What types of solar panels can Stäubli PV connectors from China be used with?

When I talk with customers importing solar connectors from China, one of the most common questions I hear is:

“Can Stäubli MC4 connectors be used with all types of solar panels?”

The short answer is yes—as long as they are genuine and properly matched to your panel’s voltage, current, and cable specifications.

Let’s take a closer look at how Stäubli PV connectors fit across different panel technologies and what you should know before buying.

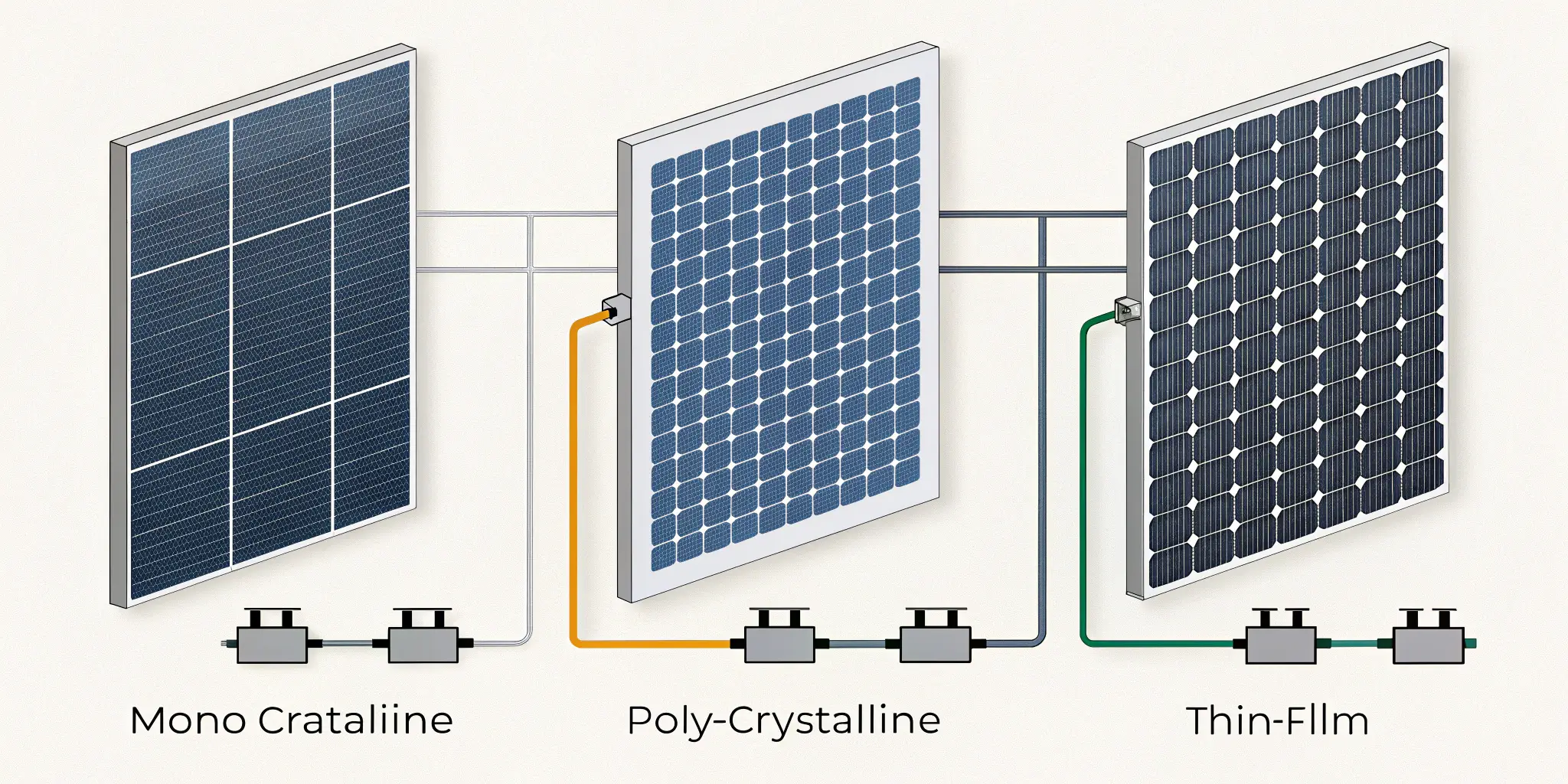

Can I use Stäubli connectors for monocrystalline and polycrystalline panels?

Absolutely.

Stäubli MC4 and MC4-Evo2 connectors1 are compatible with almost all monocrystalline and polycrystalline solar panels made after 2011. These panels typically come with factory-installed MC4 connectors on the output leads, making Stäubli connectors the industry standard for safe and low-resistance interconnections.

| Connector Model | System Voltage | Suitable for Panels | Cable Size | Typical Application |

|---|---|---|---|---|

| MC4 | 1000V DC | Mono & Poly panels | 4–6 mm² | Rooftop or small commercial |

| MC4-Evo2 | 1500V DC | High-power Mono & Poly | 4–10 mm² | Utility-scale or solar farm |

| MC4-Evo 2000 | 2000V DC (emerging) | Next-gen panels | 6–10 mm² | Large-scale utility projects |

I often recommend MC4 for residential systems (up to 1000V) and MC4-Evo2 for larger projects (up to 1500V).

