How Do Encapsulation Materials Impact Lifespan When Importing Custom Solar Panels From China?

Many solar panels fail earlier than expected. The reason is often hidden inside. Encapsulation decides whether a panel survives or slowly dies.

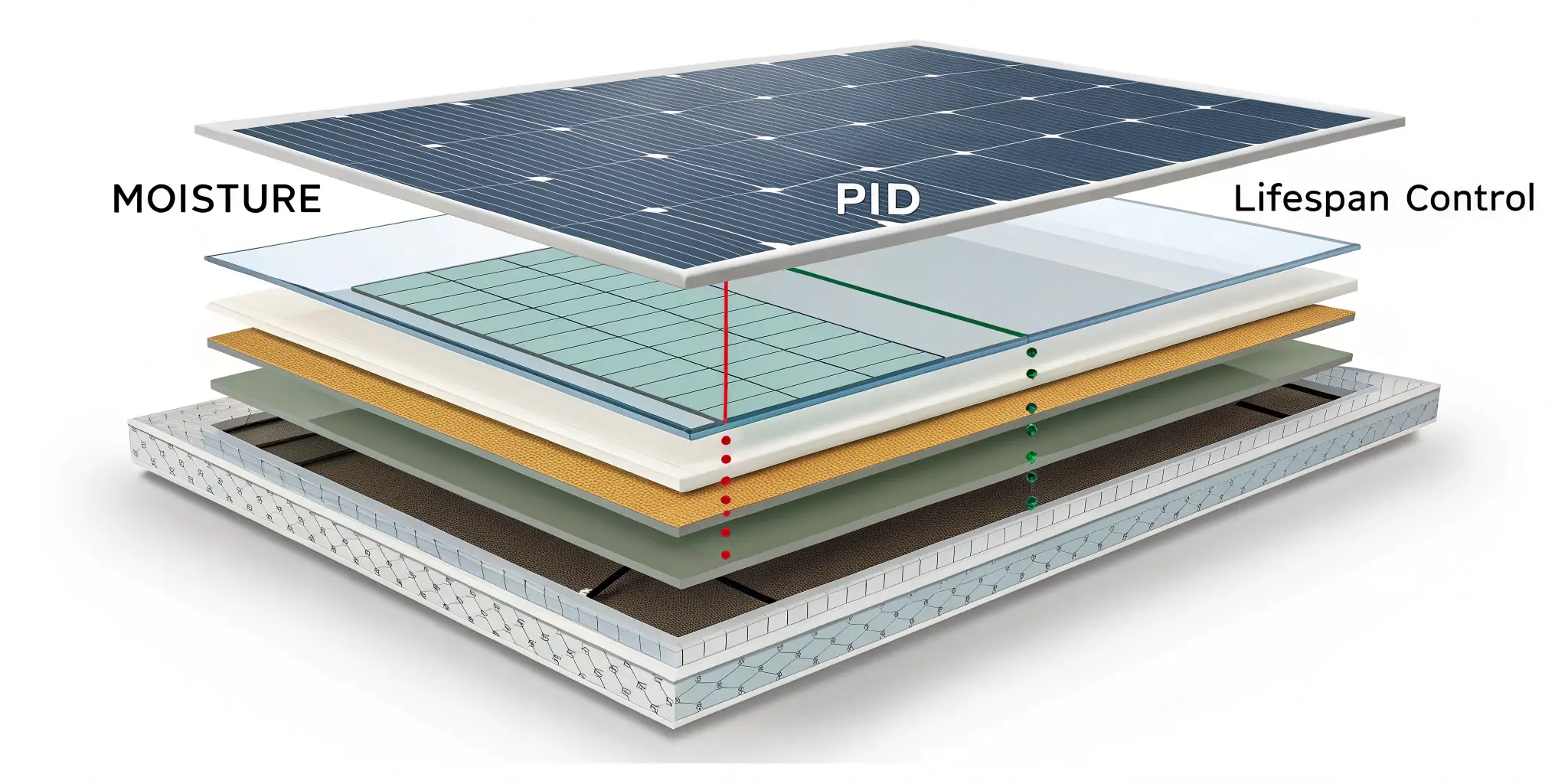

From my experience, encapsulation materials directly control moisture resistance, PID risk, and real lifespan, often more than cell efficiency itself.

I have handled many custom panel projects from China. Some panels looked perfect at delivery but degraded fast. Almost every time, the root cause was encapsulation choice and lamination control. If you ignore this, no warranty will save you.

