Why Does Stäubli Offer Both U-Type and O-Type Terminals for Their MC4 Connectors?

Many solar installers struggle to understand why Stäubli offers two types of MC4 terminals. One is open-ended, the other is closed—but both serve different installation needs.

Stäubli offers both U-type and O-type MC4 terminals to meet different requirements in field installations and automated production lines.

If you're confused about which pin design to choose, don’t worry. I’ve broken it down based on safety, compatibility, and real-world use.

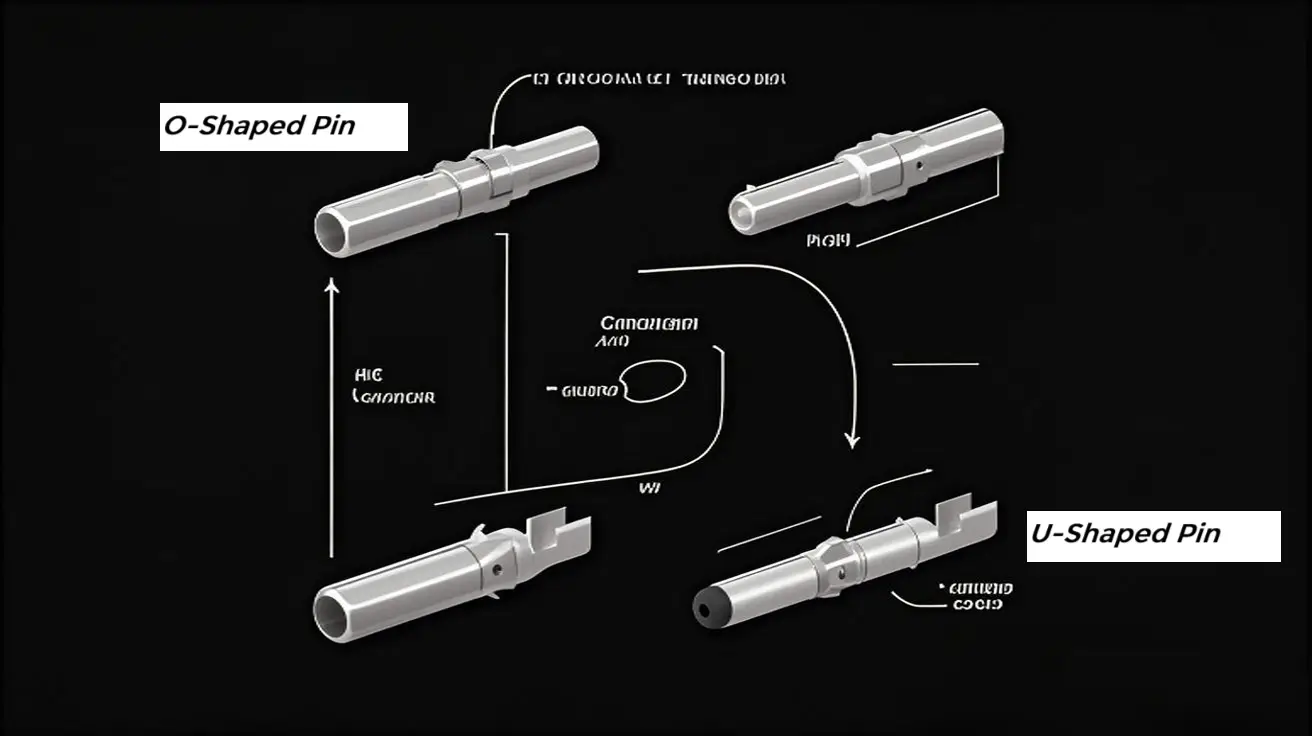

What’s the Functional Difference Between U-Type and O-Type MC4 Terminals?

Choosing the wrong terminal shape could lead to loose connections or even failed certification tests.

