Are all MC4 connectors compatible with Stäubli MC4 connectors?

Many buyers believe all MC4 connectors can fit each other. This idea sounds simple, but it often leads to system failures, water leakage, and even fire risks. So this worry is real and common.

Not all MC4 connectors are compatible with Stäubli MC4 connectors. Stäubli connectors use unique mechanical tolerances, pins, and sealing structures. Only Stäubli-to-Stäubli mating ensures the correct fit, stable contact, and long-term safety.

When I work with installers, distributors, or EPC teams, I see how often cross-mating happens on sites. Most people only check the shape, but they ignore the internal design. That is why many failures happen after installation. So in this article, I explain how to check compatibility, what risks come from mixing brands, and how to avoid connection failures.

How do I check connector compatibility?

Many people think compatibility is based on appearance. They see the same MC4 shape and assume it is fine. But MC4 connectors1 from different suppliers have different tolerances and different pin structures. I often see installers push the connectors together and think the “click” indicates a proper fit. But a click does not mean good contact or proper sealing.

Real compatibility depends on contact geometry, waterproof design2, mating force, and locking accuracy3. These small details decide if the connector stays stable under heat, vibration, UV, or rain.

When I check compatibility for buyers, I follow a simple and repeatable method. This method helps me identify gaps that are not visible to the eye. Most cross-mated connectors fail these basic checks, which shows why compatibility is such a big issue.

How I break down MC4 compatibility checks

I normally use four simple steps to test compatibility. Each step matters because Stäubli relies on precise engineering. Even small differences in diameter or pin tension can cause weak contact.

| Step | What I Check | Why It Matters |

|---|---|---|

| Mechanical Fit | Mating force, locking, rotation stability | Loose parts cause heat and arcing |

| Pin Interface | Contact pressure, shape, machining | Wrong pressure increases resistance |

| Seal Integrity | O-ring compression, waterproof performance | Prevents moisture ingress |

| Material Quality | Housing material, UV grade, durability | Low-grade plastics crack faster |

In real cases, I often see these issues:

- The male pin does not fully engage with the female socket.

- The O-ring does not compress enough to reach IP68 sealing.

- The locking fingers do not align, which creates “half-mated” positions.

- The connector can rotate too freely, a clear sign of mismatch.

All these problems happen even though the connectors “look the same.” That is why checking compatibility is not optional. It must be done before installation.

Can I mix brands in one system?

When installers ask me if they can mix connector brands, I always give the same answer: no, you should not mix any MC4 connector brand4 with Stäubli.

The reason is simple. MC4 is not a standard product from a single manufacturer. Many companies copy the appearance, but they do not follow the same design tolerances. Stäubli’s tolerances are extremely precise, and that precision is what ensures stable current flow and long-term safety.

When different brands are mixed, the contact pressure5 becomes unpredictable. This leads to unstable resistance, overheating, and long-term degradation.

I remember a case from an Australian solar farm. The team mixed non-Stäubli MC4 connectors with genuine Stäubli connectors6 during installation because the installers ran out of stock. After six months, they found several connectors discolored, swollen, and partially melted. The cause was clear: mixed connectors created high resistance points. That failure cost them weeks of repairs and a lot of downtime.

Why mixing brands is dangerous

Below is a breakdown of the main issues caused by mixing MC4 brands:

| Risk Area | What Happens | Real Impact |

|---|---|---|

| Contact Resistance | Poor pressure and unstable mating | Hotspots and potential fire |

| Waterproof Rating | O-rings fail to seal properly | Water enters and corrodes pins |

| Mechanical Lock | Locking tabs do not align | Connectors separate under load |

| Certification | System approvals become invalid | Warranty claims may be rejected |

| Long-term Ageing | UV and heat affect plastics differently | Cracks, loosened seals |

Standards like IEC 625487 and UL 6703 clearly warn against mixing connector brands. They state that connectors must come from the same manufacturer and product family. This rule exists because cross-mating was proven to cause failures in many countries.

I always tell buyers one thing: the PV system will run for 25 years. Mixing connectors saves a few dollars today but risks the entire system in the long run.

Are there risks with non-Stäubli connectors8?