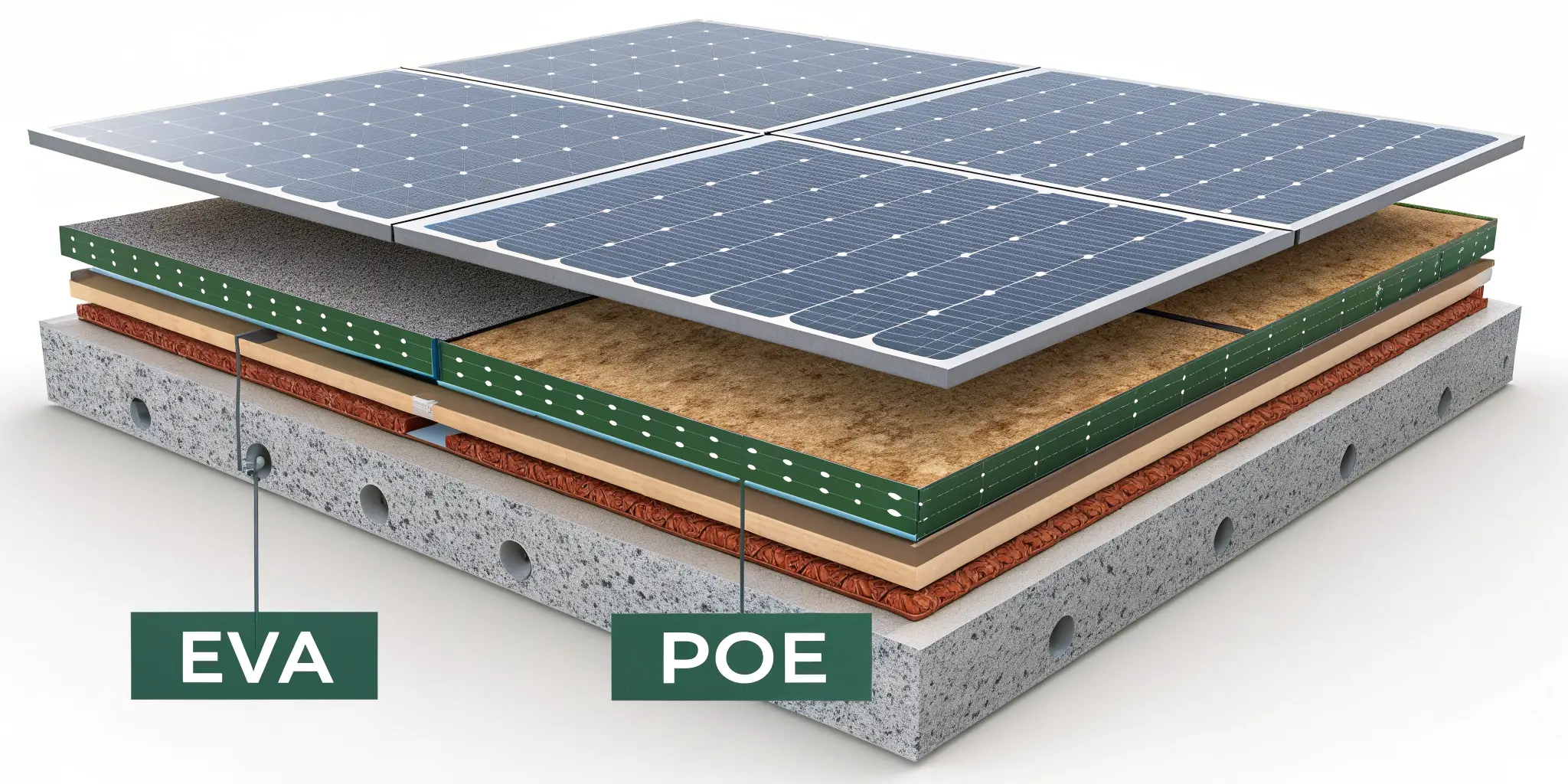

How do EVA and POE compare?

EVA and POE look similar. Their impact on lifespan is very different.

EVA offers lower cost and good adhesion, while POE provides much better moisture and PID resistance1 for long-term reliability.

EVA: the common default

EVA is used in most standard panels. I see it everywhere because it is cheap and easy to process.

Advantages:

- Good adhesion to glass and cells

- Mature lamination process

- Lower material cost

Problems appear over time.

In humid or hot climates, EVA can release acetic acid. This acid corrodes cell fingers and busbars. It also accelerates power loss.

In coastal and tropical projects, I have seen EVA-based panels lose output much faster than expected.

POE: better protection, higher cost

POE behaves differently. It has much lower moisture permeability.

Key benefits:

- Strong PID resistance

- Better electrical insulation

- Lower risk of corrosion

POE does not generate acetic acid. This alone extends panel life by years in harsh environments.

The trade-off is cost and process control. POE needs tighter lamination control. Some factories struggle with this.

