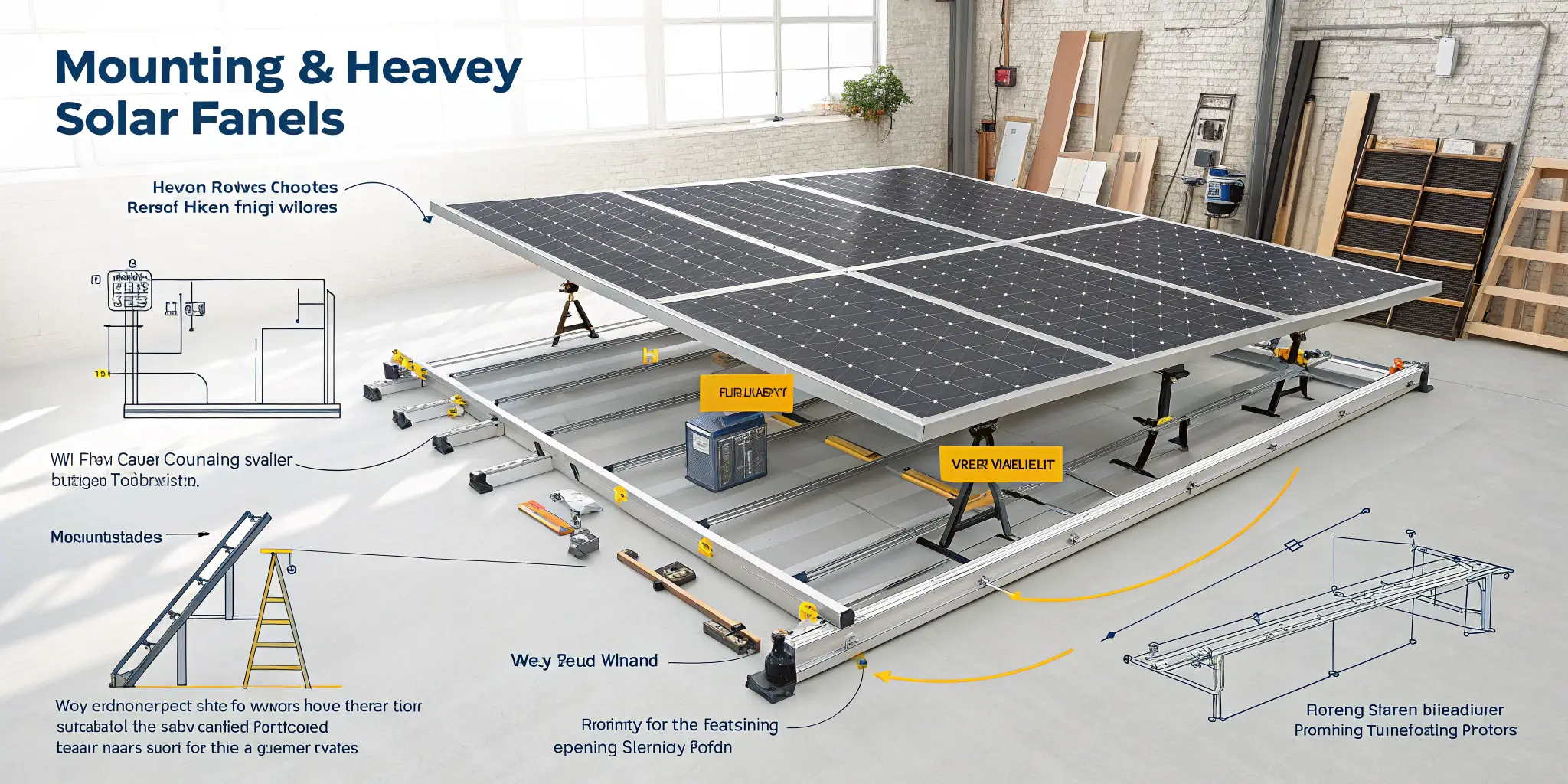

How does added weight affect installation of small-power panels?

Weight is a real concern. Small systems often use light frames and thin brackets.

Double-glass panels add weight4, so mounting strength must be verified early, not after delivery.

Typical weight increase

Double-glass panels add about 15–20 kg per square meter. For small panels, this often means 1–3 kg extra.

That sounds small. But on a pole-mounted system, it matters.

Structural checks I always perform

Before approving double-glass, I check:

- Frame thickness

- Clamp area and pressure

- Wind load rating

- Pole stiffness

If any of these are weak, weight becomes a risk.

Customization to control weight

China factories allow flexibility. I often specify:

- 2.0 + 2.0 mm glass

- Optimized aluminum frames

- Smaller clamp zones with reinforcement

This keeps strength high while limiting weight growth.

| Design Option | Strength | Weight |

|---|---|---|

| Thick glass | High | High |

| Thin glass | High | Medium |

Installation discipline

Double-glass panels demand better installation. Over-tightening clamps can still cause damage. But once installed correctly, they stay stable for years.

When is double-glass unnecessary for small-power projects?

Not every project needs double-glass. Over-specification wastes money.

Double-glass is unnecessary when environmental stress, lifespan expectations, and maintenance risks are low.

Low-stress environments

Single-glass panels work well when systems are:

- Indoors

- Under shelter

- Protected from wind and rain

Examples include indoor monitoring devices or sheltered rooftops.

Short lifespan projects

If the system is designed for three to five years, double-glass rarely makes sense. The payback period is too long.

Ultra-lightweight needs

Portable kits and mobile devices care more about weight than durability. In these cases, single-glass or flexible panels fit better.

Budget-driven mass products

For solar lights or decorative uses, cost often beats longevity. Single-glass panels are acceptable if quality control is stable.

Conclusion

From my experience, double-glass panels are not about size. They are about stress, lifespan, and failure cost. Small-power systems deserve the same structural thinking as large ones.

-

Explore how double-glass panels can significantly improve the durability and performance of solar systems. ↩

-

Understand the impact of microcracks on solar panel efficiency and how to mitigate them. ↩

-

Understanding annual degradation rates is crucial for evaluating solar panel efficiency and long-term investment value. ↩

-

Understanding the impact of double-glass panels on installation can help ensure safety and efficiency in solar projects. ↩