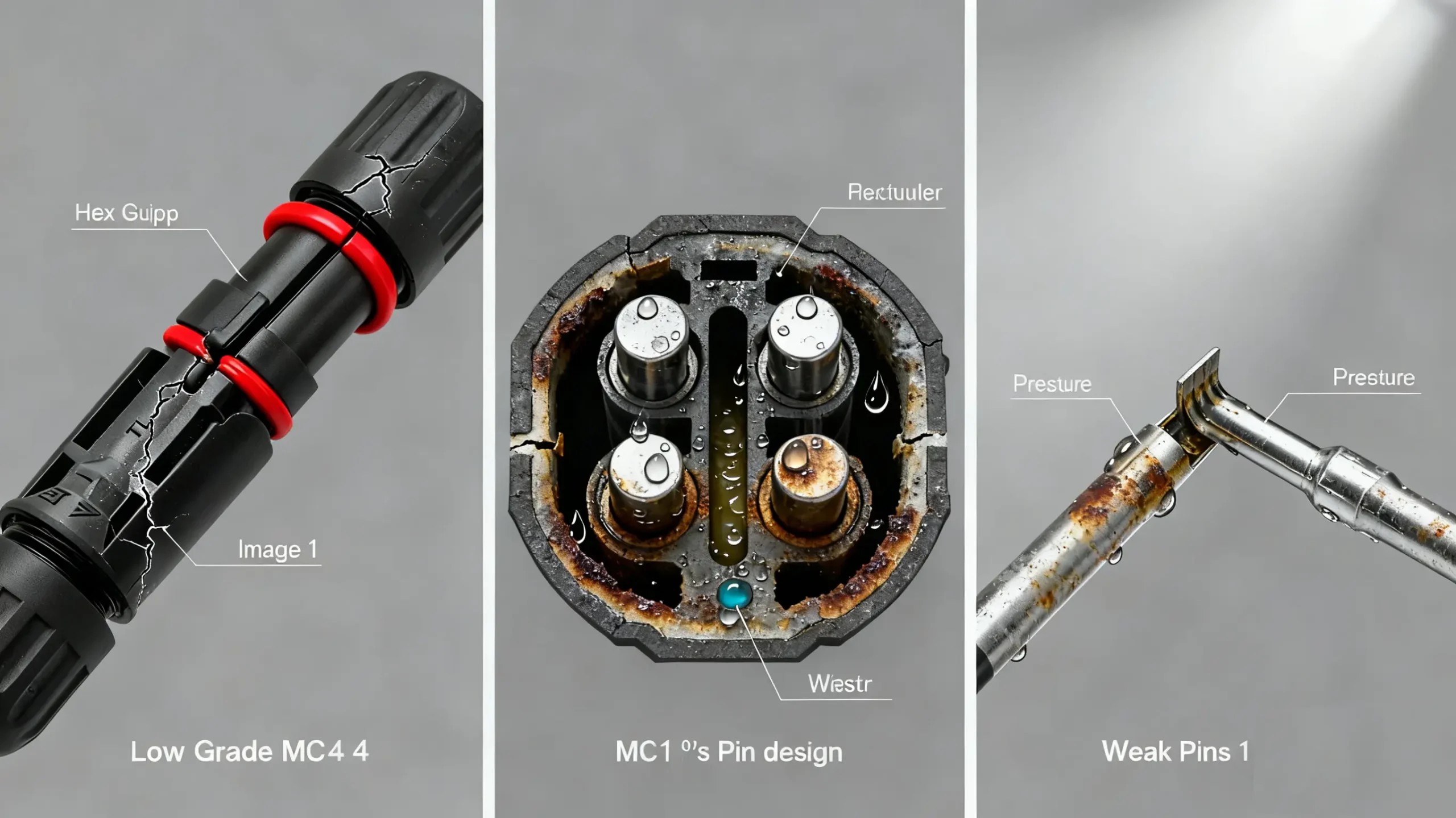

Yes, there are many risks. Many connectors labeled “MC4 compatible” only share the MC4 shape, not the real engineering. These connectors often use lower-grade materials, weaker pins, and softer housings. They may work for the first few months, but they degrade fast under full outdoor exposure.

I see this problem often in developing markets. Many low-priced connectors look similar but fail quickly. They crack under UV, lose tension under heat, or allow moisture to enter after a few rainy seasons. The problem is not always obvious at the start. But over time, failures appear on large numbers of strings.

