How to Customize Junction Box Location When Importing Solar Panels From China?

Junction boxes look like a small detail. Many buyers ignore them. Later, installers struggle, cables bend, water enters, and failures appear earlier than expected.

From my experience, customizing junction box location is one of the easiest ways to improve installation safety and long-term reliability, if it is specified clearly and tested properly.

When I work with Chinese factories on custom panels, junction box location is always on my checklist. It affects wiring, heat, waterproofing, and even fire safety. Ignoring it usually creates avoidable problems.

How does junction box placement1 affect installation?

Installers feel junction box decisions first. A poor location turns a simple job into a frustrating one.

Poor placement slows installation, increases cable stress, and raises the risk of long-term failure.

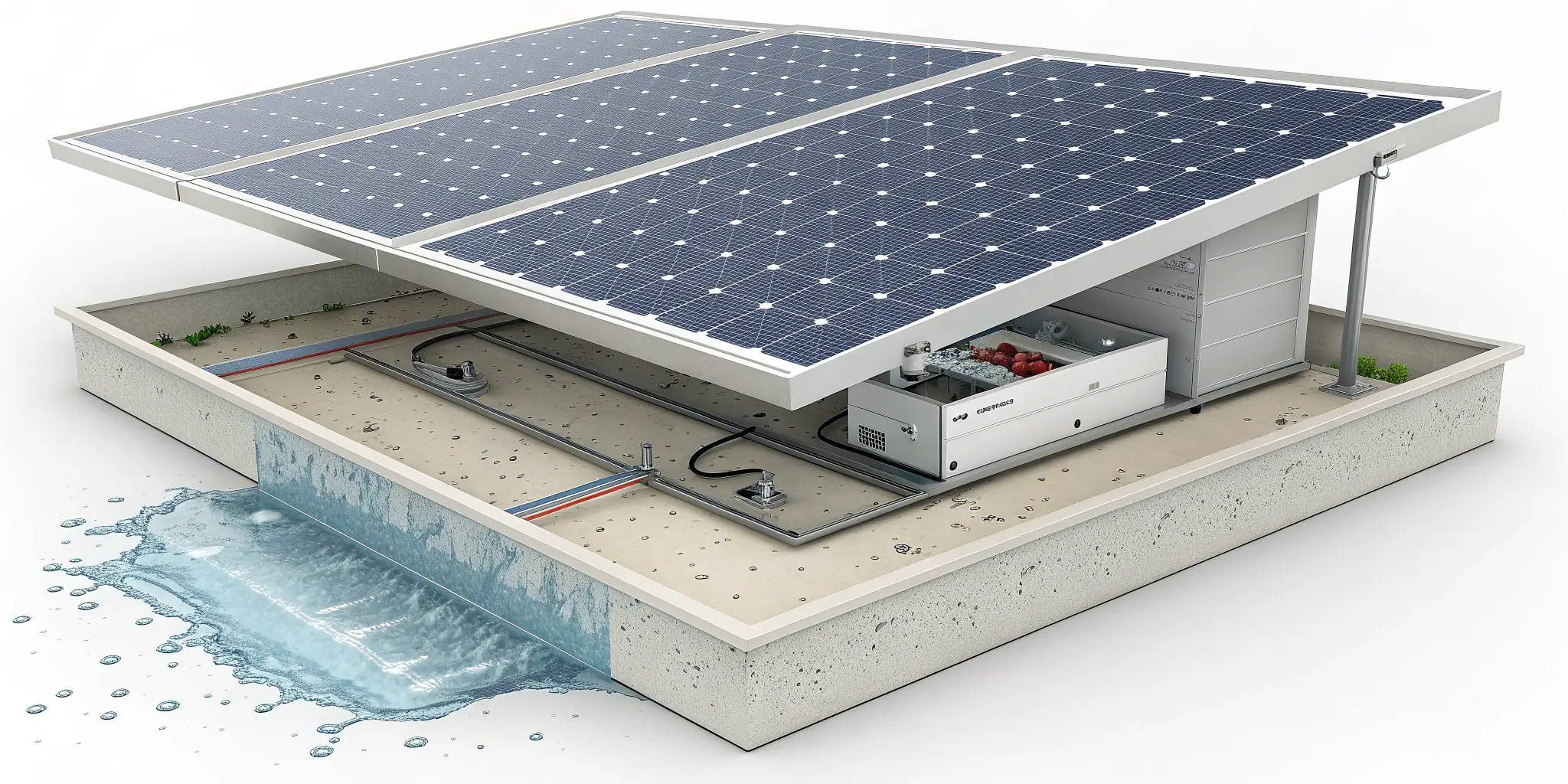

[^2] and junction box layout diagram, PV system wiring solution](https://rayenrg.com/wp-content/uploads/2026/02/installation-impact-2.webp)

Cable routing and bending radius

The junction box defines where cables exit. If the box is too close to the frame edge, cables bend sharply.