Practical comparison table

| Factor | EVA | POE |

|---|---|---|

| Cost | Lower | Higher |

| Moisture resistance | Medium | High |

| PID resistance | Weak to medium | Strong |

| Process tolerance | High | Lower |

| Long-term stability | Medium | High |

My selection rule

For dry and mild climates, EVA can be acceptable.

For humid, coastal, floating, or high-voltage systems, I choose POE.

Encapsulation choice should match environment, not just budget.

What materials resist UV and moisture?

Encapsulation is a system, not a single film.

I evaluate UV resistance2 and moisture barriers3 as a complete stack, not just EVA or POE alone.

UV exposure and yellowing

Poor encapsulants yellow under UV. Yellowing blocks light. Power drops slowly and permanently.

Low-quality EVA can lose 5–10% light transmission over time. This is silent degradation.

I always ask for:

- UV aging test data

- Transmission loss curves

- Long-term field references

Moisture pathways inside panels

Moisture enters from edges and backsheets. Encapsulation must slow this process.

Key materials that matter:

- Encapsulant film

- Backsheet structure

- Edge seal quality

POE slows moisture migration far better than EVA.

Glass-glass structures

For long lifespan projects, I prefer glass-glass modules.

Benefits:

- Lower moisture ingress

- Better mechanical stability

- Reduced encapsulant aging

With dual POE layers, degradation rates drop significantly.

Compatibility between layers

Mismatch causes delamination.

Encapsulant must match:

- Backsheet chemistry

- Glass surface treatment

- Lamination temperature

I have seen good EVA fail because it did not match the backsheet.

Materials checklist I use

- Certified encapsulant brand

- Proven backsheet compatibility

- Stable UV additives

- Controlled thickness

Materials decide how stress, heat, and moisture move inside the panel.

How do I test durability?

Promises mean nothing without tests.

I rely on standardized accelerated aging tests4 to validate encapsulation durability before approving mass production.

Damp heat testing

This is my first filter.

Standard condition:

- 85°C

- 85% humidity

- 1000 hours

Good encapsulation shows no delamination, corrosion, or insulation drop.

For long-life projects, I request extended testing.

UV aging tests

UV destroys weak encapsulants.

I ask for:

- 3000-hour UV exposure data

- Transmission loss under 2%

- No yellowing or cracking

If data is missing, I assume risk.

PID resistance testing5

PID kills output silently.

I require:

- IEC 62804 PID test reports

- Low ion conductivity confirmation

- Clear encapsulant specification

POE performs much better here.

Lamination process verification

Even good material fails with bad lamination.

I audit:

- Lamination temperature curves

- Curing time

- Melt flow index of encapsulant

Poor curing shortens lifespan no matter what film is used.

Test summary table

| Test | What it proves |

|---|---|

| Damp heat | Moisture resistance |

| UV aging | Light stability |

| PID | Electrical insulation |

| Thermal cycling | Layer compatibility |

Testing turns assumptions into evidence.

How do I optimize cost versus reliability?

Encapsulation is where many buyers cut cost. This is risky.

I optimize cost by matching encapsulation grade6 to real risk, not by choosing the cheapest option.

Hidden cost of cheap encapsulation

Cheap EVA saves money upfront. It costs more later.

I have seen:

- Warranty claims

- Reputation damage

- Customer distrust

These costs are invisible during purchase.

Smart cost control strategies

I do not overspec blindly. I segment projects.

For example:

- Indoor or portable panels → standard EVA

- Outdoor humid systems → POE

- Long warranty products → glass-glass + POE

This balances risk and budget.

Contract control matters

I always:

- Lock encapsulant brand and model in BOM

- Prohibit substitutions

- Tie payments to test approval

Without contract control, material quality drifts.

Batch consistency is critical

Even small formulation changes affect lifespan.

I require:

- Same encapsulant batch for one order

- Traceability records

- Factory confirmation

Consistency protects repeat orders.

My final rule

Encapsulation is not a place to gamble. Spend where failure is expensive. Save only where risk is low.

Conclusion

Encapsulation defines real solar panel lifespan. By choosing the right materials, testing durability, and controlling process details, I turn custom panels from China into long-term, reliable products.

-

Exploring PID resistance can help you choose solar panels that maintain efficiency and longevity in challenging environments. ↩

-

Understanding UV resistance is crucial for solar panel longevity. Explore this link to learn about effective materials and their benefits. ↩

-

Moisture barriers are essential for preventing degradation. Discover how they function and their importance in solar technology. ↩

-

Explore this link to understand how accelerated aging tests validate product durability, ensuring reliability in mass production. ↩

-

Learn about PID resistance testing to grasp its importance in maintaining solar panel efficiency and preventing silent output loss. ↩

-

Understanding encapsulation grade is crucial for making informed decisions about cost and reliability in solar panels. ↩