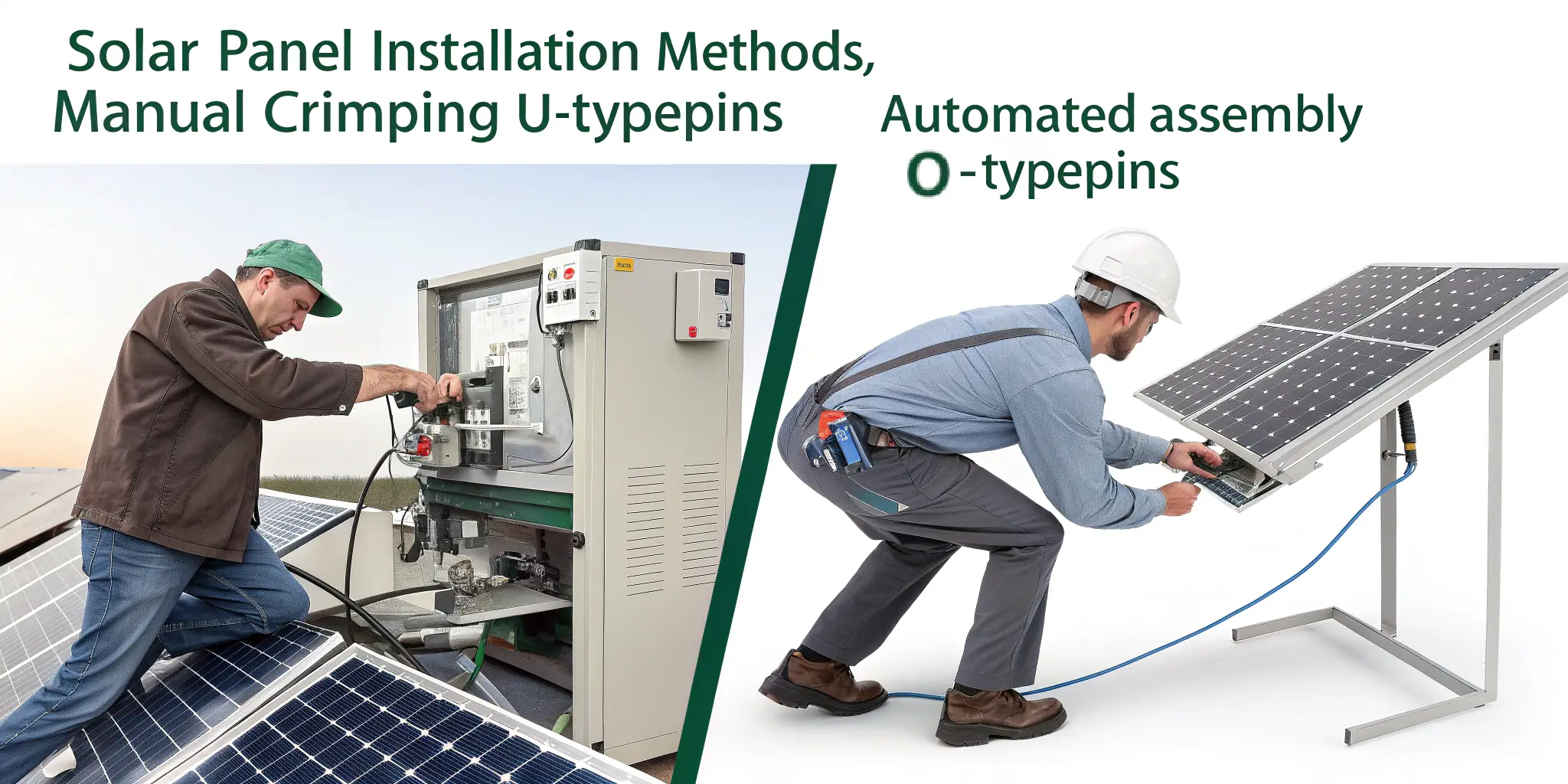

U-type MC4 terminals1 are crimped manually on-site, while O-type terminals2 are pre-crimped and used in automated production.

Dive Deeper: U vs O Explained

| Feature | U-Type Terminal | O-Type Terminal |

|---|---|---|

| Shape | U-shaped (open barrel) | O-shaped (closed barrel) |

| Crimping Method | Manual, on-site | Automated, factory crimped |

| Installation Use | Field-installations | OEM/pre-assembled strings |

| Risk of Error | Higher, if tools are poor | Lower, factory-controlled |

| Repair Flexibility | High (can redo crimp) | Low (usually sealed units) |

I usually recommend U-type for projects where custom cable lengths are needed or in retrofit jobs. O-type is ideal for mass production lines where every string is identical and speed is critical.

