How to Import Solar Panels From China & Check Junction Box IP Ratings?

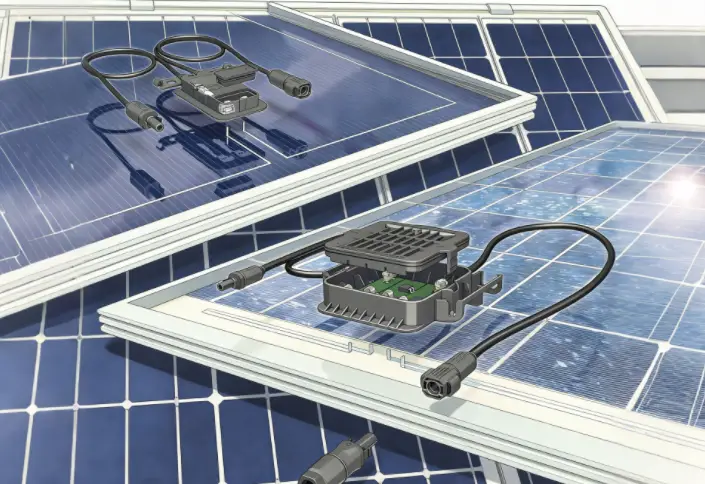

Importing panels without checking junction box protection can cause failures, disputes, and field downtime. I have seen moisture damage and diode faults caused by weak specifications.

I reduce risks by selecting verified manufacturers, defining IP ratings in contracts, validating certifications, and checking waterproof testing before shipment. I also match protection levels to installation environments and long-term reliability goals.

I work with buyers who focus on cells and power output first. I understand this focus. Yet I always treat junction boxes as a reliability gate. I learned this through project work and supplier coordination. So I will explain how I approach protection levels when importing custom panels.

How do I choose IP ratings?

Choosing the wrong IP rating exposes junction boxes to moisture, dust, and corrosion. I have seen systems fail early because protection levels were guessed instead of specified.

I choose IP ratings by matching environmental exposure, installation layout, and system voltage requirements. I treat IP671 as standard, IP682 for harsh sites, and IP65 only for limited use cases.

Understanding IP Rating Structure

I always begin by reviewing what the two digits represent. I keep my decision simple and practical.

| Rating | Dust Protection | Water Protection | Typical Usage |

|---|---|---|---|

| IP65 | Dust tight | Water jets | Indoor or sheltered |

| IP67 | Dust tight | Temporary immersion | Standard rooftop |

| IP68 | Dust tight | Continuous immersion | Harsh climates |

I rarely rely on marketing claims. I compare technical sheets and certification reports3. I check testing duration and depth conditions. I confirm connector installation state during tests.

Matching Protection to Installation Conditions

I evaluate real exposure conditions before selecting a rating. I ask about rain intensity, humidity cycles, and mounting angles. I check cable routing and shading.

For residential rooftops, I normally accept IP67. This level balances cost and protection. For coastal or humid regions, I move toward IP68. I saw corrosion cases in tropical installations. This experience shaped my approach.

Utility installations require more care. I study maintenance intervals and access difficulty. If service visits are expensive, I push for higher protection margins.

Considering Certification and Safety Standards

I align IP decisions with certification frameworks. I always verify compliance with IEC safety standards4. These include insulation distance and ingress validation.

I request supporting documentation before purchase approval. I review test lab identity and report scope. I confirm junction box configuration matches certified structure.

I also add IP requirements directly into technical agreements. I describe current rating and cable specification beside protection level. This method prevents disputes later.

This structured approach allows me to treat IP selection as engineering control rather than assumption.

How do I test waterproofing5?

Assuming protection levels without validation creates risk. I have seen ratings listed in catalogs but unsupported by real testing evidence.

I verify waterproofing by reviewing lab reports6, performing visual inspection, and requesting sample immersion7 or spray testing before mass production approval.

Reviewing Manufacturer Test Documentation

I first review formal ingress testing records. I examine lab accreditation and testing methodology. I confirm testing sequence includes cable assembly.

| Document Type | Purpose |

|---|---|

| Test Report | Validates ingress protection8 |

| Certification Sheet | Confirms compliance |

| Factory QA Record | Shows batch consistency |

I do not accept summary statements alone. I ask for detailed procedure descriptions. I verify testing duration and conditions match expected exposure levels.

