Why are Stäubli MC4 connectors the preferred choice for tier-1 module brands?

I see many buyers struggle with connector reliability, and this is a real problem because a single failure can shut down an entire PV string.

Stäubli MC4 connectors are preferred by tier-1 module brands because they offer stable performance, low contact resistance, and proven long-term safety in harsh environments.

Many importers and EPC teams ask me why top module brands insist on these connectors. I want to share what I have learned from real projects and daily work in PV connectivity.

What makes them more reliable than alternatives?

I meet many customers who worry about hidden connector failures because these issues often stay invisible until power loss or overheating happens.

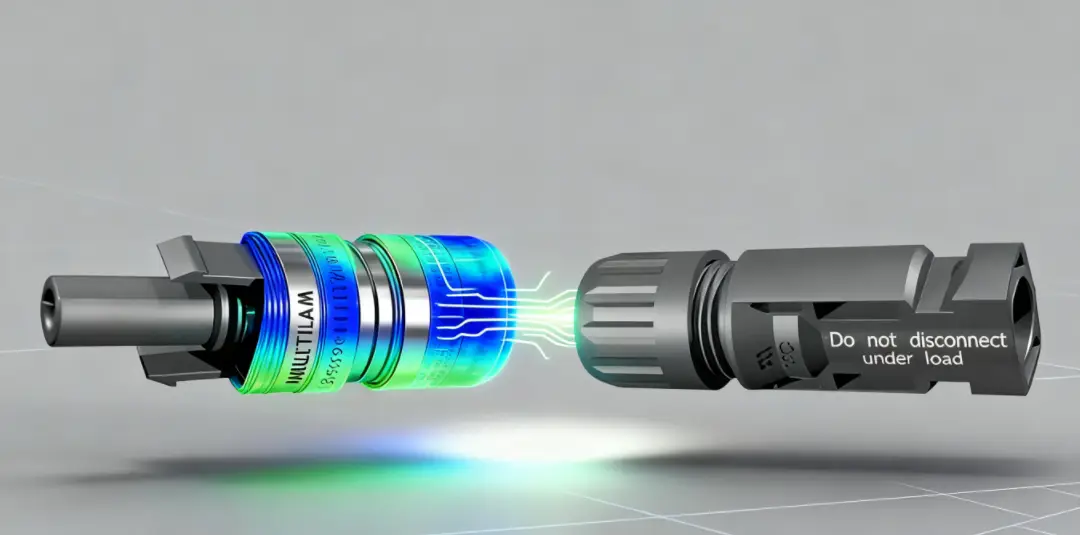

Stäubli MC4 stands out because its MULTILAM technology1 keeps contact resistance low for decades, which reduces heat, arcing, and long-term degradation.

Why this reliability matters in real installations

Stäubli MC4 connectors keep performance stable because of the way the contact system works. The MULTILAM contact band touches the pin at many small points. These points share the current flow evenly. This design limits heat buildup. It also reduces the chance of resistance increasing over time. When resistance stays low, the connector handles high currents safely.

I have seen this benefit on large solar farms where connectors operate under strong sunlight, high temperatures, and constant load for years. Many generic connectors lose performance after a few years because the metal surface degrades, or the spring force weakens. When that happens, the connector heats up and may cause thermal damage2.

Another reason Stäubli connectors stay reliable is their stable material quality3. The sealing parts resist UV, heat, humidity, and salt environment. This is important because many solar farms in coastal or desert regions face aggressive weather conditions. A stable sealing system keeps moisture out. This prevents corrosion from building up inside the contact area.

In many projects I support, EPCs report that systems using Stäubli connectors show fewer maintenance events4. When I review site reports, I often see that mixed-brand connectors cause failures. Stäubli-to-Stäubli mating is designed to eliminate this risk. This is also why investors prefer modules that use Stäubli connectors.

In short, Stäubli MC4 stays reliable because the internal design is stable, the sealing is strong, and the materials handle long-term outdoor stress better than most alternatives.

How does certification affect brand choice?

Many buyers misunderstand certification. They think certification is just a legal requirement. But for tier-1 module brands, certification shapes the entire product strategy.

Stäubli MC4 connectors5 hold strong IEC and UL certifications6 that help module brands meet global installation standards and reduce warranty risks.

Why certification influences module brand decisions

Certification is more than a label. It shows that a connector can survive real stress tests. Stäubli connectors pass tests for temperature cycles7, UV exposure, current load, and humidity. These tests simulate many years of outdoor operation. Tier-1 brands want connectors that meet these standards because they protect the module’s long-term warranty.

When I talk with module factories, their engineers often explain that they face consistency challenges when testing their modules with generic connectors. Some connectors pass once but fail in batch testing. Stäubli keeps very tight tolerances, so their performance is stable across manufacturing lots.

Certification also affects international shipments. Many countries require UL or IEC marks for compliance. Using certified connectors removes many inspection risks. In financed projects, banks also check component certifications. They want long-term assurance that every part of the PV system meets global standards.

Another thing customers overlook is that certification helps with after-sales service8. When the connector is certified, installers can replace parts safely and follow standard procedures. This reduces the chance of mismatched components. Stäubli’s global acceptance also makes it easier to pass third-party inspections.