Why Does Multilam Contact Technology Support Both Pin Designs?

You might wonder why Stäubli doesn’t just pick one terminal shape and stick with it.

Because their MULTILAM contact system3 is flexible, it can maintain low resistance in both U-type and O-type terminals4.

Dive Deeper: MULTILAM Works for Both

MULTILAM is the tiny contact strip inside the MC4 that maintains spring pressure on the terminal pin. It adjusts itself to ensure:

- Reliable connection under vibration

- Resistance to corrosion and thermal cycling

- Over 25 years of field operation

Whether the pin is U-type or O-type, MULTILAM keeps the connection tight. It adapts to slight differences in shape without losing contact pressure.

That’s how Stäubli can offer both designs without sacrificing performance or safety.

Which Pin Type Performs Better in High-Current or High-Temperature PV Installations?

When the current rises, so does the heat. And that can change everything.

O-type terminals are more stable under high-current and high-temperature loads5, thanks to their solid cylindrical contact area.

Dive Deeper: Performance Under Pressure

In environments where ambient temperatures hit 60°C and current exceeds 30A:

- O-type terminals perform better because they have more uniform surface contact.

- U-type terminals are still safe, but depend more on perfect crimping.

Stäubli’s lab tests show lower contact resistance6 and less micro-arcing in O-type terminals over 10,000 cycles of thermal stress.

If you’re building solar arrays in deserts, industrial rooftops, or floating platforms—go with O-type.

Are U-Type or O-Type Pins More Common in Tier-1 Solar Projects?

Tier-1 solar projects rarely compromise on speed, consistency, or certification.

Most Tier-1 solar projects use O-type terminals because they come pre-crimped and meet factory-level quality standards7.

Dive Deeper: Why Tier-1 Favors O-Type

In my experience working with EPCs in Australia and Southeast Asia, procurement teams prefer O-type for these reasons:

- Fewer variables: Everything is factory-tested.

- Speed: No time wasted on crimping in the field.

- Compliance: Easier to meet TÜV and UL audit trails8.

However, U-type still has a place—especially in distributed or residential solar, where field teams cut cables to fit roof shapes or retrofitted carports.

How Do Stäubli’s Dual Pin Options Improve Installation Flexibility and Safety?

Here’s the smart part—Stäubli doesn’t lock you into one system. They give you options.

Dive Deeper: Why Dual Options Make Sense

- Installer Flexibility9: Field technicians can adapt to any site condition using U-type.

- Manufacturing Efficiency10: OEMs automate crimping and avoid human error with O-type.

- Global Compliance: Both terminal types pass TÜV/UL when used correctly.

More importantly, if a connector is properly installed—U or O type—it still benefits from MULTILAM technology11 and retains a 25-year rated lifespan.

Stäubli is playing the long game here: offering compatibility, safety, and ease of use to both ends of the solar industry.

Conclusion

Stäubli offers both U-type and O-type MC4 terminals because real-world solar projects need both flexibility and factory-grade precision.

-

Explore this link to understand the specific applications and benefits of U-type MC4 terminals in various projects. ↩

-

Learn about O-type terminals and their advantages in automated production processes, ensuring efficiency and reliability. ↩

-

Explore this link to understand the innovative MULTILAM contact system and its advantages in maintaining low resistance. ↩

-

Learn about U-type and O-type terminals to see how they impact performance and reliability in electrical connections. ↩

-

Understanding the impact of high-current and high-temperature loads can help optimize your PV system's design and efficiency. ↩

-

Learn about contact resistance and its significance in ensuring the longevity and efficiency of PV connectors in various environments. ↩

-

Exploring factory-level quality standards will help you grasp the importance of quality in solar installations. ↩

-

Learning about TÜV and UL audit trails is crucial for ensuring compliance and safety in solar projects. ↩

-

Understanding Installer Flexibility can enhance your knowledge of how to adapt to various site conditions effectively. ↩

-

Exploring Manufacturing Efficiency can reveal how automation improves production quality and reduces errors in solar panel assembly. ↩

-

Learning about MULTILAM technology will help you understand its advantages in enhancing connector performance and longevity. ↩