When buyers ask me why their connectors fail earlier than expected, the cause is almost always the same: they mixed Stäubli with non-Stäubli, or they bought low-grade MC4 connectors9 that only copied the outer shape.

What problems do non-Stäubli connectors create?

Here is a clear breakdown of the risks:

| Issue | What Causes It | Result |

|---|---|---|

| Overheating | Weak pin pressure | Burn marks and connector failure |

| Water Ingress | Poor O-ring compression | Corrosion and intermittent faults |

| Material Degradation | Low-grade plastic | Cracking and insulation loss |

| High Resistance | Unstable contact surfaces | Power loss and inverter faults |

| Unknown Tolerances | Inconsistent dimensions | Loose mating and arcing |

I remember checking a batch of non-Stäubli connectors from a new supplier. The pins looked similar, but they were much softer. After a simple pull test, several pins bent. When I tested resistance, the reading jumped far above normal. This is the danger that buyers do not see until it is too late.

Using non-Stäubli connectors with Stäubli parts does not only reduce system performance—it can create fire risks. This is why EPC companies and utility-scale projects require genuine Stäubli connectors across the whole system.

How do I avoid connection failures?

I learned that connection failures always come from two sources: wrong connector choice or wrong installation practice. Both are preventable. Most issues happen because buyers trust appearance instead of engineering. Connectors look simple, but the internal structure determines 25 years of performance.

So the safest method is to use only genuine Stäubli connectors10 across the entire system. This gives consistent mechanical fit, correct pin geometry, stable contact resistance, and long-term sealing.

When I support customers, I teach them a simple rule: one brand, one model, one system11. This rule removes 90% of the failure risks. If a project starts with Stäubli MC4, it must continue with Stäubli MC4. If a project starts with MC4-Evo2, the entire system must use the same version.

My checklist to prevent connection failure

Here is the checklist I use for every project:

| Check | What I Do | Why It Works |

|---|---|---|

| Brand Consistency | Use only Stäubli | Ensures proper mating and sealing |

| Model Consistency | Use MC4 with MC4, Evo2 with Evo2 | Prevents mismatch in tolerances |

| Pre-Crimp Check12 | Ensure correct die for pins | Avoids weak crimps |

| Post-Crimp Pull Test13 | Test mechanical strength | Ensures stable current flow |

| Visual Seal Check | Confirm O-ring sits correctly | Prevents moisture ingress |

| Final Torque Check | Tighten caps properly | Ensures long-term stability |

Good installation practice is just as important as choosing the right connectors. Even the best connector fails if it is crimped poorly, left exposed, or not seated fully. I always tell installers: “push until the click, but also pull lightly to confirm the lock.”

This simple habit prevents many half-mated failures, which are common on solar farms.

Conclusion

Only Stäubli connectors are fully compatible with Stäubli connectors, so using one brand and one model across the whole system is the safest and most reliable choice.

-

Understanding MC4 connectors is crucial for ensuring proper solar panel connections and avoiding installation issues. ↩

-

Exploring waterproof design can help you understand its importance in preventing moisture ingress and ensuring longevity. ↩

-

Learning about locking accuracy can prevent connection failures and enhance the reliability of your installations. ↩

-

Understanding the risks of mixing MC4 connector brands can help ensure the safety and longevity of your solar installation. ↩

-

Learn how contact pressure impacts electrical connections and why maintaining it is crucial for system safety. ↩

-

Explore why Stäubli connectors are favored for their precision and reliability in solar systems, ensuring optimal performance. ↩

-

Discover the standards set by IEC 62548 regarding connector use to ensure compliance and safety in installations. ↩

-

Understanding the risks of non-Stäubli connectors can help you make informed decisions and avoid costly failures. ↩

-

Exploring the risks of low-grade MC4 connectors can protect your investment and ensure long-term reliability. ↩

-

Explore the advantages of genuine Stäubli connectors for reliable performance and longevity in your projects. ↩

-

Learn how this rule can significantly reduce connection failure risks in your installations. ↩

-

Understand the significance of a Pre-Crimp Check to ensure strong and reliable connections. ↩

-

Discover the best practices for conducting a Post-Crimp Pull Test to ensure mechanical strength. ↩