Because of these reasons, certification is a major factor behind why tier-1 brands choose Stäubli MC4 connectors as their default option.

Can I compare durability with other connectors?

I get questions from importers almost every week asking how to compare Stäubli MC4 with generic options. Many products look similar from the outside. But performance differences become clear only after long-term exposure.

Stäubli MC4 connectors show stronger durability because they resist UV, heat, moisture, salt-mist, and mechanical stress far better than generic connectors.

[^9] resistant PV connector and cutaway view of rusted cracked connector](https://rayenrg.com/wp-content/uploads/2025/12/MC4-durability-comparison-4.webp)

How durability differs in real environments

Durability depends on how well a connector handles physical and environmental stress. Stäubli connectors keep their performance stable because each part has been designed to resist common outdoor risks. The contact surface does not degrade easily. The MULTILAM band stays elastic even after many cycles of heating and cooling. This keeps the spring force stable. A stable spring force means steady contact.

I have seen generic connectors fail early because their sealing materials soften after long exposure. When this happens, water enters the connector. Moisture leads to corrosion. When corrosion reaches the metal contact, the resistance rises. Rising resistance produces heat. Heat speeds up degradation. It becomes a chain reaction that ends in failure.

Stäubli connectors avoid this problem because their sealing materials come from higher-grade sources. Their lock mechanism is also stronger. I have noticed this difference when testing connectors in harsh sites such as coastal regions. Salt-mist exposure accelerates damage on low-quality connectors. But Stäubli units remain stable.

Another difference is mechanical strength9. Many installers use torque tools or pull cables during installation. Low-quality connectors crack easily. But Stäubli materials resist mechanical stress. This is important because many connectors sit under tension during the lifetime of the system.

Here is a simple comparison table:

| Feature | Stäubli MC4 | Generic MC4-like |

|---|---|---|

| Contact resistance stability | Very stable | Often unstable |

| UV resistance10 | High | Medium |

| Salt-mist resistance | High | Low |

| Lock reliability | Strong | Weak |

| Lifetime expectation | 25+ years | 5–10 years |

| Bankability | Global standard | Often fails audits |

When I review failure reports, I see the same pattern. Stäubli connectors show much fewer cases of melting, discoloration, or cracking. This makes them a safer option for large-scale projects.

Are they worth the higher price?

Many buyers ask me this because Stäubli connectors do cost more than generic options. But the price difference is small compared to the risk avoided.

Yes, Stäubli MC4 connectors are worth the higher price because they reduce long-term maintenance costs11, prevent failures, and help protect project bankability12.

Why paying more makes sense in real solar projects

The higher cost of Stäubli connectors becomes easy to justify when I look at the complete lifetime of a solar project. A connector failure in a utility-scale project can cause large downtime losses. It also requires skilled technicians to find and fix the issue. In some cases, the cost of a single truck roll exceeds the cost of hundreds of high-quality connectors.

Another important factor is bankability. Investors want components with a strong track record. Stäubli MC4 connectors have millions of installations worldwide. This proven record helps projects pass technical due diligence. Using low-quality connectors increases the chance of inspection failure. This can delay project approval.

I also see cost impact on EPC contractors. When Stäubli connectors are used, installation becomes easier because each connector mates perfectly with the next. This reduces installation errors13. Generic connectors often cause mismatch or loose mating. These issues increase the chance of hot spots later.

In the long run, the difference in lifetime performance is even bigger. Many generic connectors degrade after a few years. This increases heat and resistance. When connectors fail early, they reduce system yield. Stäubli connectors maintain their performance for decades, which protects energy output.

The price difference at the material level is small. But the value gained from reliability, safety, and long service life is much higher.

Conclusion

Stäubli MC4 connectors cost more, but they deliver safer, more stable, and more durable performance across the full lifetime of modern solar projects.

-

Explore how MULTILAM technology enhances connector reliability and performance, ensuring long-lasting stability. ↩

-

Understand the causes of thermal damage in connectors and how to choose products that minimize this risk. ↩

-

Learn about the significance of stable material quality in connectors and how it impacts performance in harsh environments. ↩

-

Discover the benefits of using Stäubli connectors in reducing maintenance needs and enhancing system reliability. ↩

-

Explore the advantages of Stäubli MC4 connectors, including their certifications and reliability in solar applications. ↩

-

Learn why IEC and UL certifications are crucial for ensuring safety and compliance in electrical components. ↩

-

Understand the impact of temperature cycles on connector durability and performance in solar energy systems. ↩

-

Discover how certification enhances after-sales service and ensures safe replacements in electrical installations. ↩

-

Learn how mechanical strength impacts connector reliability and longevity, especially in demanding installations. ↩

-

Discover why UV resistance is crucial for outdoor connectors to ensure long-lasting performance and prevent degradation. ↩

-

Learn how managing long-term maintenance costs can significantly impact the overall budget and success of solar projects. ↩

-

Discover why bankability is crucial for attracting investors and ensuring the success of solar energy projects. ↩

-

Find out how to minimize installation errors to enhance the efficiency and reliability of solar energy systems. ↩