Both options deliver excellent long-term reliability through Stäubli’s patented MULTILAM contact technology2, which ensures minimal resistance and heat buildup.

Are they suitable for bifacial or thin-film panels?

Yes — with the right configuration.

🔹 Bifacial panels

Stäubli connectors are widely used with bifacial solar panels, especially in utility-scale installations. These panels operate at higher power and current levels, so MC4-Evo2 connectors are generally preferred due to their 1500V voltage rating and support for 10 mm² cables.

🔹 Thin-film panels

Thin-film panels (like CdTe or CIGS types) can also use Stäubli connectors, but compatibility depends on the module manufacturer’s junction box design.

You must ensure the panel’s lead cables and connector housings are factory-matched to the Stäubli model3. Some thin-film panels use alternative connector systems, so double-check the panel datasheet or consult your installer.

| Panel Type | Recommended Connector | Voltage Rating | Notes |

|---|---|---|---|

| Monocrystalline | MC4 / MC4-Evo2 | 1000V–1500V | Most common use |

| Polycrystalline | MC4 / MC4-Evo2 | 1000V–1500V | Standard legacy systems |

| Bifacial | MC4-Evo2 | 1500V | High-current strings |

| Thin-film | MC4 or custom | 600V–1500V | Confirm junction box type |

How do I match connector current ratings with my panels?

This is where many importers make mistakes.

You need to match the connector’s rated current4 with your panel’s short-circuit current (Isc) and string current to avoid overheating.

For example:

- If your panel’s Isc = 12A and you plan to connect 10 modules in series, each connector in the string must safely carry that same current.

- Stäubli MC4 connectors typically handle up to 30–35A, while MC4-Evo2 can handle up to 45A depending on cable cross-section.

| Cable Cross-Section | Connector Series | Max Current (A) | Typical Panel Power |

|---|---|---|---|

| 4 mm² | MC4 | 30 A | ≤ 450 W |

| 6 mm² | MC4 or MC4-Evo2 | 35–38 A | 450–550 W |

| 10 mm² | MC4-Evo2 | 45 A | ≥ 550 W (bifacial / TOPCon) |

If you’re importing from China, make sure your supplier can specify the exact part number and current rating. Many local vendors use “MC4-compatible” labeling without stating whether the connector is 30A or 45A rated — a red flag for serious buyers.

What happens if the connector and panel ratings don’t match?

Using mismatched connectors can cause serious performance and safety problems5:

- Overheating and Melting – If the connector’s current rating is lower than the module’s output, the contact points heat up and can melt under load.

- Voltage Breakdown – Exceeding the connector’s rated voltage (e.g., using 1000V MC4s in a 1500V system) can cause insulation failure and arcing.

- System Inefficiency6 – High contact resistance reduces overall power output.

- Warranty Voids – Manufacturers can reject warranty claims if third-party connectors are used or cross-mated with non-Stäubli parts.

Real-world advice

In Australia and Canada, I’ve seen installers replace dozens of burned connectors simply because the imported versions weren’t properly rated or crimped.

That’s why it’s crucial to verify:

- Voltage and current ratings match your modules

- Same-brand connectors are used across the system

- Proper crimping tools are used during assembly

My practical tips for importers

When sourcing Stäubli PV connectors7 from China:

- Use official datasheets – Always refer to Stäubli’s catalog to confirm the exact model and voltage class.

- Match your module specs – Ask your panel supplier which connector type they use (MC4 or MC4-Evo2).

- Avoid cross-mating – Never mix connectors from different brands or series in one string.

- Inspect markings – Genuine Stäubli parts have embossed logos, part numbers, and batch codes.

- Request testing certificates8 – Verify IP rating, salt-mist, and UV aging test reports.

These steps ensure your connectors perform reliably, maintain certification compliance, and avoid post-installation failures.

Conclusion

Stäubli PV connectors from China can safely be used with monocrystalline, polycrystalline, bifacial, and even some thin-film solar panels—but only when properly matched to the system voltage, current, and cable size.

Their MC4 and MC4-Evo2 models remain the global benchmark for safe, low-resistance connections in both residential and utility-scale systems.

If you’re importing for large projects, I recommend confirming your panel’s factory connector type and selecting the correct Stäubli series accordingly. That small step will protect both your investment and your system’s long-term performance.

-

Explore this link to understand the applications and benefits of Stäubli connectors in solar energy systems. ↩

-

Learn about MULTILAM contact technology to see how it enhances reliability and performance in electrical connections. ↩

-

Learn why factory-matching is crucial for optimal performance and safety in solar panel installations. ↩

-

Understanding the connector's rated current is crucial for ensuring safety and efficiency in solar panel installations. ↩

-

Understanding these issues can help prevent costly mistakes and ensure safe installations. ↩

-

Exploring this topic can reveal ways to optimize your solar system's performance and energy output. ↩

-

Explore this link to understand the specifications and benefits of Stäubli PV connectors for your projects. ↩

-

Learn why testing certificates are crucial for ensuring the reliability and safety of electrical components. ↩