Sharp bends damage insulation over time.

I always check that the cable exit allows a smooth bend radius that matches the cable standard.

| Placement Issue | Installation Impact | Long-Term Risk |

|---|---|---|

| Too close to edge | Hard cable routing | Insulation fatigue |

| Centered properly | Easy routing | Low |

Compatibility with mounting systems

Many small-power systems use custom brackets or enclosures. A badly placed junction box can clash with rails or clamps.

This leads to forced adjustments on site. Installers may press against the box without realizing it.

That pressure transfers directly to the backsheet or glass.

Installation time and labor cost

Even small delays multiply across projects.

In my experience, a well-placed junction box can cut installation time by 10–20%. This matters in distributed systems with many small panels.

Can repositioning the junction box2 improve safety?

Yes. Safety is the strongest reason to customize junction box location.

Proper junction box placement reduces fire risk, overheating, and water ingress.

Thermal management

Junction boxes contain bypass diodes. These generate heat.

If the box sits above active cell areas, heat accumulates. This creates hotspots and accelerates aging.

I prefer placing the junction box over neutral zones, away from dense cell strings.

Fire and electrical safety

In compact systems, wiring is often tight. A poor junction box location increases stress on solder joints and diode connections.

Over time, this raises fire risk.

I always request:

- Certified IP68 junction boxes

- UL or IEC fire rating confirmation

- Post-lamination electrical testing

Water pooling and drainage

Panel tilt matters. A junction box placed too low can trap water behind it.

Water pooling attacks seals first.

To avoid this, I specify a minimum height above the backsheet and clear drainage paths.

How do I communicate exact junction box location to Chinese suppliers?

Clear communication prevents 90% of mistakes.

Suppliers need exact coordinates3, not vague descriptions.

[^5] of solar panel array and rear junction box components](https://rayenrg.com/wp-content/uploads/2026/02/technical-drawing-4.webp)

Technical drawings with coordinates

I always submit a drawing that shows:

- Distance from panel edges

- Junction box center point

- Cable exit direction

Words alone are not enough.

| Requirement | Why It Matters |

|---|---|

| X/Y coordinates | Prevent misplacement |

| Tolerance ±2mm | Fit automated lines |

| Orientation arrows | Avoid cable clashes |

Lock details in the BOM

I list:

- Junction box brand and model

- IP rating

- Diode rating

This prevents silent substitutions during production.

Prototype approval before mass production

For custom junction box locations, I always request a prototype.

I check:

- Visual placement

- Cable routing

- Thermal image under load

This step costs time, but saves batches.

What common mistakes affect performance after customization?

Most problems come from shortcuts.

Small mistakes at the junction box quietly reduce performance over time.

Ignoring lamination constraints

Moving the junction box changes internal cable paths. If this is not planned, cables may press against cell busbars.

This creates hidden stress points.

I always confirm the factory has tooling that supports the new location without interference.

Poor sealing after relocation

Custom positions require new sealing steps.

If sealing quality drops, IP rating4 drops with it.

I require sealing process confirmation and random water ingress testing.

Forgetting system-level compatibility

Some buyers focus only on the panel. They forget the enclosure, conduit, or inverter layout.

I always match junction box location to:

- Enclosure cable entry

- Conduit direction

- Vibration exposure

This reduces strain and improves durability.

Conclusion

From my experience, junction box customization is not cosmetic. It directly affects installation speed, safety, and lifespan. When importing custom panels from China, clear drawings and strict testing make all the difference.

-

Understanding junction box placement can significantly enhance installation efficiency and reduce long-term risks. ↩

-

Understanding junction box placement can significantly enhance electrical safety and reduce risks of fire and overheating. ↩

-

Understanding how to communicate exact coordinates can significantly reduce errors in production. ↩

-

Exploring IP ratings helps ensure your solar setup is protected against environmental factors, enhancing longevity. ↩