Conducting Sample Validation

I usually request pilot samples. I check potting quality and gasket alignment. I examine cable sealing and molding finish.

I sometimes arrange basic verification tests with partners. These include controlled spray exposure or immersion observation. I use these steps to detect obvious sealing weaknesses.

I remember a project where potting bubbles caused micro leakage. Early inspection prevented large order defects. This event strengthened my validation habits.

Checking Assembly Influence

Waterproof performance depends on final assembly. Connector installation affects sealing integrity. Cable strain also impacts protection.

I confirm suppliers test fully assembled configurations. I request photos or videos showing test preparation. I include inspection checkpoints in pre-shipment audits.

These steps help me treat waterproof testing as a process rather than a single certificate review.

Can customization affect protection?

Customization changes enclosure geometry and material selection. I have seen design modifications reduce protection unintentionally.

Customization can improve or weaken protection depending on material choice, potting quality, housing shape, and connector configuration.9 I manage this risk through specification control and prototype evaluation.

Material and Structural Design Influence

I analyze enclosure materials carefully. Plastic composition affects thermal expansion and sealing stability.

| Factor | Impact |

|---|---|

| Polymer grade | Weather durability |

| Housing thickness | Mechanical stability |

| Seal design | Leakage resistance |

I request engineering drawings before approving customization. I compare structure to proven baseline designs. I avoid drastic geometry changes without validation.

Potting and Sealing Adjustments

Customization often changes potting volume or curing method. I evaluate resin type and application control.

I once encountered under-filled potting cavities in modified boxes. That experience showed me how small process changes influence reliability. Since then I request process descriptions.

I also verify sealing surfaces and cable glands. I confirm torque recommendations and gasket compression limits. These details affect real protection.

Contract Specification Control

I treat customization risk through documentation.10 I list IP rating, current rating, and certification scope in agreements.

I also specify validation testing before full production. I include acceptance criteria and inspection checkpoints.

This approach keeps customization aligned with protection objectives. It also helps suppliers understand expectations clearly.

What common failures occur?

Ignoring junction box weaknesses leads to long-term reliability issues. I have seen failures appear years after installation.

Common failures include seal degradation11, diode overheating, corrosion, and potting defects. These problems often result from mismatched IP levels or weak manufacturing controls.

Environmental Degradation

Exposure to temperature cycles stresses materials. Seal elasticity decreases over time.

| Failure Mode | Cause |

|---|---|

| Moisture ingress | Seal aging |

| Corrosion | Salt exposure |

| Housing cracks | UV stress |

I examine environmental durability reports when selecting suppliers. I review aging test results. I compare material stability claims.

Electrical and Thermal Stress

IP rating does not ensure heat tolerance. Diode operation generates thermal load. Poor heat handling leads to failure.

I analyze current ratings and thermal dissipation design. I compare diode mounting configuration. I inspect internal layout through sample teardown.

This evaluation helps me link protection design with electrical reliability.

Manufacturing Quality Issues

Production errors frequently cause early failures. Poor potting control or sealing misalignment create hidden defects.

I use factory audits and inspection sampling. I check curing consistency and visual finish. I review process records.

I learned from past sourcing work that manufacturing discipline directly affects field reliability. I use this understanding in supplier selection.

Conclusion

I manage junction box protection through IP selection, validation testing, controlled customization, and failure awareness to protect system reliability and reduce import risks.

-

Explore this link to understand the significance of IP67 ratings and how they can protect your installations effectively. ↩

-

Discover the advantages of IP68 ratings for harsh environments and how they ensure long-lasting performance. ↩

-

Gain insights on interpreting technical sheets and certification reports to make informed decisions on IP ratings. ↩

-

Learn about IEC safety standards to ensure compliance and safety in your electrical projects. ↩

-

Explore this resource to understand various effective methods for testing waterproofing, ensuring reliable results. ↩

-

This link will guide you on how to read and understand lab reports, crucial for validating waterproofing claims. ↩

-

Learn about sample immersion testing, a key method for assessing waterproof integrity before production. ↩

-

Discover the importance of ingress protection ratings and the testing methods that validate them. ↩

-

Understanding the impact of customization on protection can help you make informed design choices and avoid potential pitfalls. ↩

-

Exploring best practices can enhance your approach to managing risks associated with customization, ensuring better project outcomes. ↩

-

Understanding seal degradation is crucial for ensuring the longevity and reliability of solar panels. Explore this link for in-depth insights. ↩